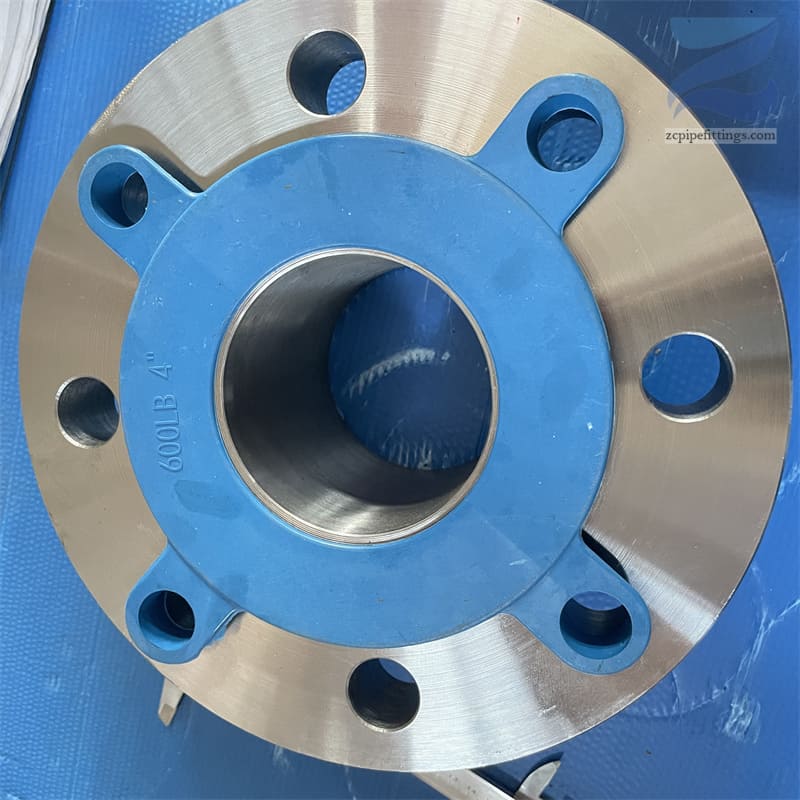

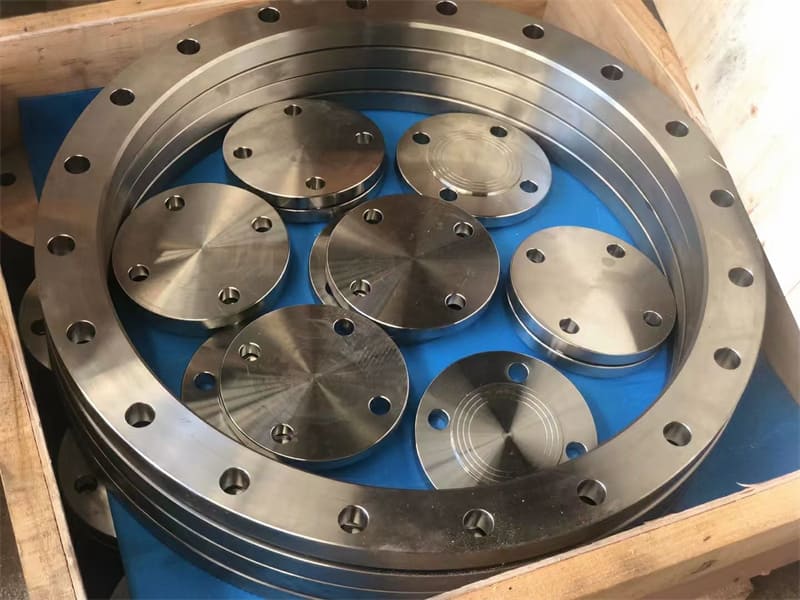

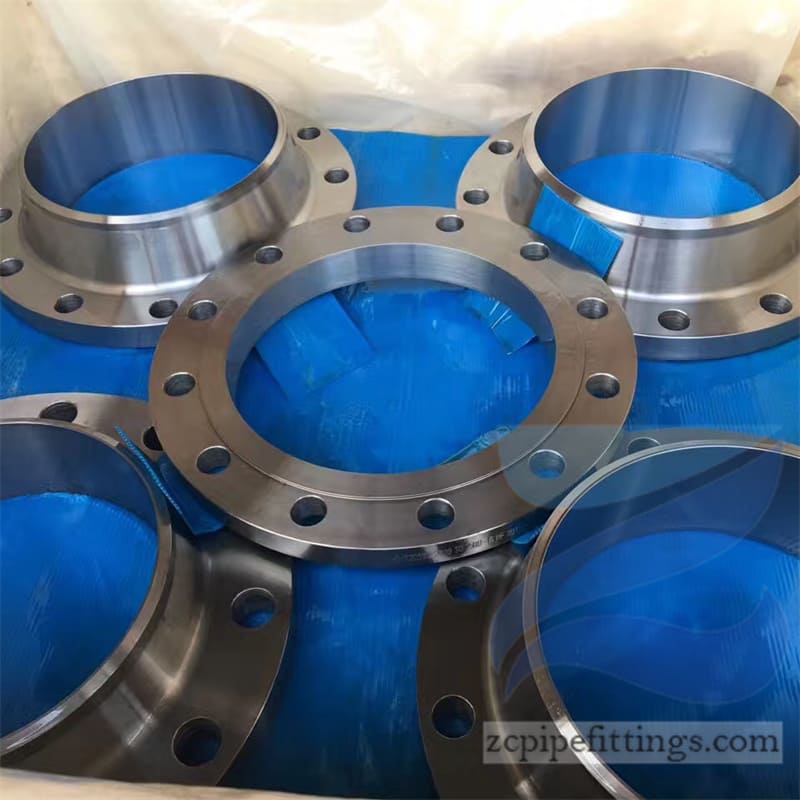

ASTM A182 F316 Lap Joint Flange

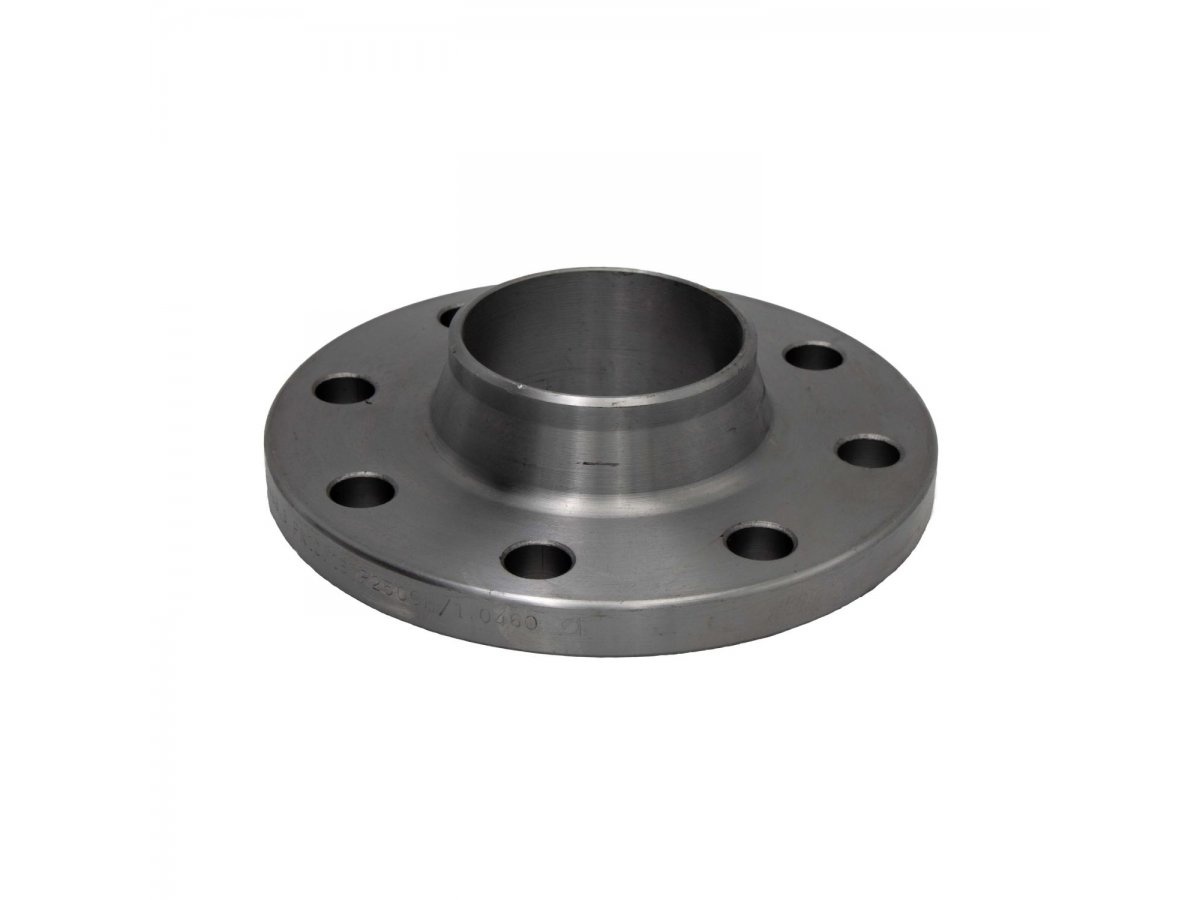

Stainless steel lap joint flange is a flange connection component, which consists of a flange, a flanged short section or a butt welding ring. Among them, the flange is made of stainless steel, which has good corrosion resistance, heat resistance and other properties.

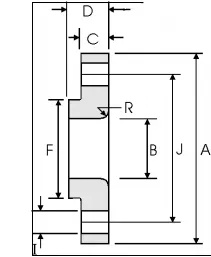

ASTM A182 F316 lap joint flange is a flange connection component, which consists of a flange, a flanged short section or a butt welding ring. Among them, the flange is made of stainless steel, which has good corrosion resistance, heat resistance and other properties. The meaning of lap joint is that its connection method is relatively flexible. For a lap joint flange with a neck, it has a short neck, one end of which is welded to the pipe, and the other end can be relatively freely matched with the flange. This structure allows the pipeline to have a certain expansion and contraction space when it expands and contracts or is subjected to a certain external force, reducing the stress concentration at the connection between the pipeline and the flange.

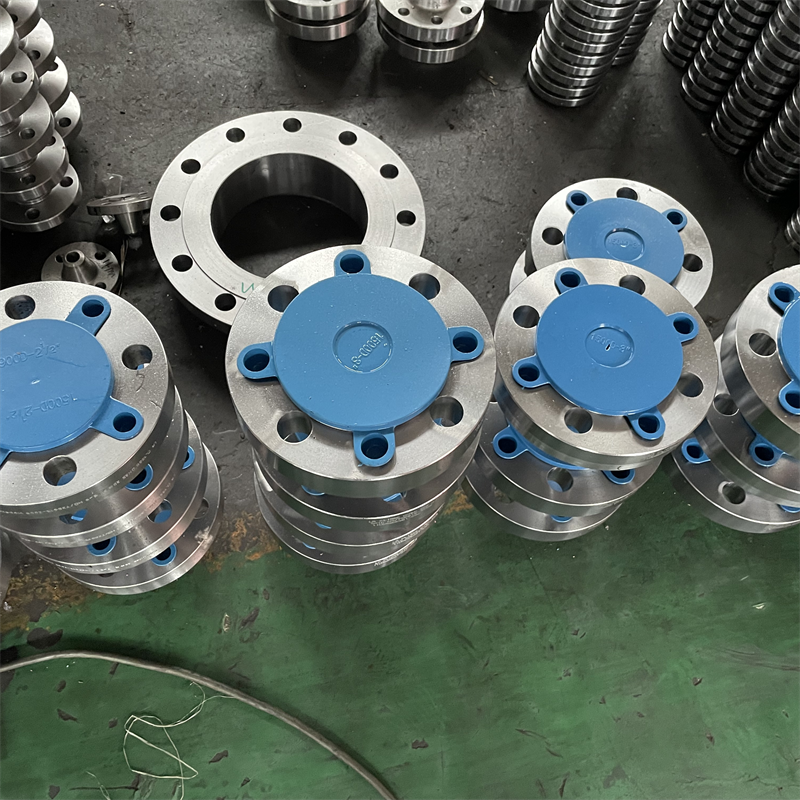

Compared with ordinary flanges, stainless steel lap joint flanges have certain advantages in installation and maintenance. During installation, due to its loose sleeve structure, it is easier to align the bolt holes, which facilitates the connection operation of the pipeline.