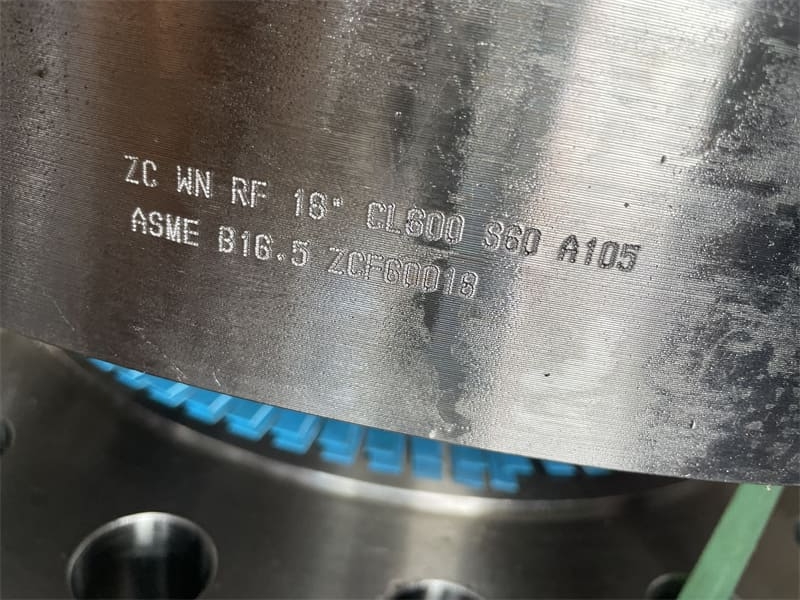

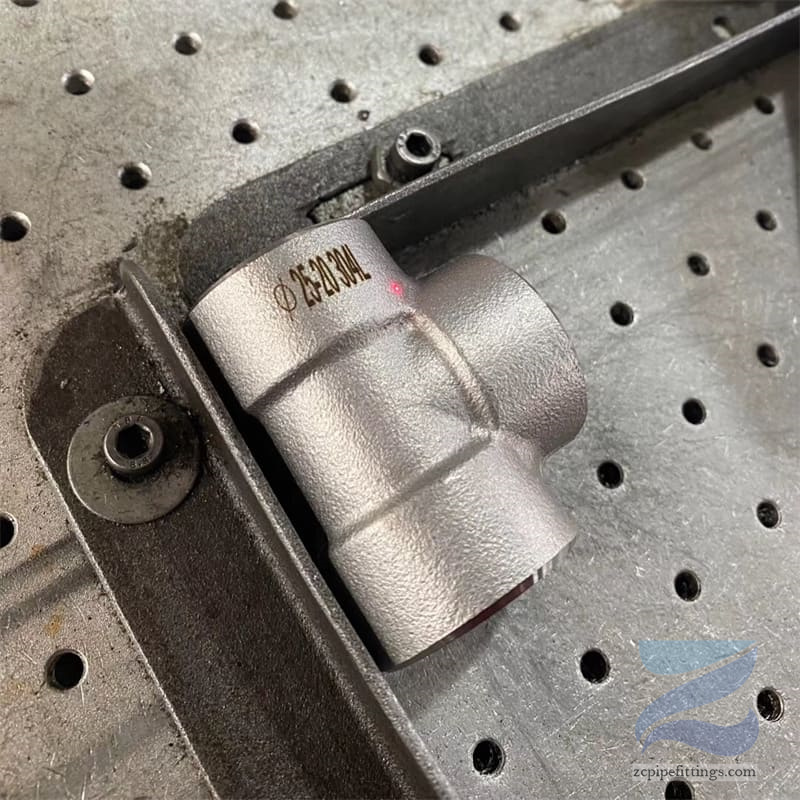

ASTM A105N Carbon Steel Socket Weld Coupling ASME B16.11

What is a Socket Weld Coupling and what about its specification and advantages.

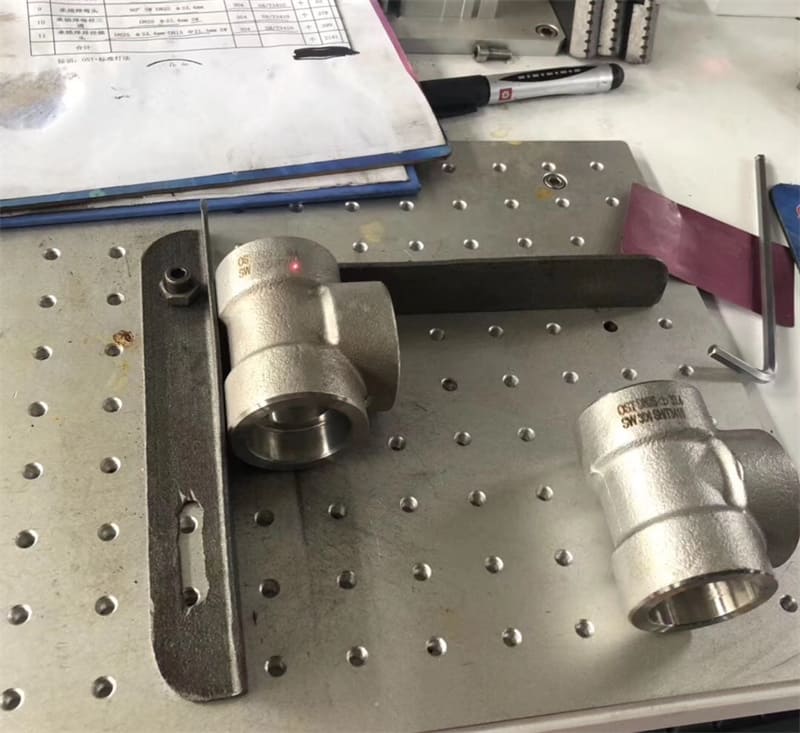

What is a SW Coupling?

A Socket Weld Coupling is used in places where the pipes are fixed permanently. This coupling ensures that the flow of fluids and gases is at the optimum level possible. The Socket Weld Full Coupling is used in connecting pipes with small-bore sizes together. This coupling has a simple construction, and it works without any vibrations or shocks.

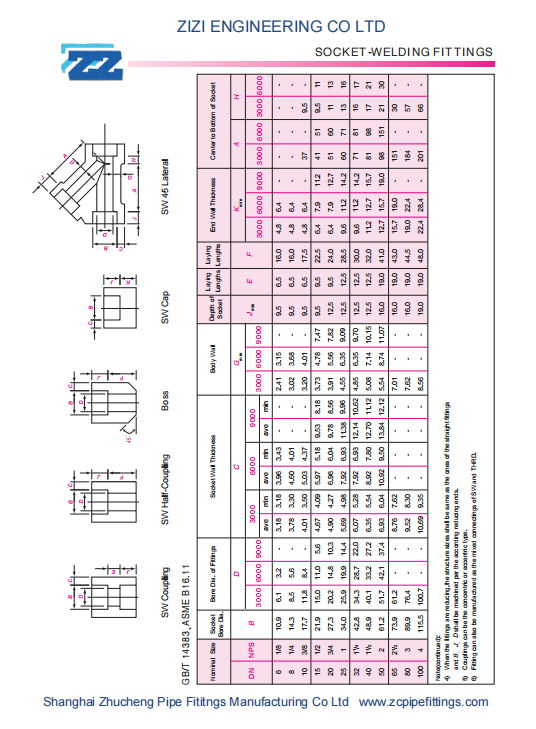

Specification of SW Coupling

| Type | Full and Half coupling |

| Shape | Eaqual and reducing cross |

| Size range | 1/8″-4″/DN6-DN100 |

| Pressure Rating | Class 3000lb 6000lb 9000lb |

| Standard | ASME B 16.11/BS3799 |

| Carbon Steel | ASTM A105/A105N |

| Pipeline Steel | ASTM A694 F42/46/56/60/60 |

| Alloy Steel | ASTM A182 F11/12/5/9/91/92/F22 |

| Stainless Steel | ASTM A182 F304/304L/304H,316/316L,310S,321,317,347,904L |

Advantages of SW Coupling

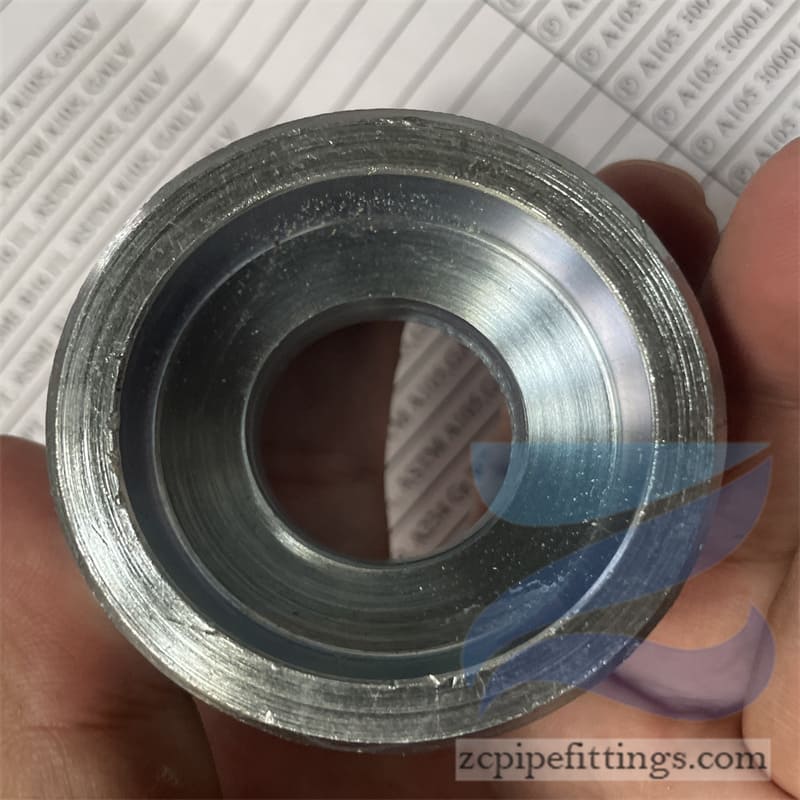

The socket weld pipe fittings can be used in place of threaded fittings,so the risk of leakage is much smaller.

Socket weld pipe need not be beveled for weld preparation.

The weld metal can not penetrate into the bore of the pipe.

Construction costs are lower than with butt-welded joints due to the lack of exacting fit-up requirements and elimination of special machining for butt weld end preparation