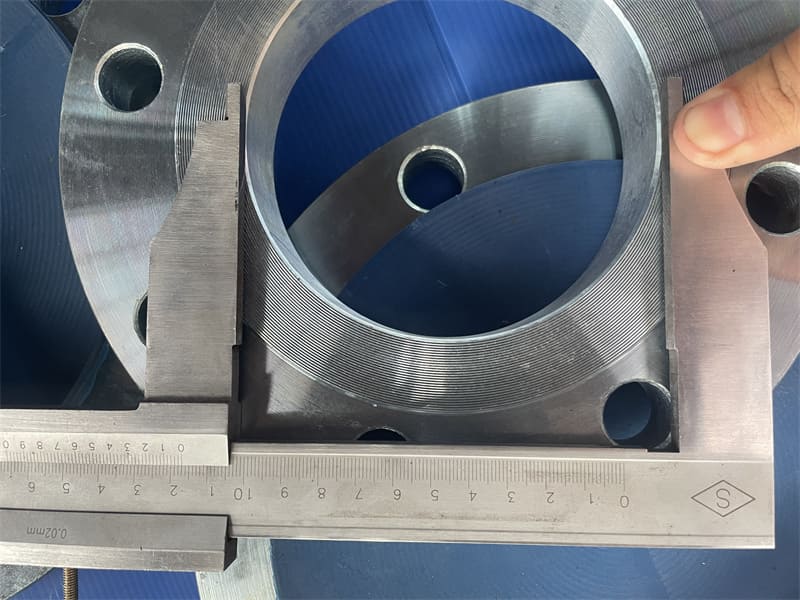

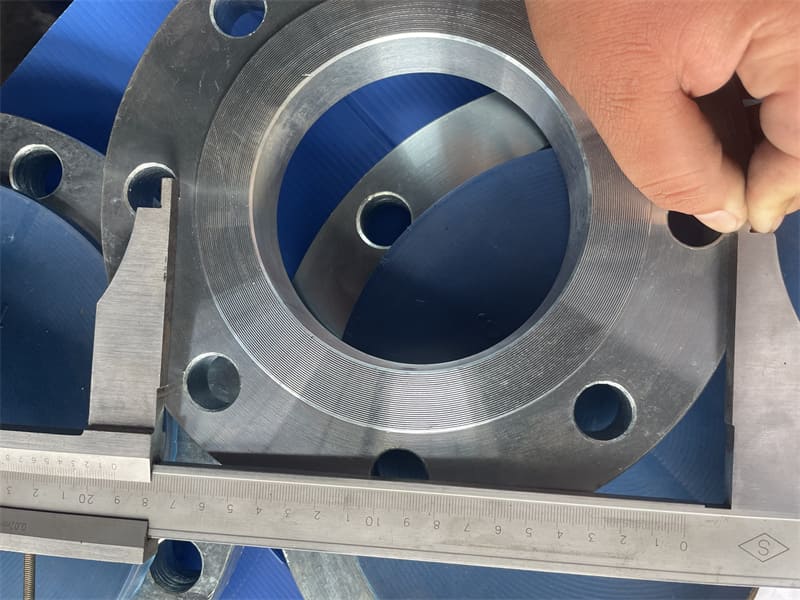

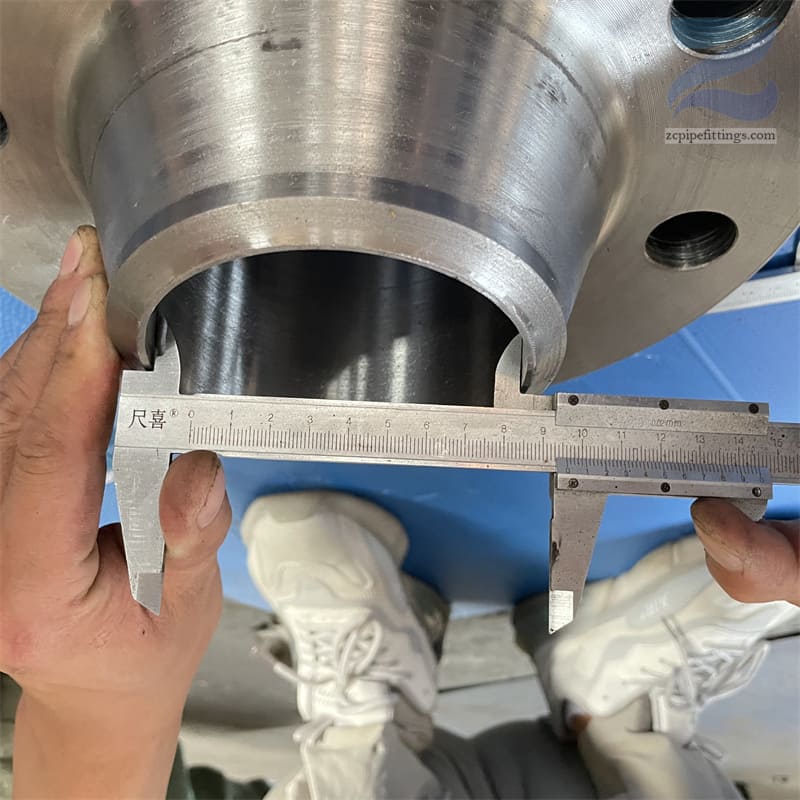

ASTM A182 F304L Large Size Weld Neck Flange

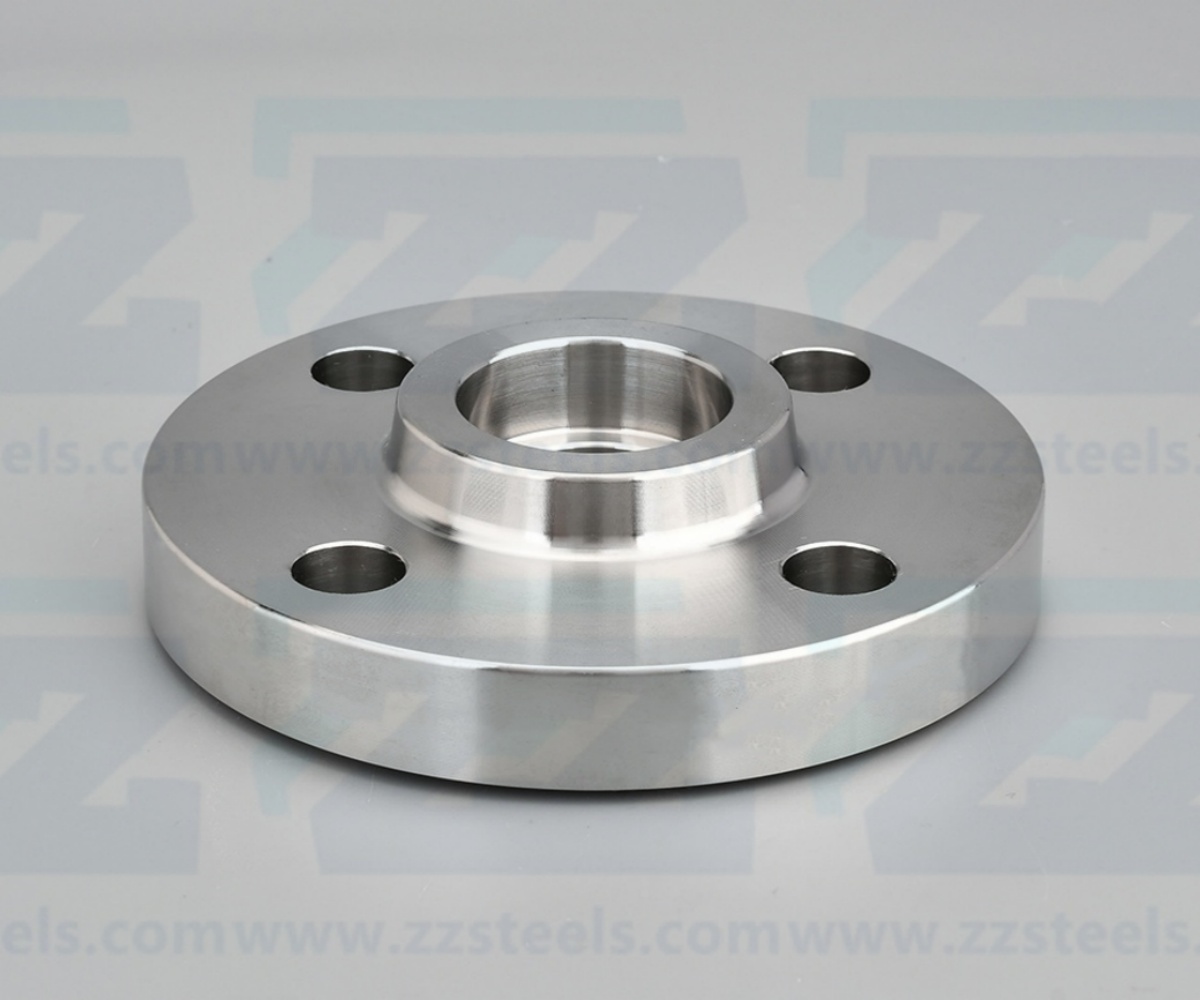

Weld Neck Flanges are a very common type of pipe flanges used in various industrial applications. They have a long tapered hub and are often used for high pressure applications.

A weld neck flange is a type of pipe flange that incorporates a cast-in neck that is welded to the pipe. Unlike a plain flange that is slipped over the pipe prior to being welded into place, a weld neck flange has a spout-like neck that is beveled to match up to the pipe. Once the pipe is beveled to match the weld neck flange, a perfect V shape is created in which a butt weld is placed to connect the two components. The benefit of a weld neck flange is that the welded connection does not interfere with the flow of liquid through the flange. By placing the weld joint at the end of the funnel-like neck of the flange, the pipe is much easier to align to the flange, and a stronger weld is typically possible with this type of flange. The flange’s neck is also perfectly beveled to demonstrate the type of bevel that the welder must place on the pipe before making the connection with the flange.

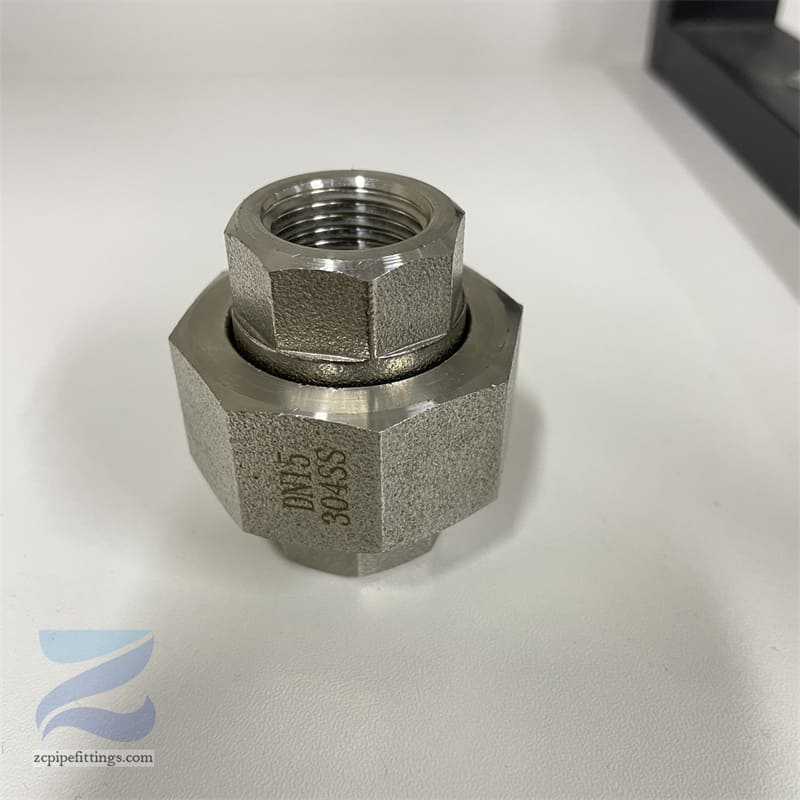

| Shape | Weld Neck Flange ( WN),Slip-on Flange (SO), Threaded Flange (THD),Socket Weld Flange (SW),Blind Flange (BL),Lap Joint Flange (LAPJ),Plate flange (PL) |

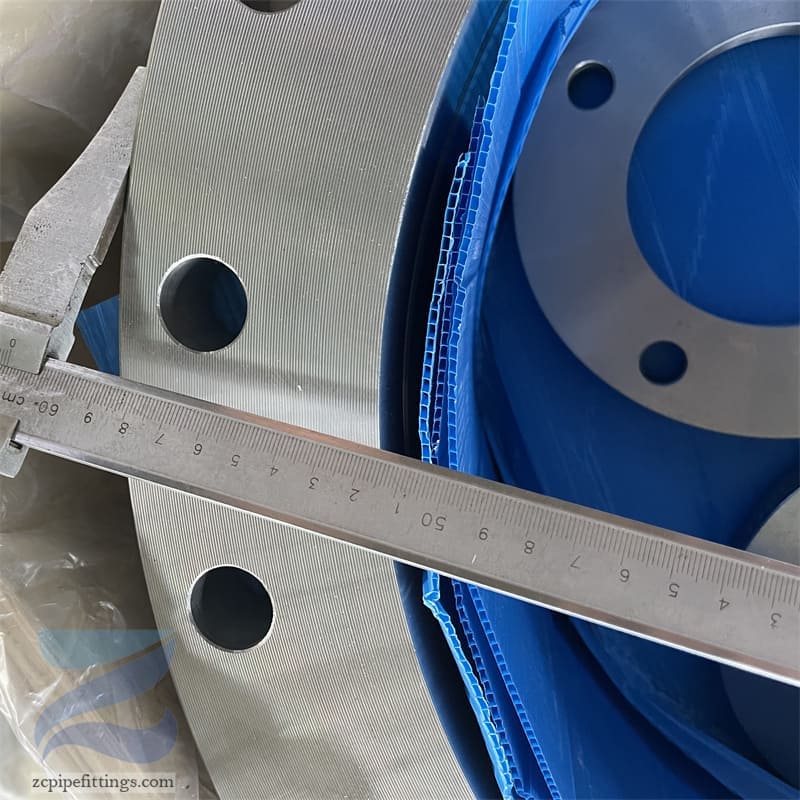

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

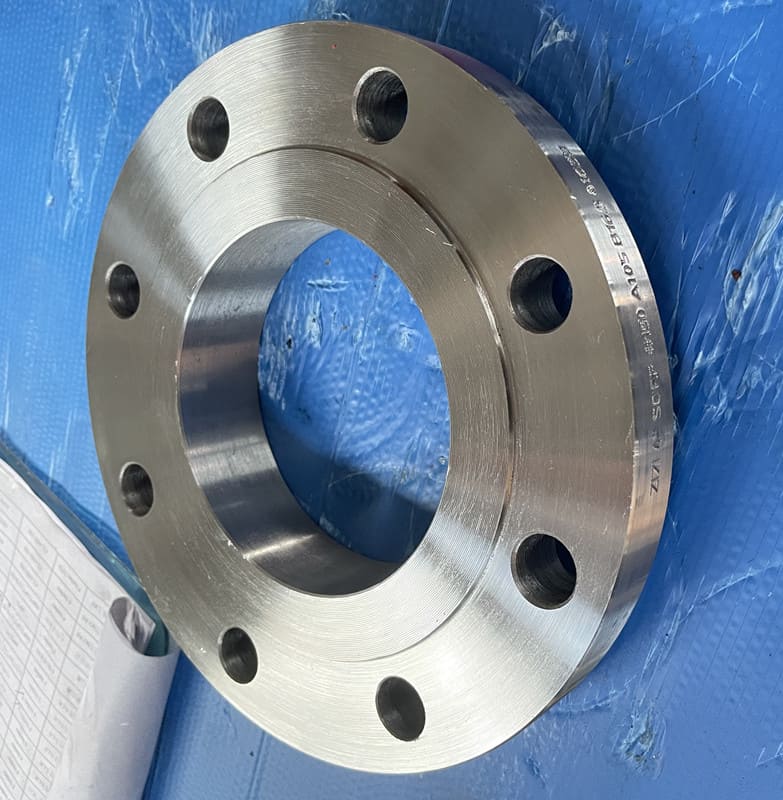

| Standard | ASME B16.5, ASME B16.47 Series A/B, EN 1092-1, API 605, MSS SP-44, DIN 2627, DIN 2527, DIN 2558, DIN 2576, DIN 2641, DIN 2655, DIN 2656, DIN2573 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Key Features:

This is the most common type of high pressure pipe flange.

They are distinguished from other types of pipe flanges by their long tapered hub and gentle transition of thickness in the region of the butt weld joining them to the pipe.

The long tapered hub provides an important reinforcement of the weld neck flange proper in terms of strength and resistance to dishing.

Class 150 lb Weld Neck Flange Dimensions & Weight

Notes:

1) Dimension B corresponds to the pipe inside diameter. Values quoted assume 40S/Standard wall thickness.

2) Weights are based on manufacturer’s data and are approximate .

3) Flat face flanges may be provided at full thickness, C, or with raised face removed (the latter is nonstandard).

4) The blank space needs to be provided by purchaser.

5) If you need class 300 ,600 ,900 ,1500 ,2500 flange dimensions & weight,please contact us.