Home » Forged Steel Flanges » ASTM A182 304L Stainless Steel Socket Weld Flange ANSI / ASME B16.5

Content

What is a SW Flange?

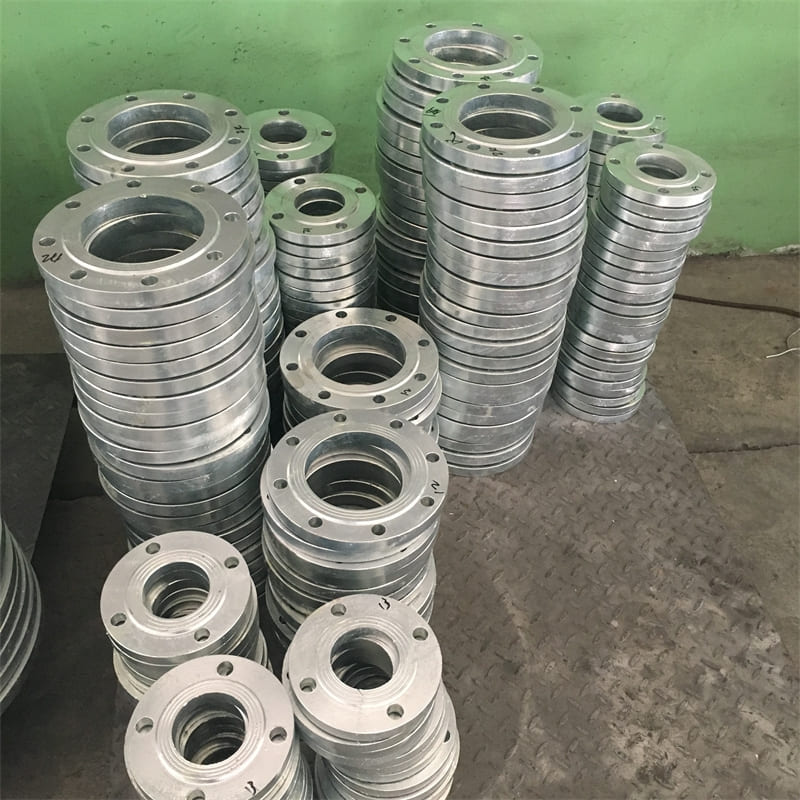

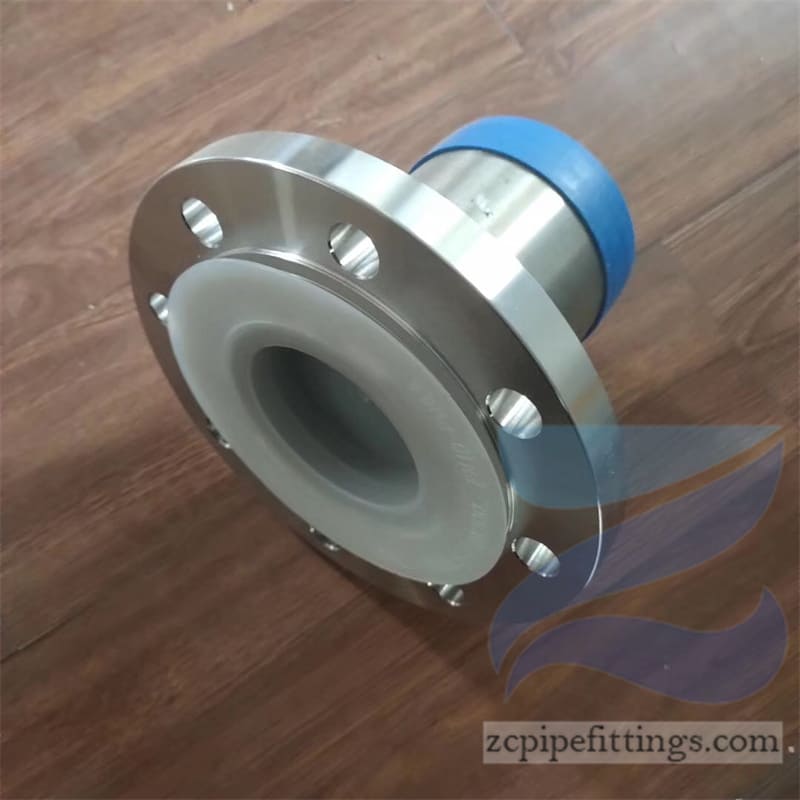

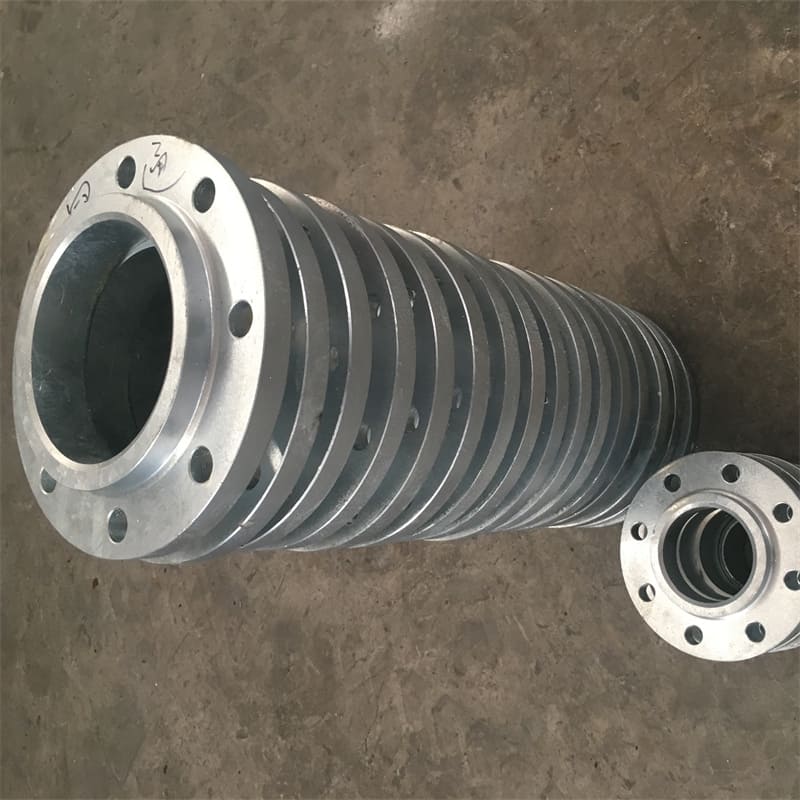

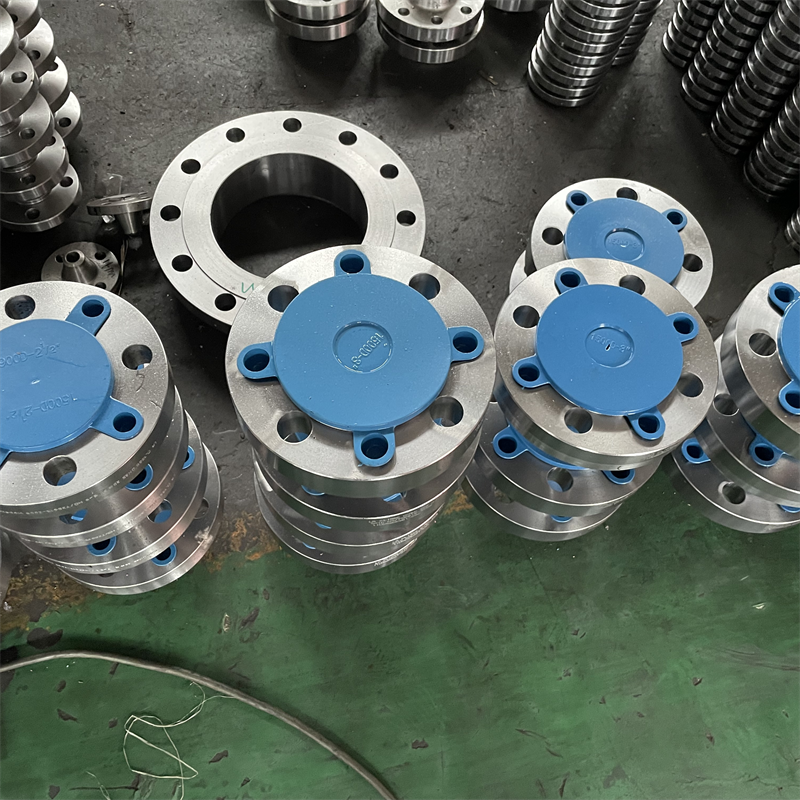

Socket weld flange is designed as the pipe is inserted into it’s bore and single fillet weld on the outside of flange. It is common used for small diameter high-pressure piping system. To some extent, it is smilar to slip on flange.Forged steel flange is a disc-shaped piece of equipment used to connect a pipe to fittings or valve or other component to form a pipework system. Usually flange has been attached to pipe or tube end to, and then a gasket is inserted in the middle to form a seal. Finally they are joined together with bolts and nuts.

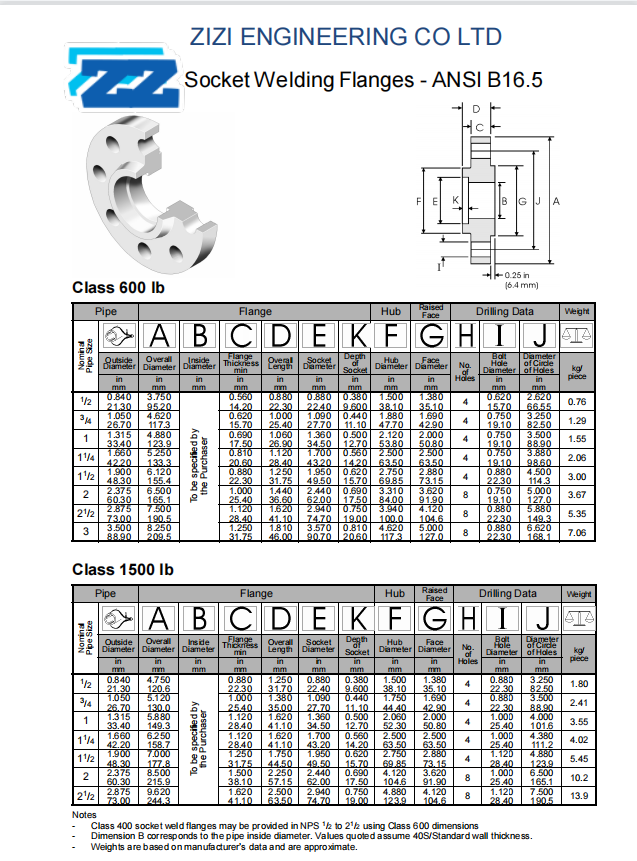

Specification of Forged Steel Flanges

Inquiry

More Forged Steel Flanges