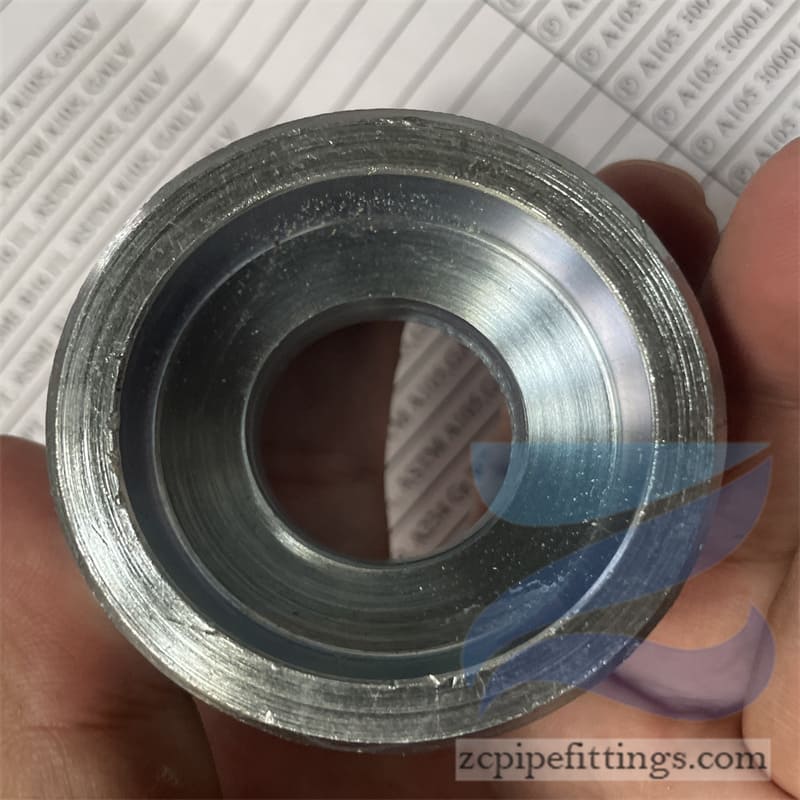

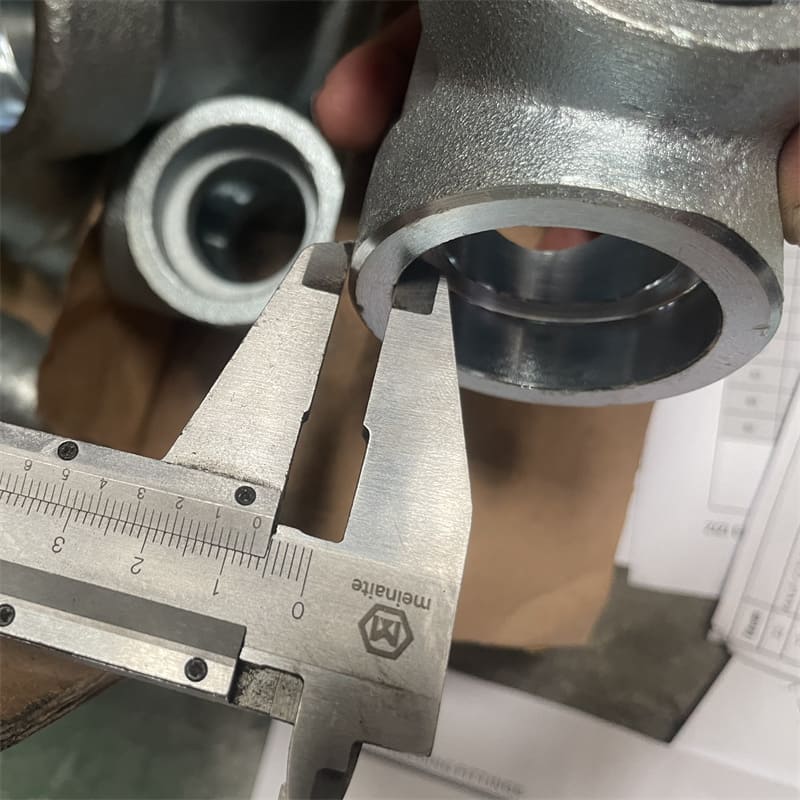

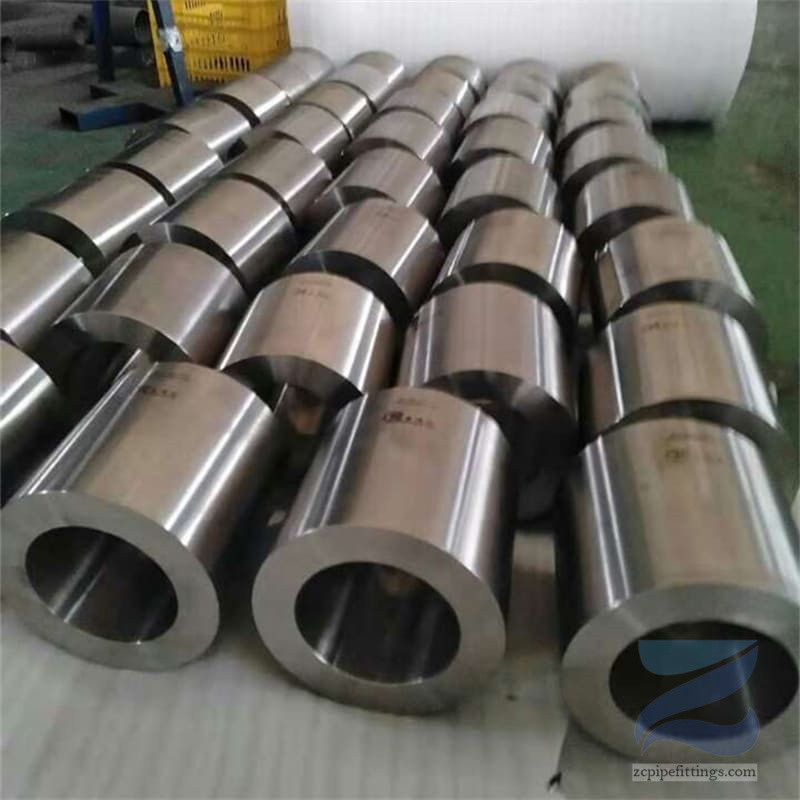

ASTM A182 F316 Socket Weld Couplings ASME B 16.11 Forged Fittings

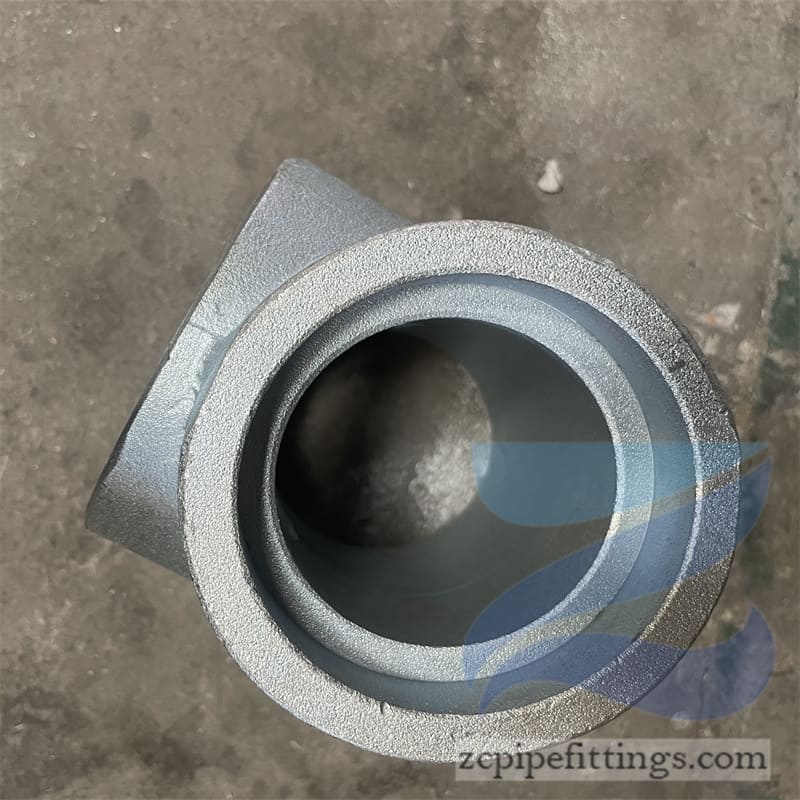

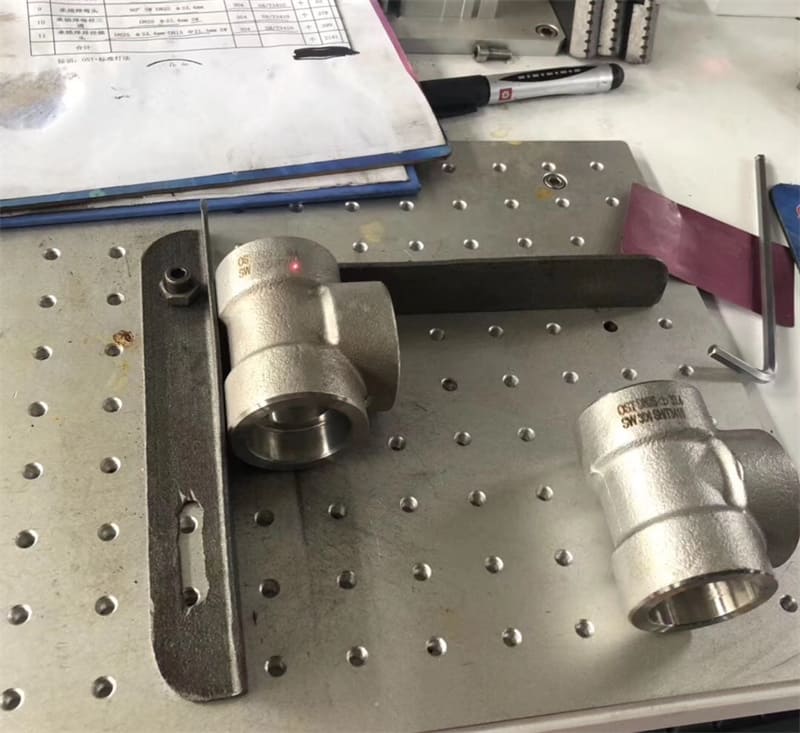

ASTM A182 F316 socket weld couplings are used in many industires because stainless steel have a very long using period.SW fittings are belong to ASME B16.11 forged fittings,only can used with small size pipes in ASME Standard.The pressures have #3000,#6000,#9000 to choose.

ASTM A182 F316 socket weld couplings have great performance in many chemical environments because of the superior anti-corrosive function.ASME B 16.11 forged fittings including threaded (THD) pipe fittings and socket weld (SW) fittings.

Types of Couplings:

Full Couplings:

Both end of the couplings are socketed or threaded.

Half Couplings:

One end is threaded or socketed while the other end used welding type to connection.

Shapes of Couplings:

Straight Couplings:

It is a kind of pipe coupling with the same diameter at both ends.

Reducing Couplings:

The two ends of the coupling have different sizes,so that could reduce the flow in the piping systems.

Advantages of SW fittings

- Socket weld fittings have great performance of anti-leakage.

- The connected pipes do not have to be beveled.

- Affordable price

Disadvantages of SW fittings

- Socket weld pipe fittings can not be used in corrosive industries because the welded place can be corrodes easily.

SW Fittings VS BW Fittings

SW fittings are easy to install while BW fittings require a great skill for welding.BW fittings have more wide range in applications,but the price of BW fittings are more expensive.SW fittings are affordable,but these fittings have a limitation in applications,SW fittings can only used for small diameter pipelines.

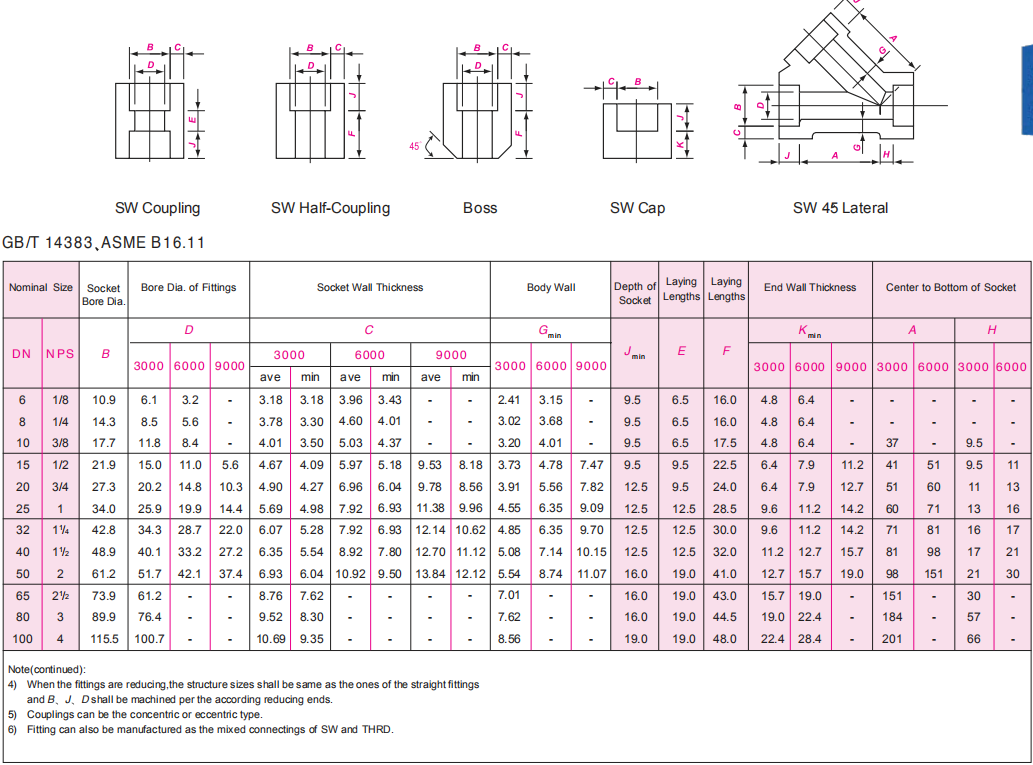

Specification

| Shape | Coupling |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |