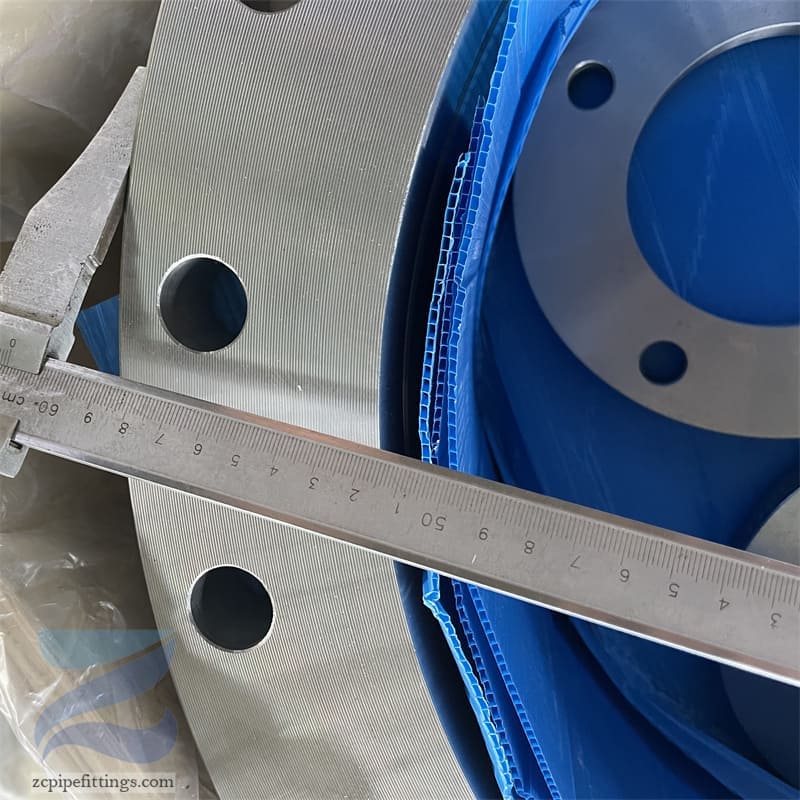

ASTM A182 F51 Duplex Stainless Steel Flange

Duplex stainless steel flange is a flange made of duplex stainless steel. Duplex stainless steel refers to a solid solution structure in which the ferrite phase and the austenite phase each account for about half, and the minimum content of the phase generally needs to reach 30%.

Duplex stainless steel flange is a flange made of duplex stainless steel. Duplex stainless steel refers to a solid solution structure in which the ferrite phase and the austenite phase each account for about half, and the minimum content of the phase generally needs to reach 30%. The existence of this two-phase structure makes duplex stainless steel have the advantages of both ferrite stainless steel and austenite stainless steel.

The metallographic structure of duplex stainless steel consists of ferrite phase and austenite phase. Under normal heat treatment conditions, the ferrite phase and austenite phase are evenly distributed to form an intertwined microstructure. This unique metallographic structure gives duplex stainless steel excellent comprehensive properties.

The Characteristics of ASTM A182 F51 Material

Chemical composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | |||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 |

Mechanical properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| ASTM A182 F51 | 620 min | 450 min | 25 min | 45 min |

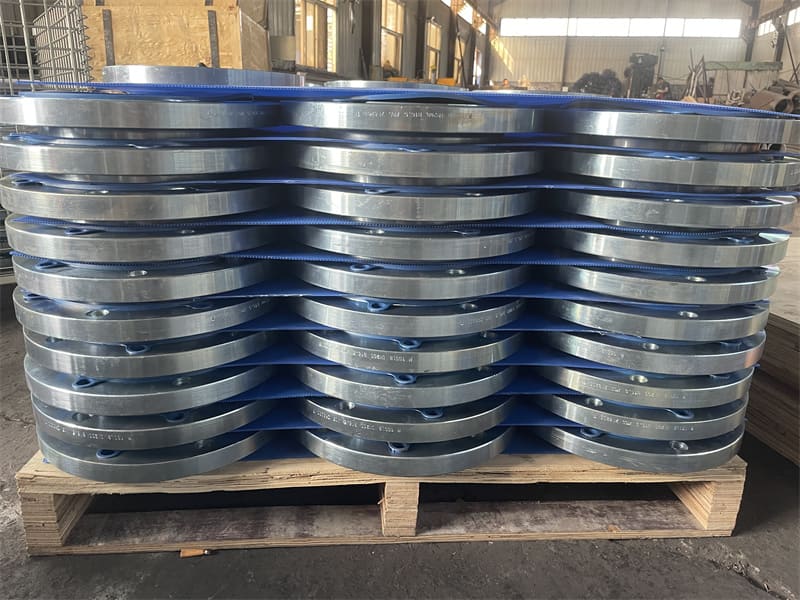

Classification of ASTM A182 F51 Flanges

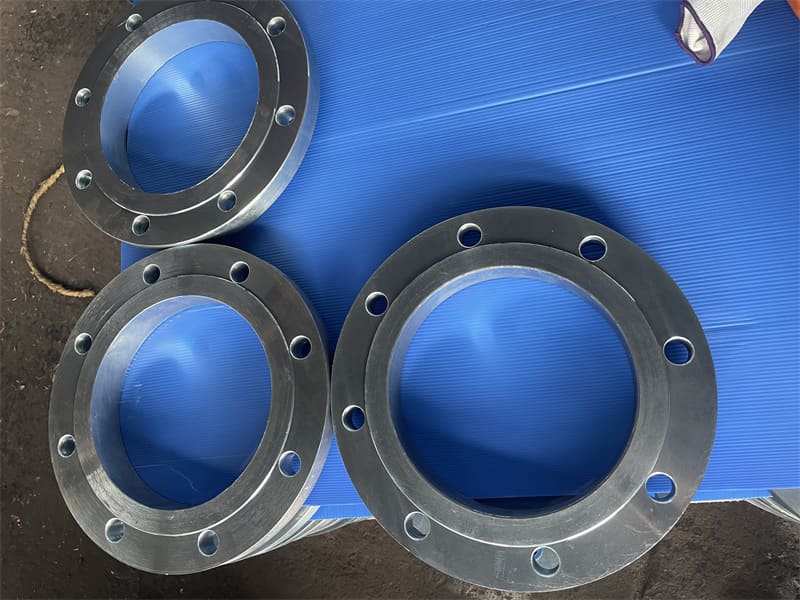

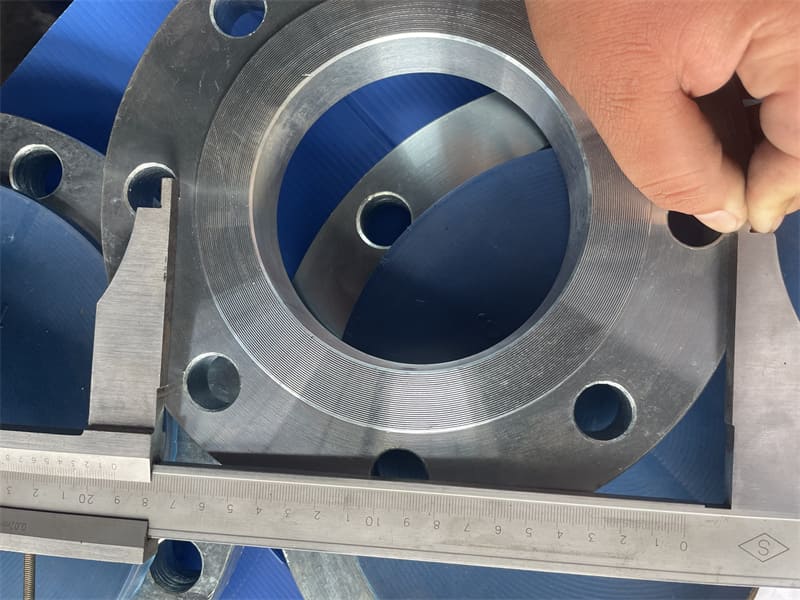

ASTM A182 F51 flanges can be divided into six categories: duplex stainless steel blind flanges, slip on flanges, socket weld flanges, threaded flanges, weld neck flanges, and lap joint flanges.

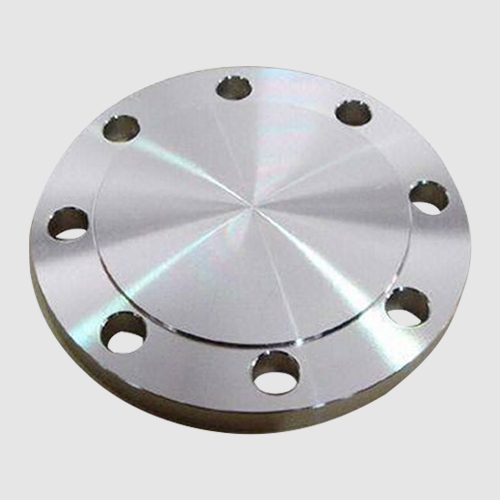

Blind flange: A blind flange is a solid flange with no holes for fluid to pass through.

Socket weld flange: A socket weld flange has a socket and spigot structure.

Threaded flange: The main feature of a threaded flange is that it is connected by threads. It has internal or external threads and is connected to pipes or pipe fittings with corresponding external or internal threads.

Weld neck flange: A weld neck flange is connected by butt welding the flange to the pipe.

Lap joint flange: A lap joint flange uses a flange, steel ring, etc. to put the flange on the pipe end so that the flange can move on the pipe end.

Slip on flange: A slip on flange is a flange that connects the flange to the pipe through a fillet weld.

Application fields

Petrochemical industry: In the process of oil and natural gas extraction, refining and chemical production, duplex stainless steel flanges are often used in pipeline systems, reactors, heat exchangers and other equipment that transport corrosive media.

Marine engineering field: Due to the presence of a large number of chloride ions in the marine environment, metal materials are extremely corrosive. Duplex stainless steel flanges are widely used in marine engineering facilities such as offshore platforms, ships, and submarine pipelines due to their excellent resistance to seawater corrosion.

Food and pharmaceutical industry: In the process of food processing and pharmaceutical production, the hygiene requirements and corrosion resistance requirements for equipment are very high. Duplex stainless steel flanges have good corrosion resistance and hygiene properties, and can be used in the connection parts of food processing equipment, pharmaceutical reactors, storage tanks and other equipment.