ASTM A182 F316 Pipe Nipples ASME B16.11 Forged Fittings

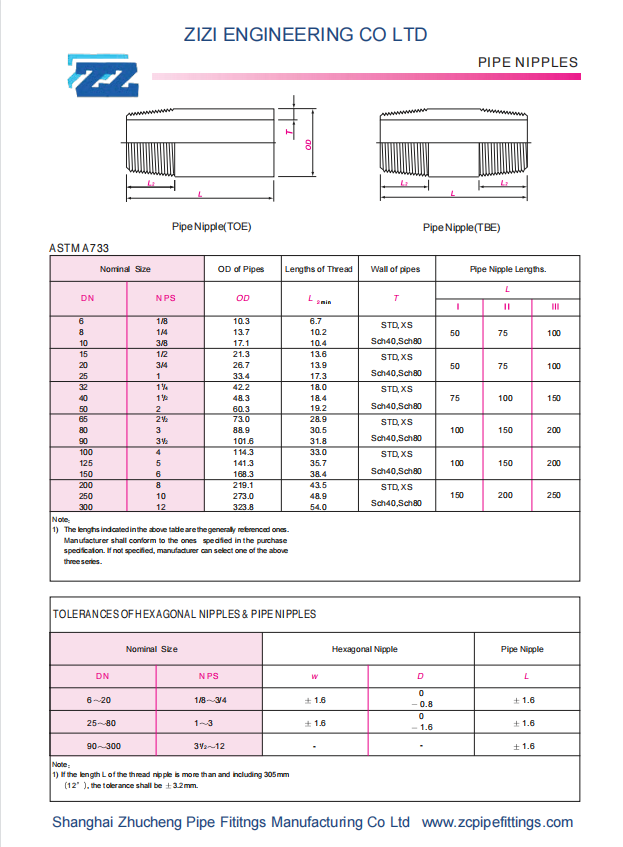

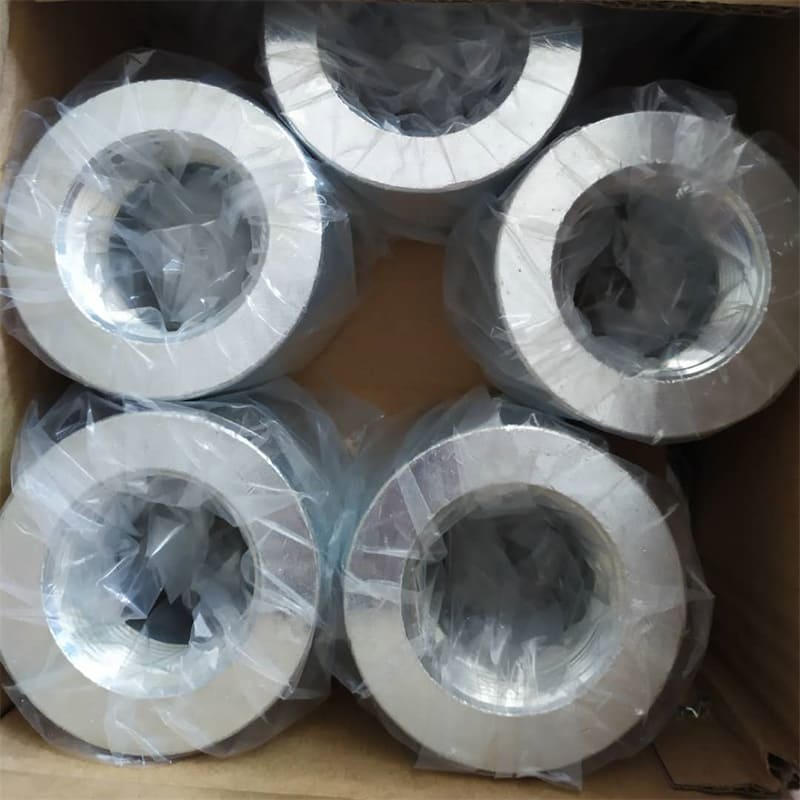

ASTM A182 F316 pipe nipples have two shapes:TOE (threaded one end) and TBE (threaded both ends).The nipples in the picture are all in TOE shape.The pressures can be chosen:CL2000,CL3000,CL6000.

ASTM A182 F316 pipe nipples are widely used in corrosive environments worked as a junction in piping systems.ASME B16.11 forged fittings including both threaded fittings and socket weld fittings,used with high pressure applications.

Shapes:

Threaded One End(TOE):

One end of this kind of nipple is threaded and the other end is welded

Threaded Both End(TBE):

The nipple is threaded at both ends

Advantages:

- Shorten construction period and improve project quality.

- Reducing energy consumption is conducive to environmental protection.

- Reduce equipment investment and low additional cost.

Application:

Forged Threaded Fittings Pipe Nipple are designed for wide use in different industries,such as oil refineries, chemical processing, petrochemical and many other industries. These pipe fittings can withstand high temperature and high pressure.

Specification

| Shape | Nipple |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

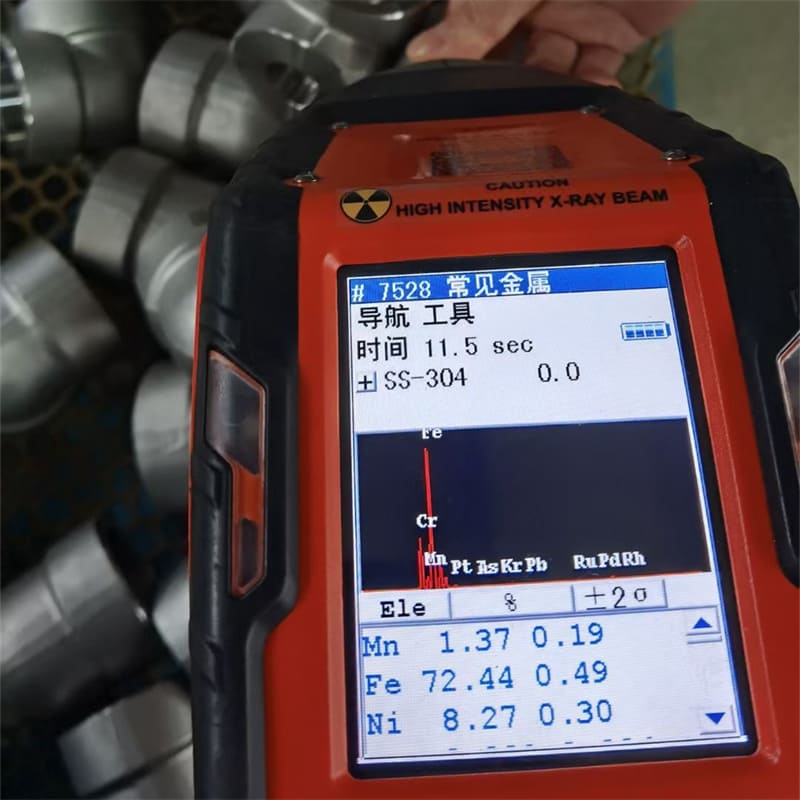

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |