What is Nipple?

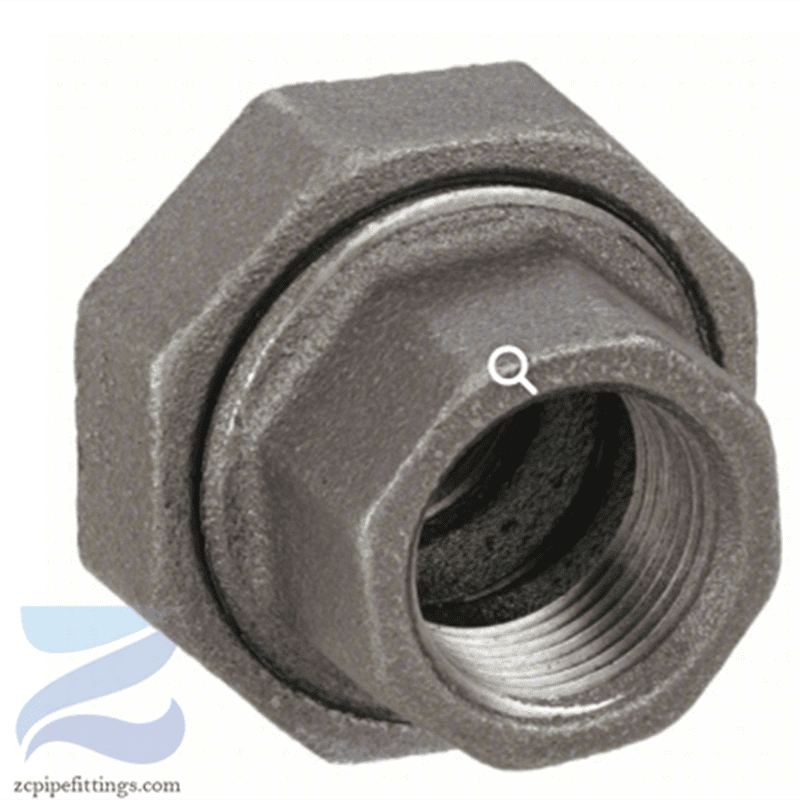

In plumbing and piping, a nipple is a fitting, consisting of a short piece of pipe, usually provided with a male pipe thread at each end, for connecting two other fittings.

The length of the nipple is usually specified by the overall length with thread. It may have a hexagonal section in the center for a wrench to grasp (sometimes referred to as a “hex nipple”), or it may simply be made from a short piece of pipe (sometimes referred to as a “barrel nipple” or “pipe nipple”). A “close nipple” has no unthreaded area; when screwed tightly between two female fittings, very little of the nipple remains exposed. A close nipple can only be unscrewed by gripping one threaded end with a pipe wrench which will damage the threads and necessitate replacing the nipple, or by using a specialty tool known as a nipple wrench (or known as an internal pipe wrench) which grips the inside of the pipe, leaving the threads undamaged. When the ends are of two different sizes it is called a reducer or unequal nipple.

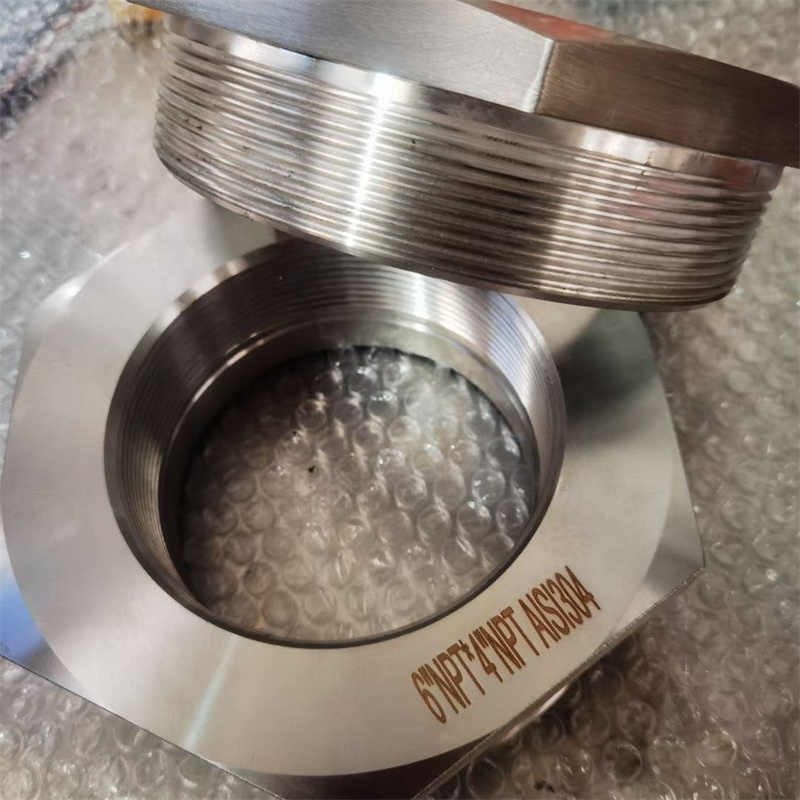

Threads used on nipples are BSP, BSPT, NPT, NPSM and Metric.

Specification of Nipple

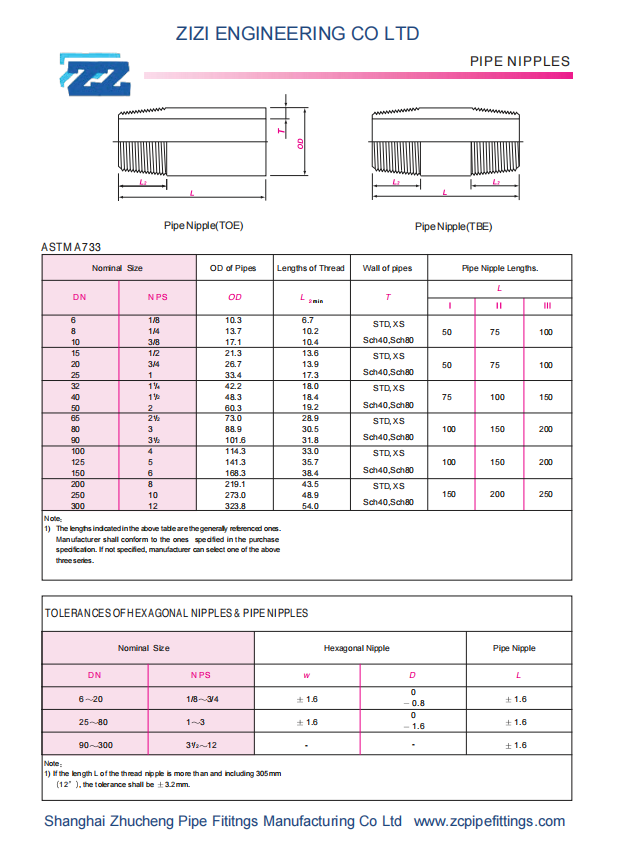

| Shape | Threaded One End (TOE) and Threaded Both End (TBE) |

| Size Range | 1/4” – 12” / DN8 – DN300 |

| Thickness Range | Sch 10 – Sch 160 / XXS |

| Standard | ASTM A733 |

| End Type | Plain (PE), Beveled (BE), Thread (THD) |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Carbon Steel | ASTM A105 / A106B |

| Low Temp Carbon Steel | ASTM A350 LF2/LF3, 16Mn |

| Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

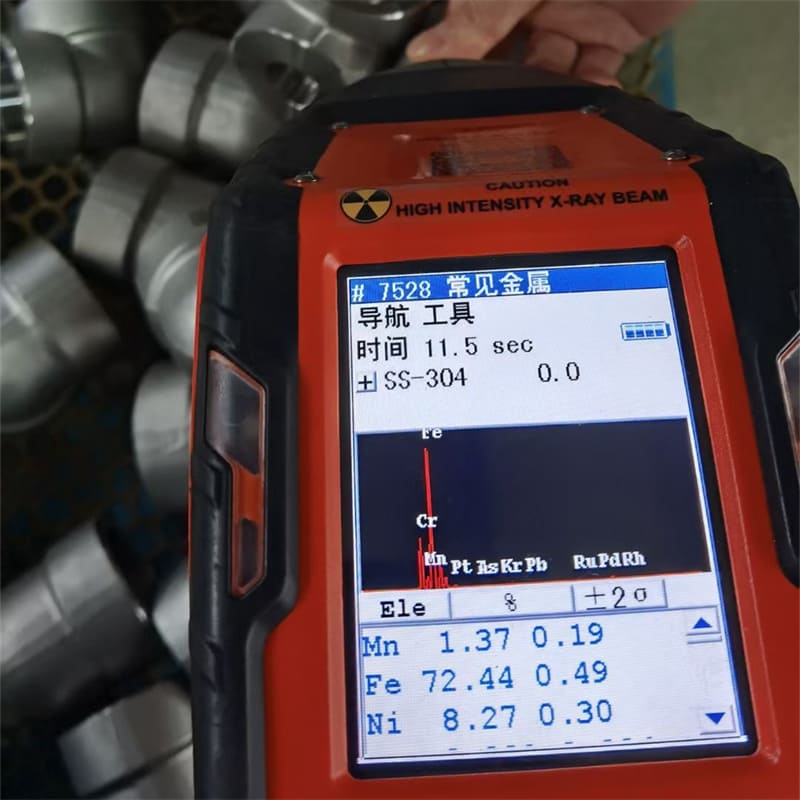

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

Advantage of Nipple

1. The high strength of threaded nipple fitting: According to the principle of cold work hardening of steel, the strength of the straight thread rolled on the steel bar is greatly improved, so that the tensile strength of the straight thread joint is higher than the tensile strength of the steel base material.

2. Stable performance: The joint process is not affected by the quality of workers, so the performance is stable.

3. Fast connection speed: Because methods of prefabricating off-site and assembling on-site are used, the prefabricated rebar can be stored in a large amount of prefabricated steel bar. When the construction period is tight, you only need to add assembly workers at the construction site.

4. Wide range of application: There are basically no restrictions on the range of application, and threaded pipe for sale is more suitable for the field where bending steel bars, fixed steel bars, steel bar cages and other steel bars cannot rotate.