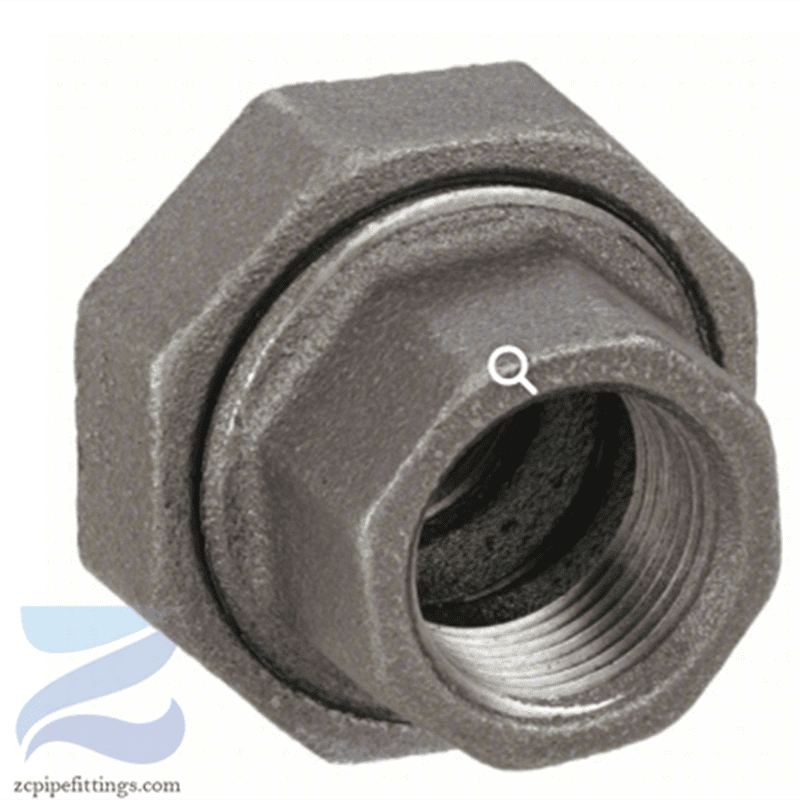

What is a threaded coupling?

A threaded coupler is a device designed for joining various types of threaded parts to one another. While there are several different types of couplers an individual can choose from, most couplers are designed for specific applications. For example, some couplers are designed to join threaded rods together, while others are only intended for joining lengths of pipe. The primary difference between couplers for rods and those meant for pipes is what is known as the thread pitch.

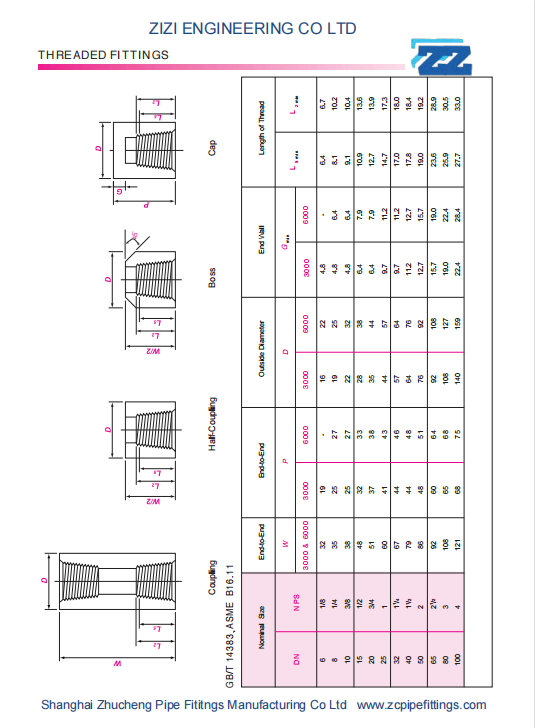

Specification of THD coupling

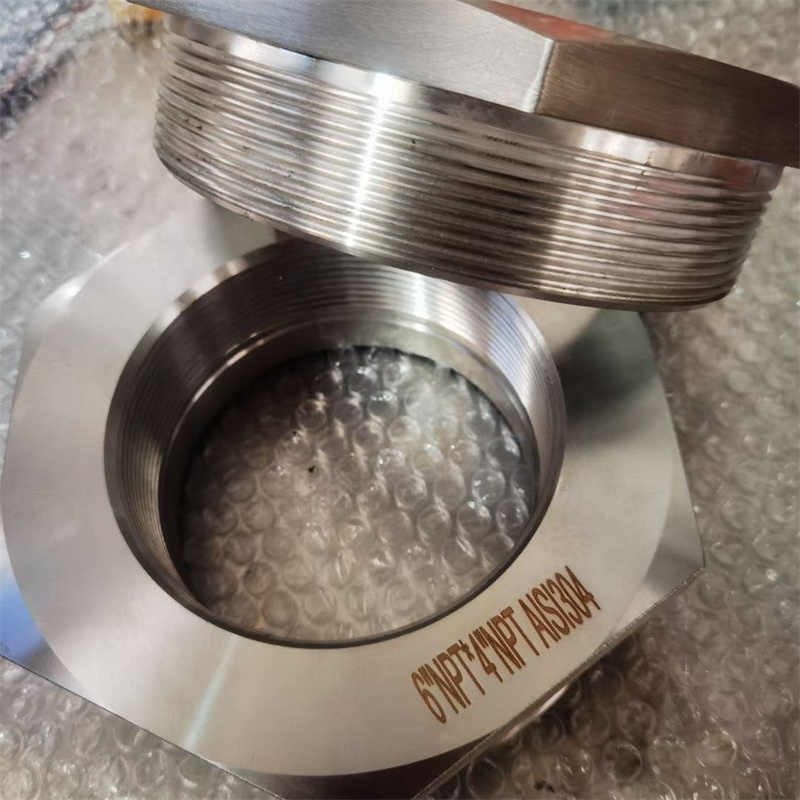

Size Range1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1-1/2″, 2″, 2-1/2″, 3″, 4″

Pressure RatingClass 3000, 6000

StandardASME B16.11, BS3799, EN 10241

Carbon Steel GradesASTM A105 / A105N / ASTM A350 LF2

Alloy Steel GradesASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22

Stainless Steel GradesASTM A182 F304/304L, F316/316L, F310S, F317, F347, F904L, F51, F53, F44, F55

Advantagse of THDcouplings

Firstly, threaded fittings have high joint strength, according to the principle of cold work hardening steel on steel rolling straight thread strength greatly increased, so that the straight thread connection of tensile strength is higher than the tensile strength of steel.

Next, threaded fittings provide stable and consistent performance, and therefore the connection process is not affected by the quality of the worker.

Moving on, threaded fittings can be connected swiftly, because use of over-the-counter precast, field assembly connection manner, so steel prepared wirehead can be prefabricated reinforced yards of reserves.

Additionally, threaded fittings are easy to manage, won’t appear in the sleeve and if the phenomenon of the steel bar does not match, the test is more convenient.