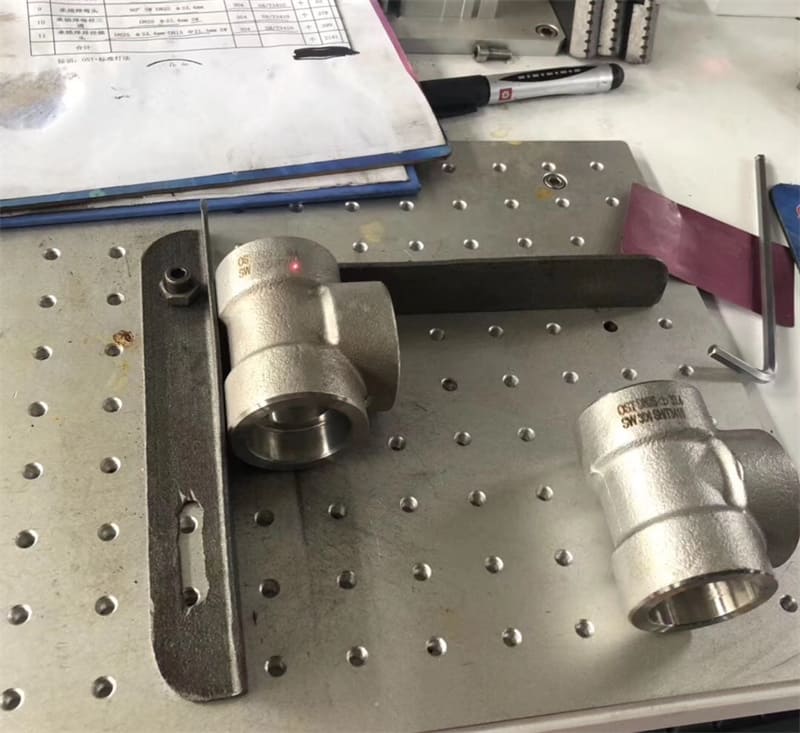

What is a Socket welding elbow?

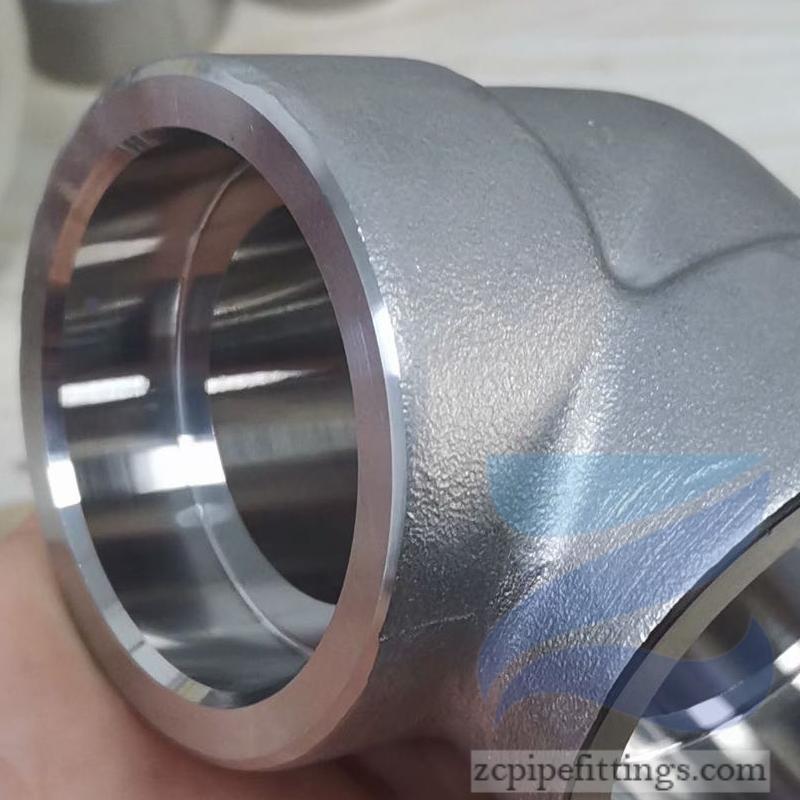

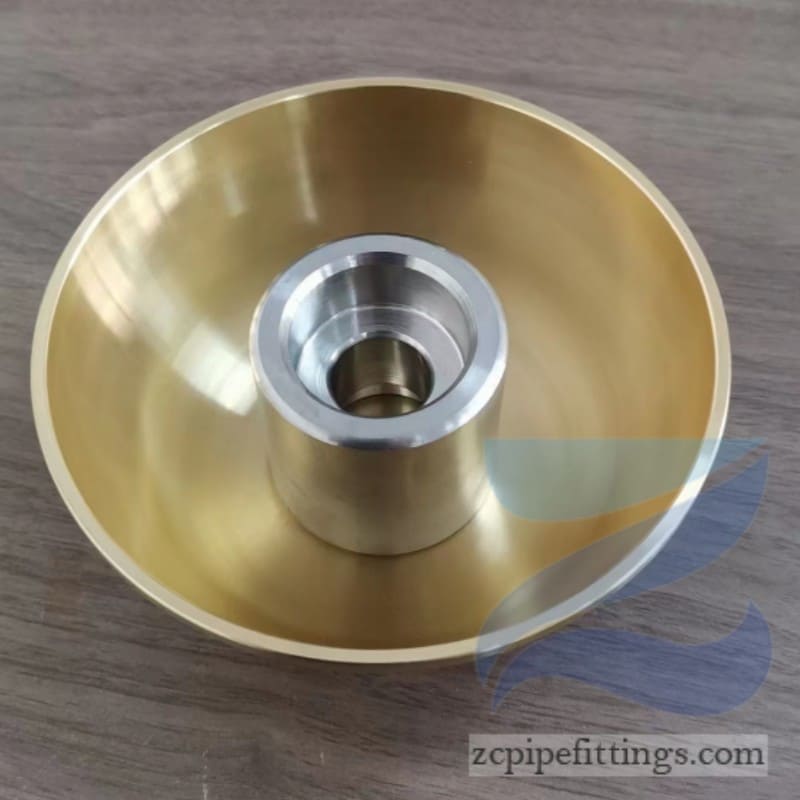

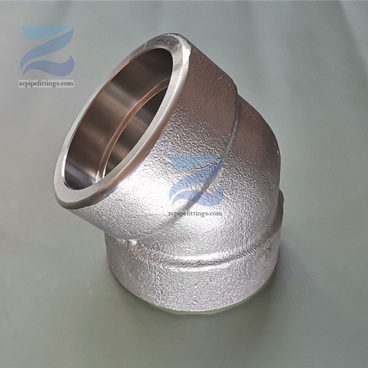

Socket welding (SW) is used for welding pipes and fittings including reducers, tees and elbows. Socket weld pipe fittings are used to permanently join pipes that are inserted into a recess in the fitting, flange or valve. Once correctly inserted, fillet type sealing welds are applied to join the pipe to the fitting.Forged elbows are used to change the direction of the piping system by 45 or 90 degrees. Forged elbows are manufactured according to ASME B16.11 in various material grades, either with socket weld or threaded pipe connections. A special type is the so-called “street elbow”.

SPECIFICATION Of Socket Weld Elbows

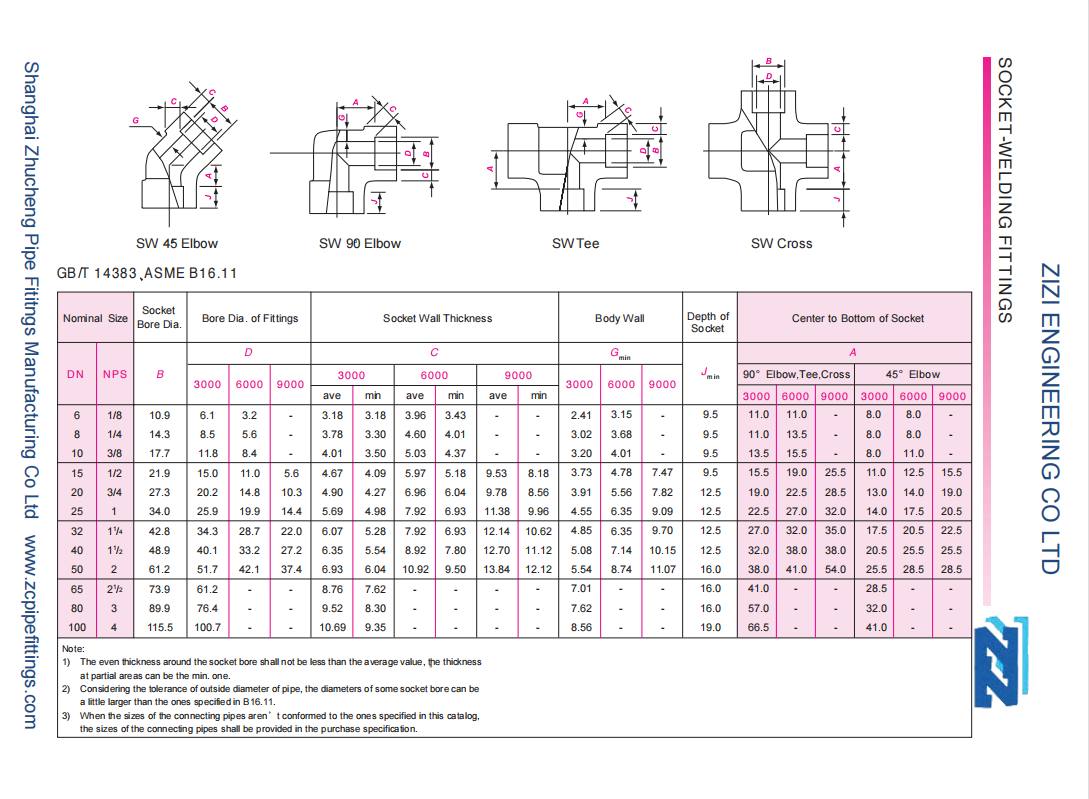

| Type | 90degree and 45degree |

| Shape | straight and reducing |

| Size Range | 1/8″-4″/DN6-DN100 |

| PressureRating | Class 3000lbs/600lbs/9000lbs |

| Standard | GB/T14383,ASME B16.11,BS3799 |

| Crabon Steel | ASTM A105/A105N |

| Low Tem Crabon Steel | ASTM A350 LF2/LF3 |

| Pipeline Steel | ASTM A694 F42/46/50/56/65 |

| Alloy Steel | ASTM A182 F11/12/5/9/91/92/22 |

| Stainless Steel | A182 F304/304L/304H F316/316L F317 F310S F321 F347 F904L |

Advantages And Disadvantages

Advantages of socket weld fittings:

There is no the problem to make the bevel end.

There is no the problem to adjust.

The welding position can be adjusted to flat welding.

Disadvantages of socket weld fittings:

• The welders should ensure that the expansion gap between the socket shoulder and the pipe is 1.6mm.

• Internal cracks and expansion gaps in the socket weld system thought can promote corrosion. It is for this reason that they are considered less suitable for radioactive or corrosive applications