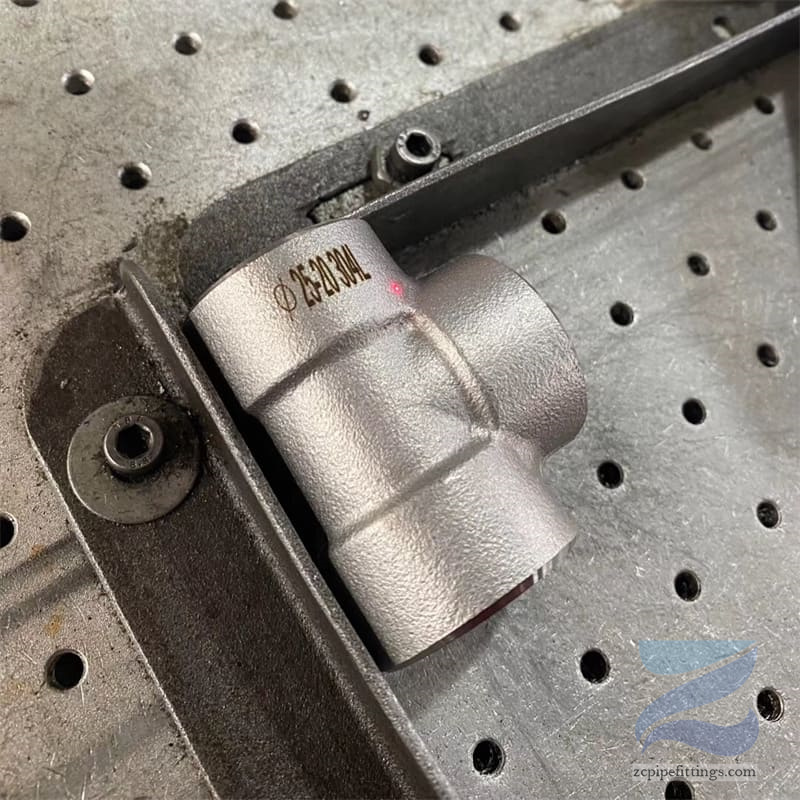

ASTM A105 Threaded Pipe Fittings Elbow

ASTM A105 Threaded Pipe Fittings are used for installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. SA 105 fittings comes in a variety of sizes to fit the pipe they will connect. It is useful to combine, divert or reduce the flow of the water supply.

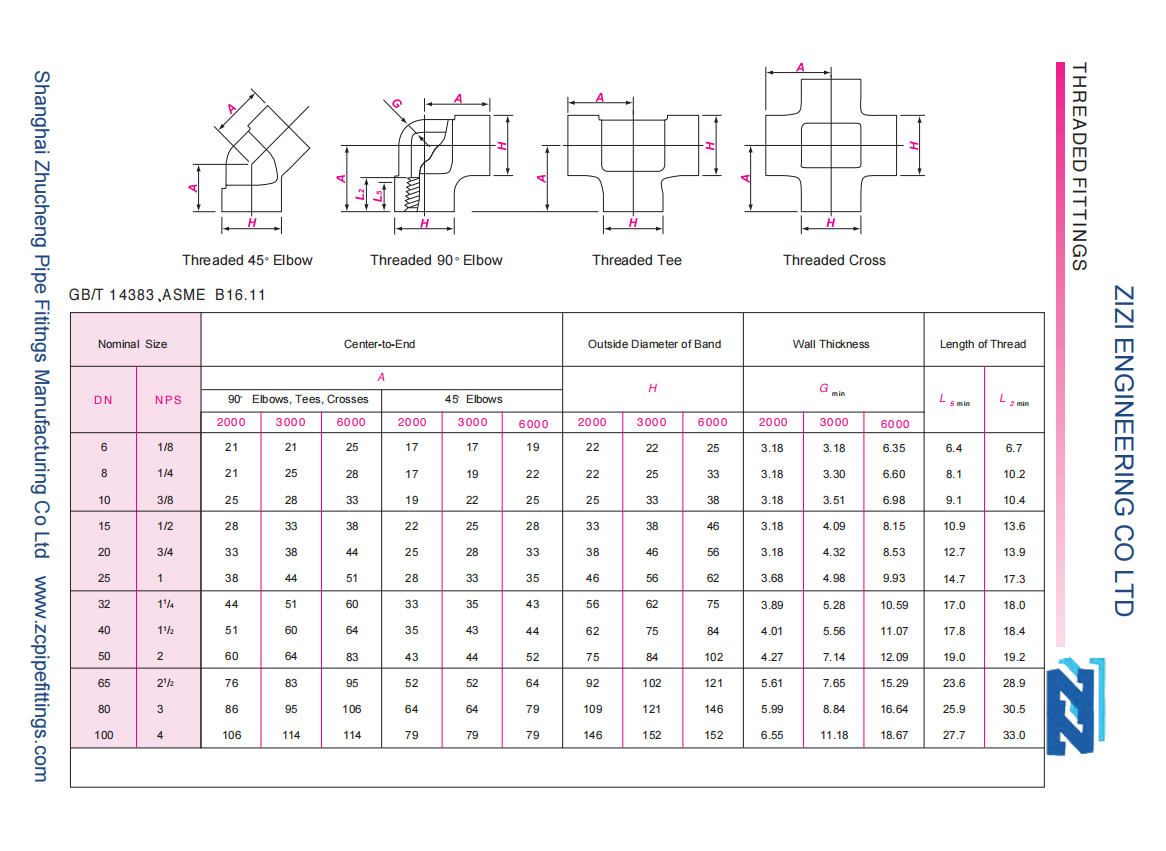

ASME B16.11 is the standard contains ratings, dimensions, tolerances, marking and material requirements for forged fittings, both socket-welding and threaded. Threaded Elbow is available in pressure ratings Class 2000, 3000, and 6000;

Elbow is a pipe fitting that changes the direction of piping. According to the Angle, there are 45° and 90°180° three most commonly used. Elbow material can be divided into carbon steel, alloy steel and stainless-steel.

Steel pipe elbow can be divided into 3 types as buttweld, threaded, socket weld in accordance with connection. The material specification are ASTM A234, A182, A403, A105, A694, A350, A420 and A860.

ASTM A105 Threaded Pipe Fittings are used for installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. SA 105 fittings comes in a variety of sizes to fit the pipe they will connect. It is useful to combine, divert or reduce the flow of the water supply.

ASTM A105 socket weld fittings is a pipe attachment detail in which a pipe is inserted into a break up area of fitting, flange or valve. It is a good choice for high leakage integrity and structural strength are important design consideration.

ASTM A105 Threaded Pipe Fittings are commonly used carbon steel grade which is used to manufacture forge piping components such as forged fittings and flange of small diameter piping, generally for piping whose nominal diameter is NPS 2 or smaller.

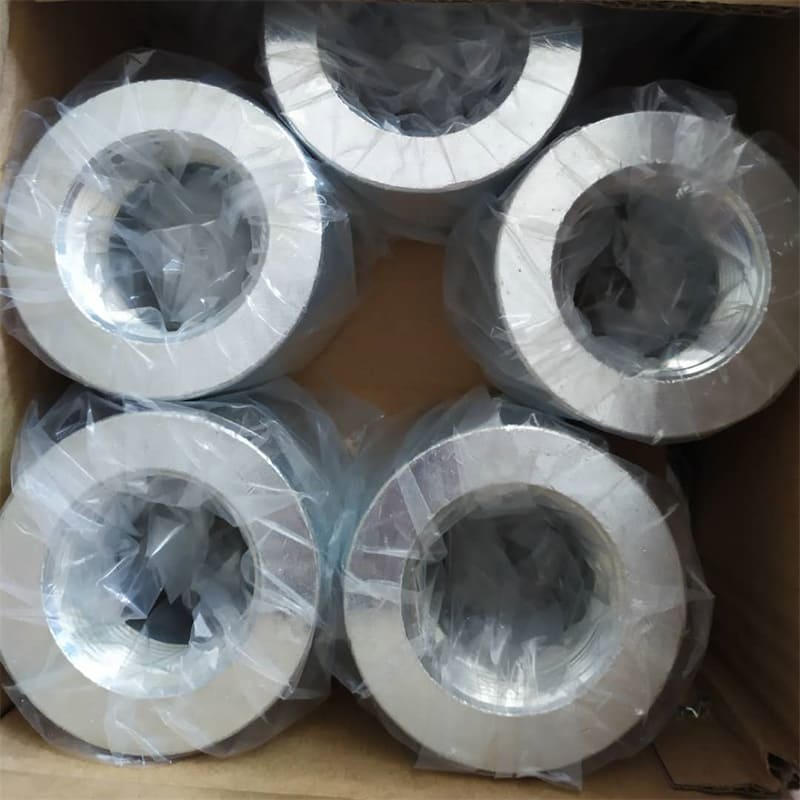

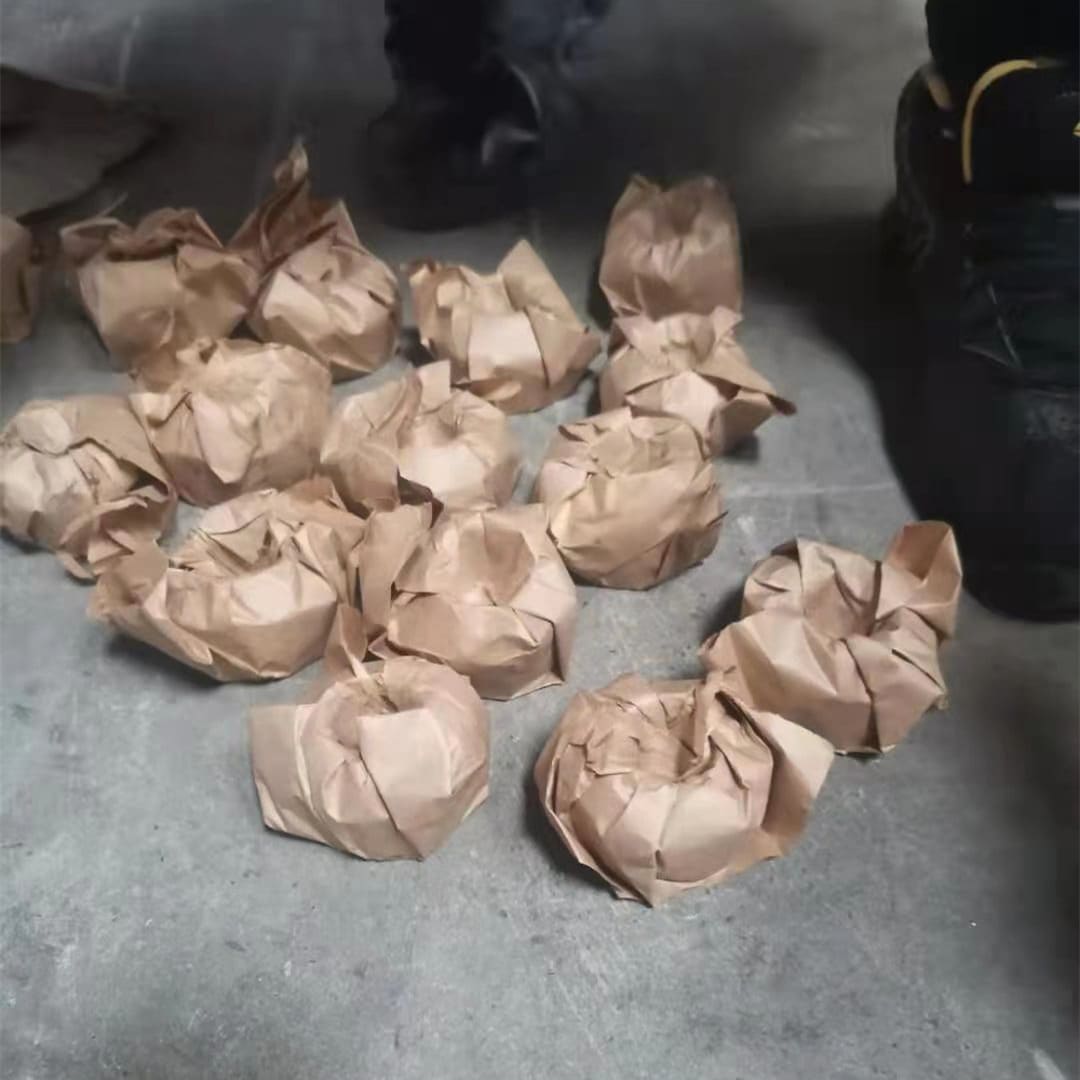

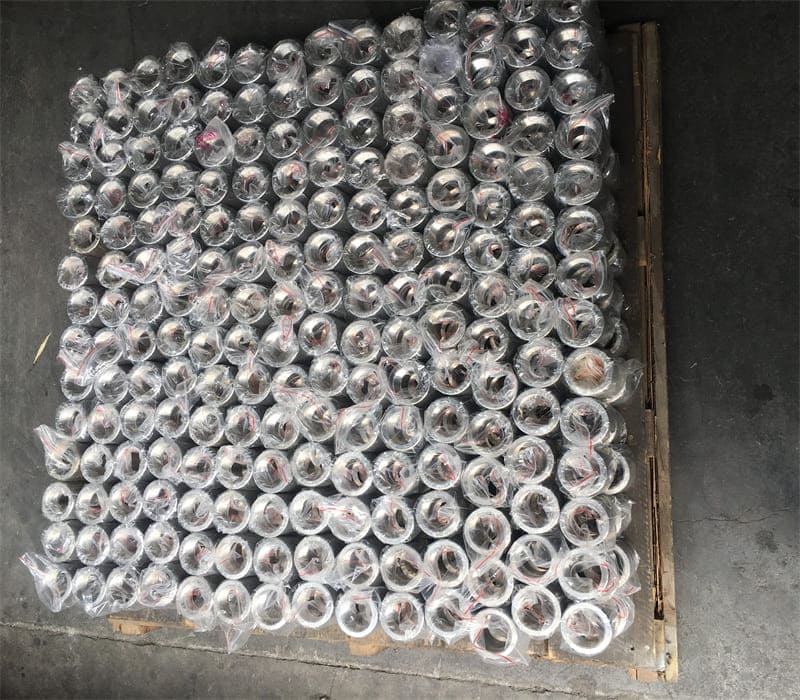

Socket weld fittings & threaded fittings are usually packed in carbon and wooden boxes which large size buttweld fittings are packed in wooden pallets. Shipping marks shall be stick on each package. We will make packing list for each package.

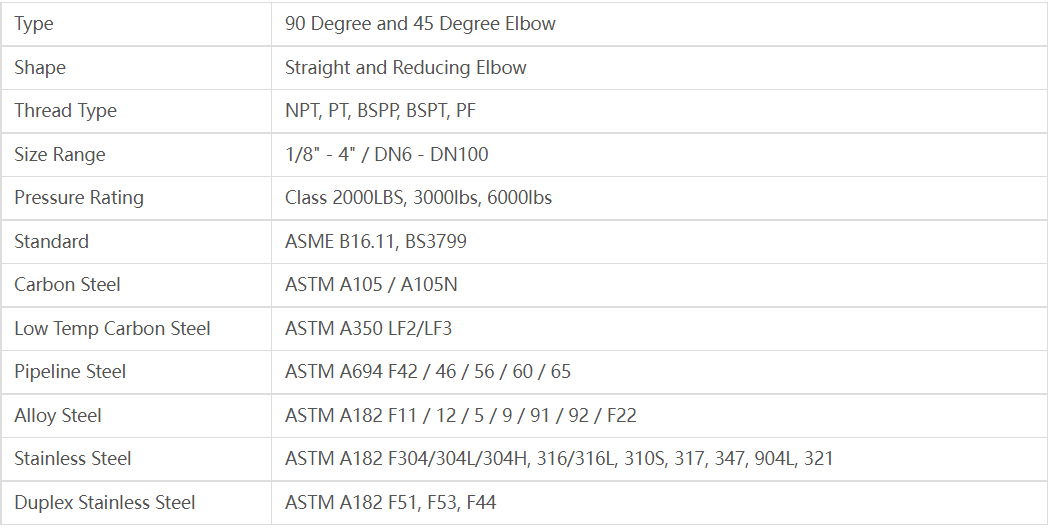

| Threaded Pipe Fittings Specification | |

| Shape | Elbow,Tee, Cross, Coupling, Cap, Swage Nipple, Bushing, Plug, Nipple, Union, Hex Nipple,Threadolet. |

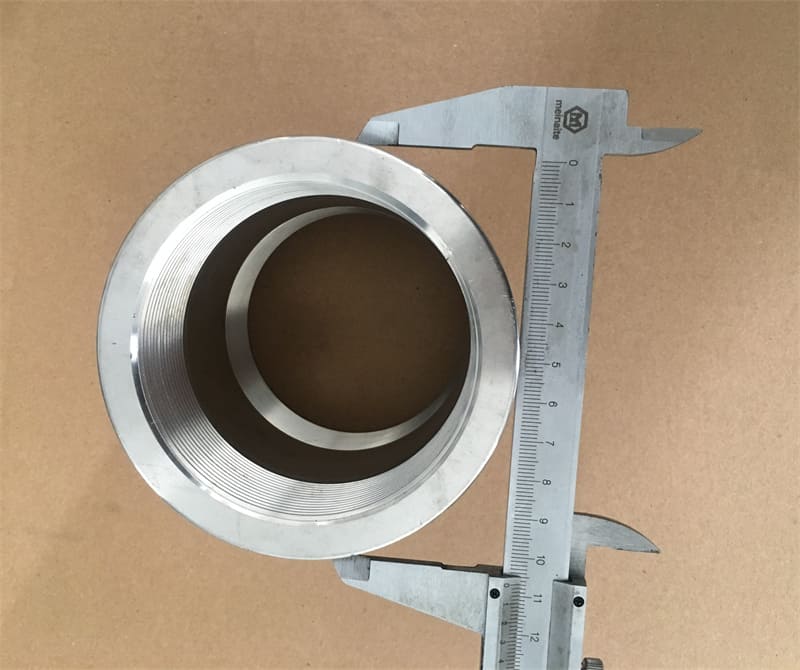

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

ASTM A105 Threaded Pipe Fittings Chemical Composition

–

| Gr. | C | Si | Mn | P | S | Mo | Ni | Cr | Cu | V |

| A105 Forged Fittings | 0.35 | 0.10–0.35 | 0.60–1.05 | 0.035 | 0.040 | 0.12 | 0.40 | 0.30 | 0.40 | 0.08 |

ASTM A105 Threaded Pipe Fittings Mechanical Characteristics

| Gr. | Yield Strength, Min (MPa) | Tensile Strength, Min (MPa) | Elongation, min, % |

| A105 Fitting | 250 | 485 | 30 |

Threaded Elbow Material and Size

Threaded Elbow Dimensions Drawing

Application of ASTM A105 Threaded Pipe Fittings

Oil and Gas

Chemical

Water Pipeline

Noncritical Applications

Power station

Fire Protection