ASTM A182 F304 Threaded Union

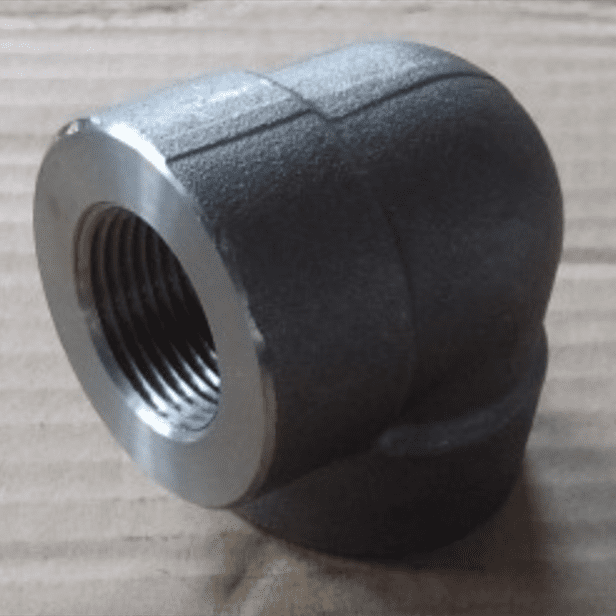

ASTM A182 F304 Threaded Union is a specialized piping component designed for quick and secure disconnection and reconnection of pipes. This union features female National Pipe Taper (NPT) threads on both ends, facilitating seamless integration with male-threaded pipe sections. It is primarily used to simplify the installation, maintenance, and inspection processes in complex piping systems.

ASTM A182 F304 Threaded Union is a specialized piping component designed for quick and secure disconnection and reconnection of pipes. This union features female National Pipe Taper (NPT) threads on both ends, facilitating seamless integration with male-threaded pipe sections. It is primarily used to simplify the installation, maintenance, and inspection processes in complex piping systems.

The threaded union offers robust mechanical strength, high corrosion resistance, and extended service life under harsh operational conditions. These properties make it suitable for a wide range of industrial applications, including oil and gas, chemical processing, and power generation, where system integrity and reliability are critical.

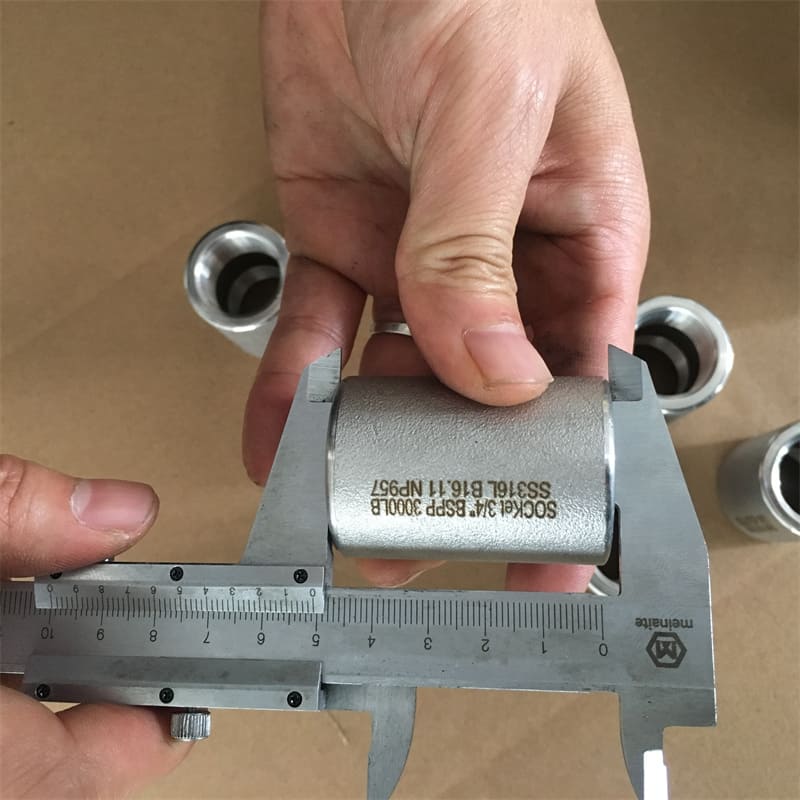

Specification of Class 3000 Threaded Union

The sizes of threaded union range from 1/8″ to 3″, and the pressure is Class 3000.

| Size | 1/8″ to 3″ ( DN6 to DN80) |

| Pressure Rating | Class 3000 |

| Standard | MSS SP-83 |

| Type | Socket Weld Union and Threaded Union |

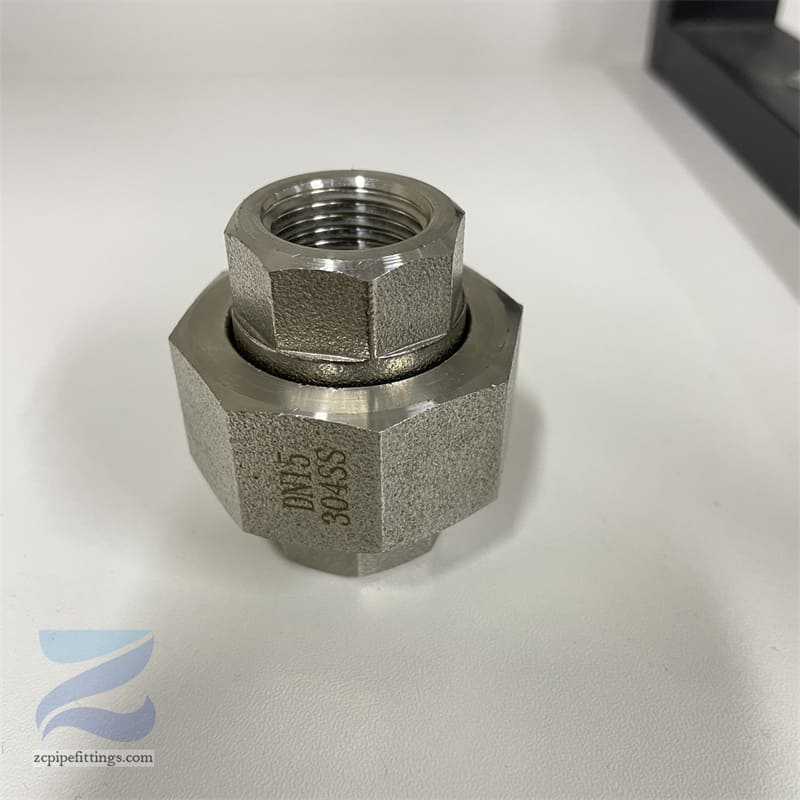

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / F12 / F5 / F9 / F91 / F92 / F22 |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F310S, F317, F347, F904L/F51/F55 |

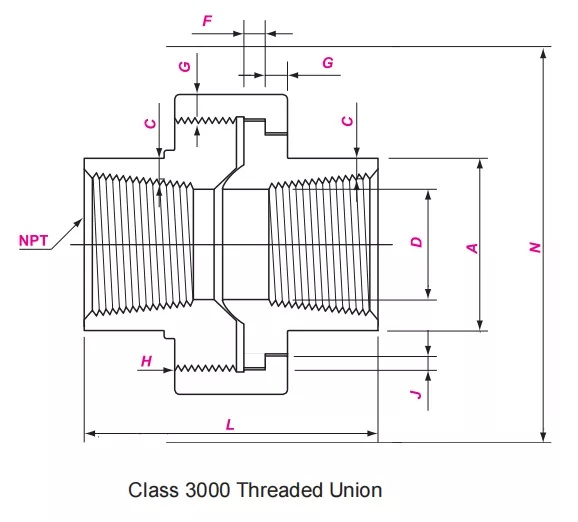

Dimension of Class 3000 Threaded Union

| Nominal Size | Pipe End | Wall | Bone | Male Flange | Nut | THRD Per Inch | Bearing | Length Assem | Clear Assem Nut | |

| DN | NPS | A min | C min | D | F min | G min | H | J min | L nom | N |

| 6 | 1/8 | 14.7 | 2.4 | 8.4 6.4 |

3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 8 | 1/4 | 19.1 | 3.0 | 11.1 9.4 |

3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 10 | 3/8 | 22.9 | 3.2 | 14.3 13.5 |

3.4 | 3.4 | 14 | 1.4 | 46.0 | 56 |

| 15 | 1/2 | 27.7 | 3.7 | 17.9 17.1 |

3.7 | 3.7 | 14 | 1.5 | 49.0 | 59 |

| 20 | 3/4 | 33.5 | 3.9 | 23.0 21.4 |

4.1 | 4.1 | 11 | 1.7 | 56.9 | 66 |

| 25 | 1 | 41.4 | 4.5 | 29.0 27.7 |

4.6 | 4.4 | 11 | 1.9 | 62.0 | 79 |

| 32 | 11/4 | 50.5 | 4.9 | 37.7 35.4 |

5.3 | 5.2 | 10 | 2.1 | 71.1 | 94 |

| 40 | 11/2 | 57.2 | 5.1 | 43.5 41.2 |

5.8 | 5.6 | 10 | 2.3 | 76.5 | 112 |

| 50 | 2 | 70.1 | 5.5 | 55.6 52.1 |

6.6 | 6.4 | 10 | 2.7 | 86.1 | 132 |

| 65 | 21/2 | 85.3 | 7.0 | 66.3 64.3 |

7.5 | 7.1 | 8 | 3.1 | 102.4 | 150 |

| 80 | 3 | 102.4 | 7.6 | 82.6 77.3 |

8.3 | 8.0 | 8 | 3.5 | 109.0 | 176 |

Advantages of ASTM A182 F304 Threaded Union

Disassembly

Compared with welded connections, stainless steel threaded unions can be easily disassembled. This is very beneficial during maintenance, overhaul or equipment replacement of the pipeline system. For example, in the water supply and drainage system of a building, if a certain pipe section has a problem, the pipe connected with the threaded union can be quickly disassembled and the problematic part replaced without cutting and re-welding the pipe, which greatly shortens the repair time.

Corrosion Resistance

Due to the use of stainless steel, stainless steel threaded unions have good corrosion resistance. In the chemical, food, beverage and other industries, the pipeline system is often exposed to various corrosive media, such as acid, alkali, salt solution, etc. Stainless steel threaded unions can resist the erosion of these media and ensure the long-term and stable operation of the pipeline system.

Easy Installation

The installation of stainless steel threaded unions is relatively simple. You only need to align the male and female heads, and then rotate them to achieve the connection. No special installation tools are required (in most cases), and an ordinary wrench can complete the installation operation.