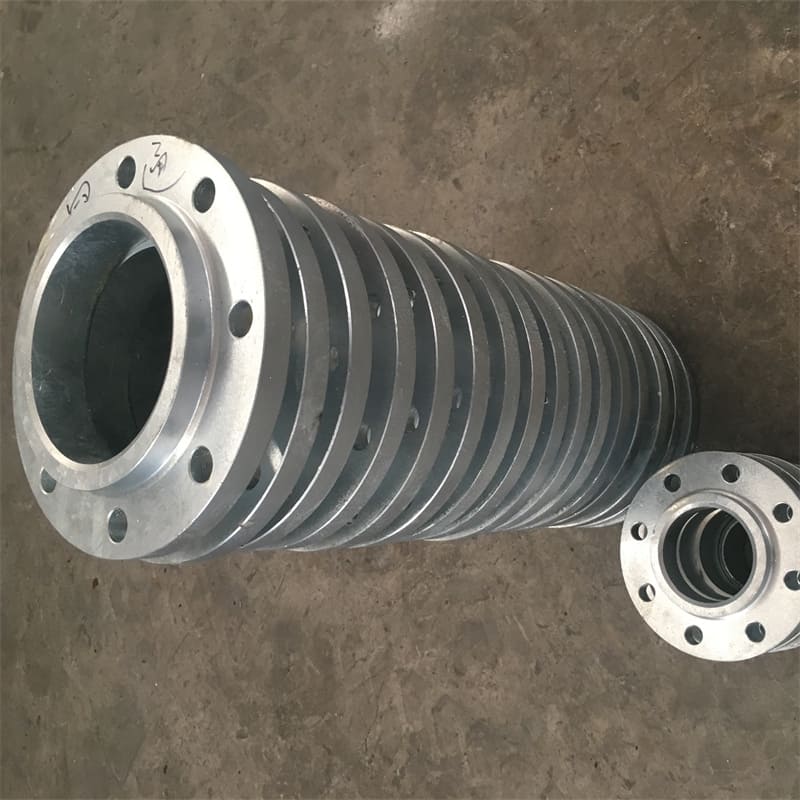

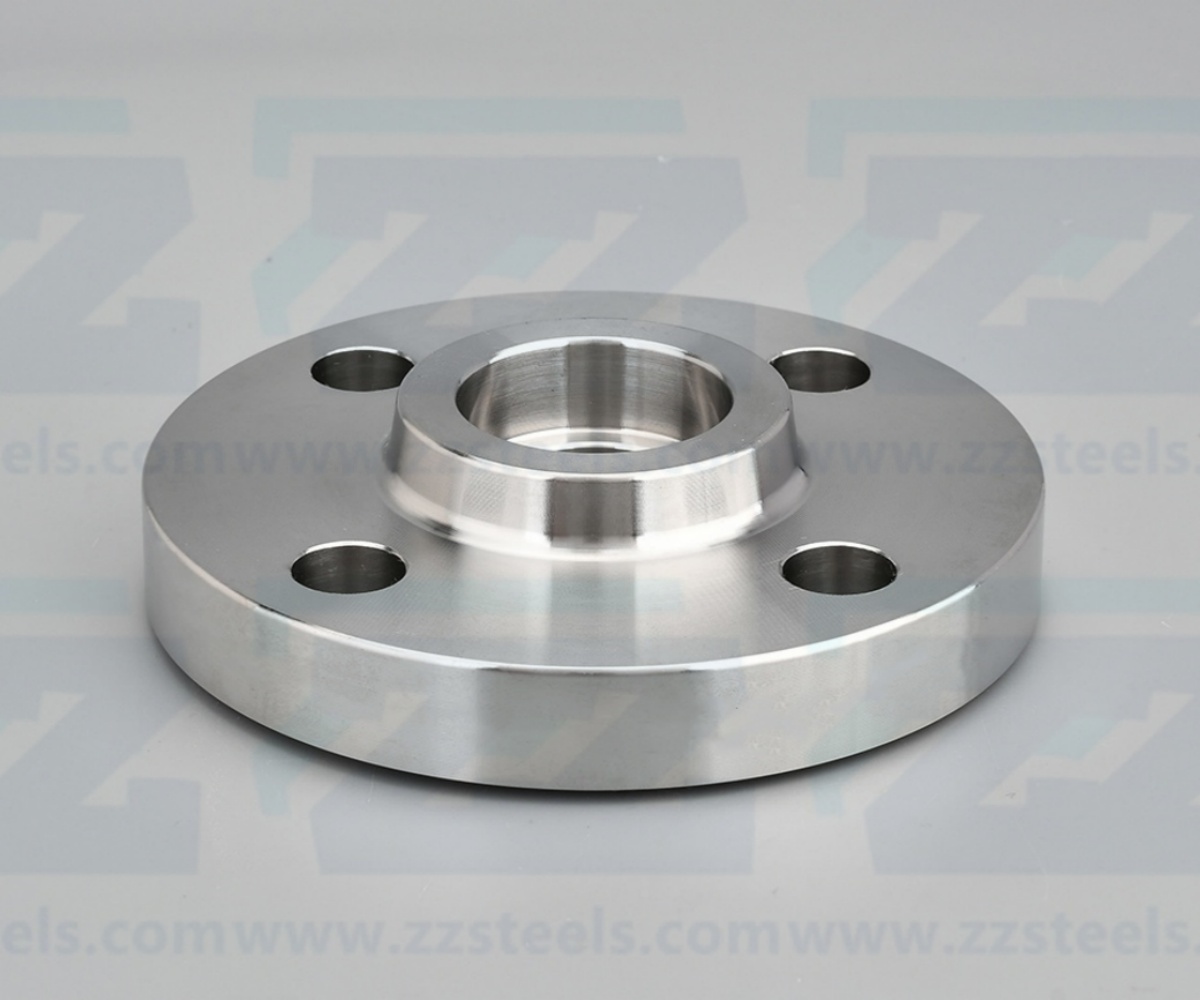

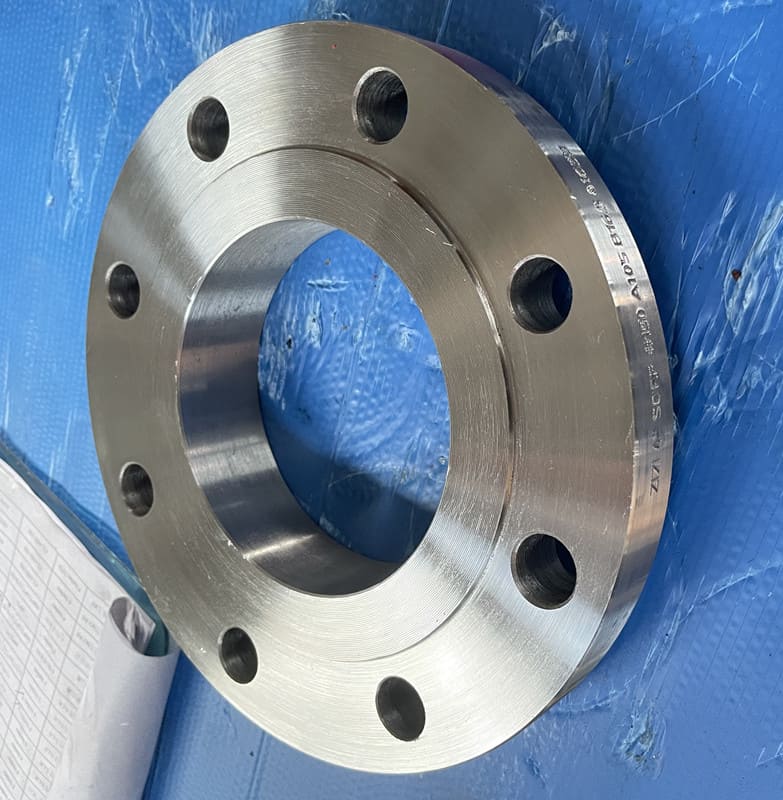

ASTM A182 F904L Flange

ASTM A182 F904L Flange is a non-stabilized austenitic stainless steel with low carbon content. This high alloy stainless steel is added with copper to improve its resistance to strong reducing acids, such as sulphuric acid. The steel is also resistant to stress corrosion cracking and crevice corrosion.

ASTM A182 F904L Flange is a standard specification developed by the American Society for Testing and Materials (ASTM) for high-temperature forged or rolled alloy steel and stainless steel pipe flanges, forged pipe fittings, valves and components. This standard has strict regulations on the chemical composition, mechanical properties, manufacturing process, inspection methods and other aspects of the material to ensure that these components can operate safely and reliably under harsh environments such as high temperature and high pressure.

F904L material is a super austenitic stainless steel. On the basis of ordinary austenitic stainless steel, it adjusts the content of alloy elements to make it have better corrosion resistance, especially in resisting corrosion in chloride ion media, and is suitable for various strong corrosive environments.

ASTM A182 F904 Flange Material

ASTM A182 F904L Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Ti | Cu |

| ASTM A182 F904L (N08904) | MIN | 23.00 | 19.00 | 4.00 | 1 | |||||||

| MAX | 0.02 | 2.00 | 0.040 | 0.030 | 1.00 | 28.00 | 23.00 | 5.00 | 0.10 | 2.00 |

ASTM A182 F316 Mechanical Property

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F904L | 490 min | 215 min | 35 min | 50 min |

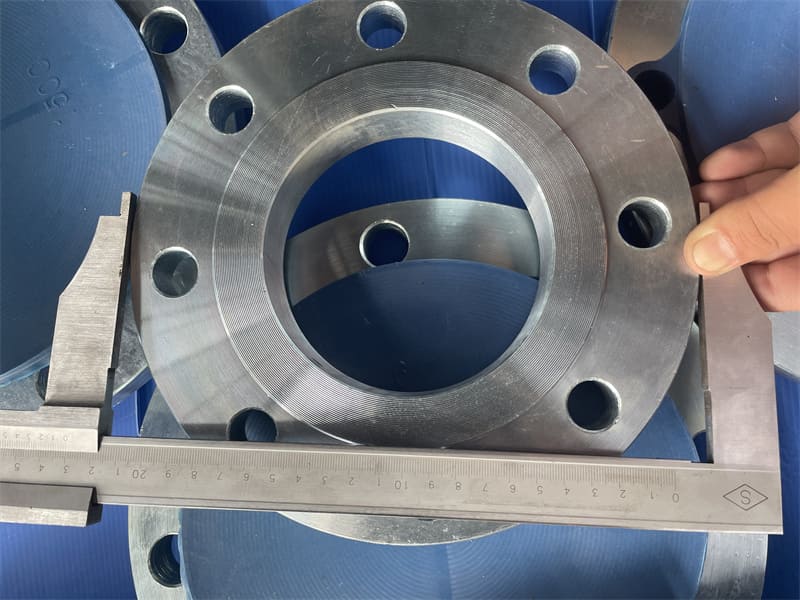

Dimensions of Class 150 ASTM A182 F904L Flanges

| Nominal Pipe Size, NPS |

Outside Diameter of Flange, O |

Minimum Thickness of Flange, tf [Notes (2)-(4)] |

Minimum Thickness Lap Joint, tf |

Diameter of Hub, X |

Hub Diameter Beginning of Chamfer Welding Neck, Ah [Note (5)] |

Length Through Hub | Minimum Thread Length Threaded, T [Note (6)] |

Bore | Welding Neck/ Socket Welding, B [Note (7)] |

Corner Bore Radius of Lapped Flange and Pipe, r |

Depth of Socket, D |

|||

| Threaded/ Slip-on/ Socket Welding, Y |

Lapped, Y |

Welding Neck, Y |

Minimum Slip-on/ Socket Welding, B |

Minimum Lapped, B |

||||||||||

| 1/2 | 90 | 9.6 | 11.2 | 30 | 21.3 | 14 | 16 | 46 | 16 | 22.2 | 22.9 | 15.8 | 3 | 10 |

| 3/4 | 100 | 11.2 | 12.7 | 38 | 26.7 | 14 | 16 | 51 | 16 | 27.7 | 28.2 | 20.9 | 3 | 11 |

| 1 | 110 | 12.7 | 14.3 | 49 | 33.4 | 16 | 17 | 54 | 17 | 34.5 | 34.9 | 26.6 | 3 | 13 |

| 1 1/4 | 115 | 14.3 | 15.9 | 59 | 42.2 | 19 | 21 | 56 | 21 | 43.2 | 43.7 | 35.1 | 5 | 14 |

| 1 1/2 | 125 | 15.9 | 17.5 | 65 | 48.3 | 21 | 22 | 60 | 22 | 49.5 | 50.0 | 40.9 | 6 | 16 |

| 2 | 150 | 17.5 | 19.1 | 78 | 60.3 | 24 | 25 | 62 | 25 | 61.9 | 62.5 | 52.5 | 8 | 17 |

| 2 1/2 | 180 | 20.7 | 22.3 | 90 | 73.0 | 27 | 29 | 68 | 29 | 74.6 | 75.4 | 62.7 | 8 | 19 |

| 3 | 190 | 22.3 | 23.9 | 108 | 88.9 | 29 | 30 | 68 | 30 | 90.7 | 91.4 | 77.9 | 10 | 21 |

| 3 1/2 | 215 | 22.3 | 23.9 | 122 | 101.6 | 30 | 32 | 70 | 32 | 103.4 | 104.1 | 90.1 | 10 | |

| 4 | 230 | 22.3 | 23.9 | 135 | 114.3 | 32 | 33 | 75 | 33 | 116.1 | 116.8 | 102.3 | 11 | |

| 5 | 255 | 22.3 | 23.9 | 164 | 141.3 | 35 | 36 | 87 | 36 | 143.8 | 144.4 | 128.2 | 11 | |

| 6 | 280 | 23.9 | 25.4 | 192 | 168.3 | 38 | 40 | 87 | 40 | 170.7 | 171.4 | 154.1 | 13 | |

| 8 | 345 | 27.0 | 28.6 | 246 | 219.1 | 43 | 44 | 100 | 44 | 221.5 | 222.2 | 202.7 | 13 | |

| 10 | 405 | 28.6 | 30.2 | 305 | 273.0 | 48 | 49 | 100 | 49 | 276.2 | 277.4 | 254.6 | 13 | |

| 12 | 485 | 30.2 | 31.8 | 365 | 323.8 | 54 | 56 | 113 | 56 | 327.0 | 328.2 | 304.8 | 13 | |

| 14 | 535 | 33.4 | 35.0 | 400 | 355.6 | 56 | 57 | 125 | 57 | 359.2 | 360.2 | Note(8) | 13 | |

| 16 | 595 | 35.0 | 36.6 | 457 | 406.4 | 62 | 64 | 125 | 64 | 410.5 | 411.2 | Note(8) | 13 | |

| 18 | 635 | 38.1 | 39.7 | 505 | 457.0 | 67 | 68 | 138 | 68 | 461.8 | 462.3 | Note(8) | 13 | |

| 20 | 700 | 41.3 | 42.9 | 559 | 508.0 | 71 | 73 | 143 | 73 | 513.1 | 514.4 | Note(8) | 13 | |

| 24 | 815 | 46.1 | 47.7 | 663 | 610.0 | 81 | 83 | 151 | 83 | 616.0 | 616.0 | Note(8) | 13 | |

Application Fields

Chemical Industry: In chemical production, many media are highly corrosive, such as sulfuric acid, hydrochloric acid, sodium hydroxide, etc. F904L flanges are widely used in the connection parts of chemical pipeline systems, reactors, storage tanks and other equipment due to their excellent corrosion resistance, ensuring the safety and stability of chemical production.

Marine Engineering: There are a large number of chloride ions in the marine environment, which are highly corrosive to metal materials. F904L flanges can resist the corrosion of seawater and are suitable for marine engineering facilities such as offshore platforms, submarine pipelines, and seawater desalination equipment to ensure the long-term operation of marine engineering.

Food and Pharmaceutical Industry: In the process of food and pharmaceutical production, the hygiene requirements for pipelines and equipment are very high, and it is also necessary to prevent materials from contaminating products. F904L stainless steel has good hygiene and corrosion resistance, meets the strict requirements of the food and pharmaceutical industries, and can be used for related pipeline connections and equipment manufacturing.