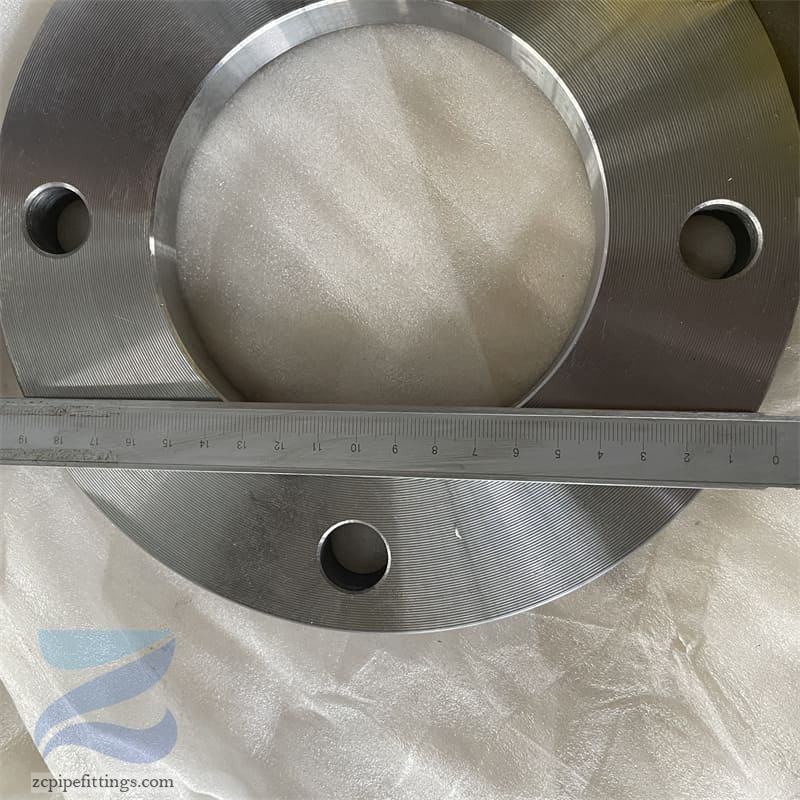

ASTM 182 Stainless Steel Flange Weld Neck(WN) Flange ASME B16.5

What is a Weld Neck(WN) Flange and what about its specification and advantages.

What is a weld neck Flange

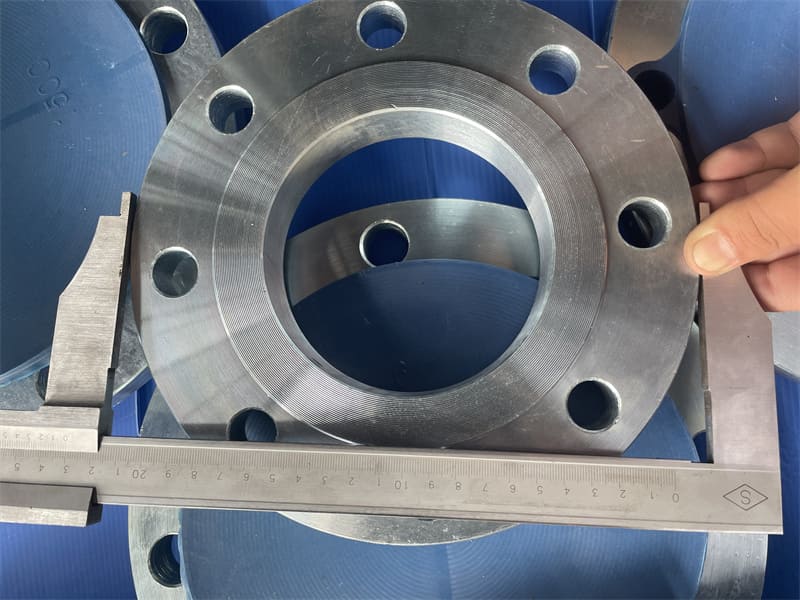

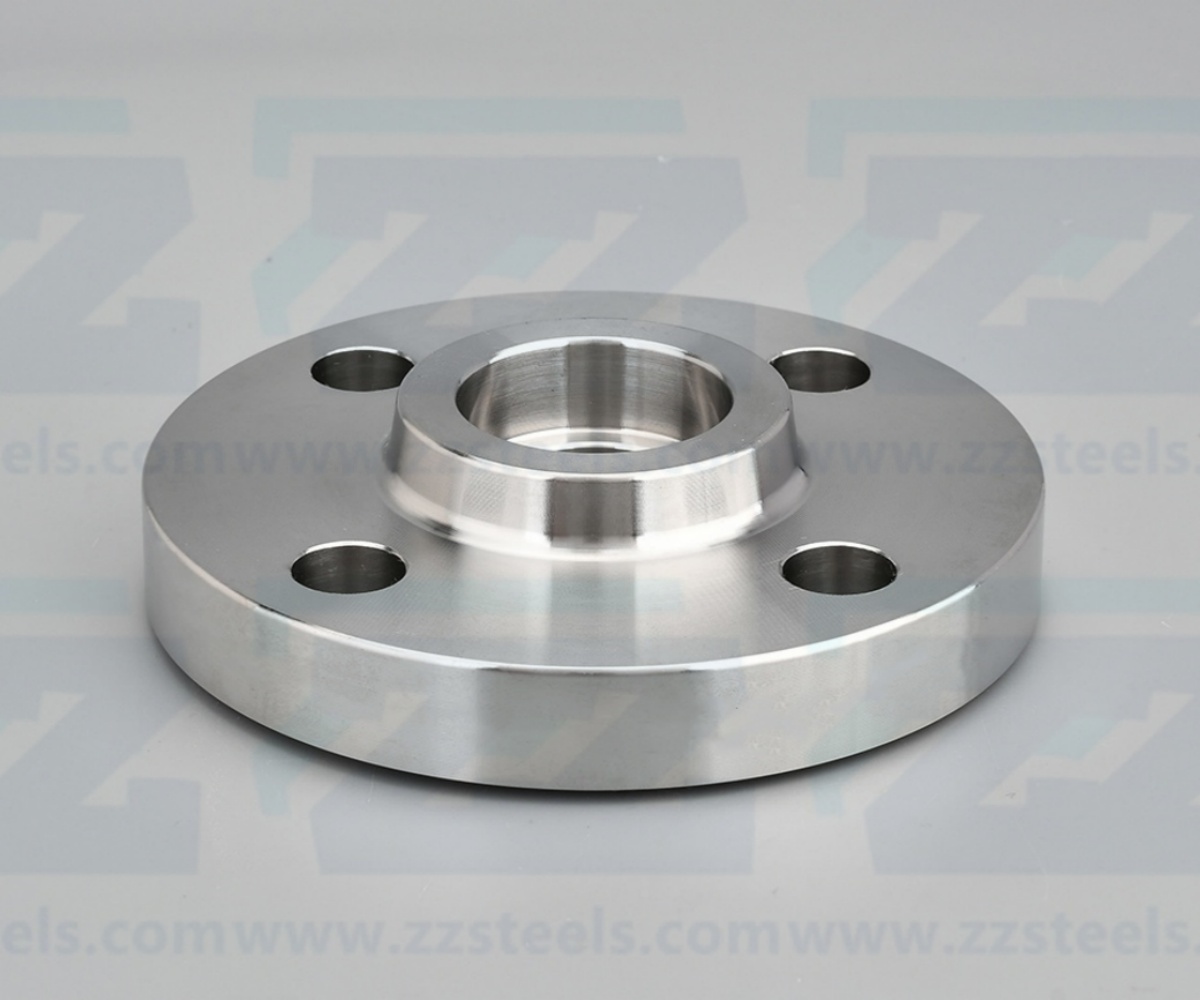

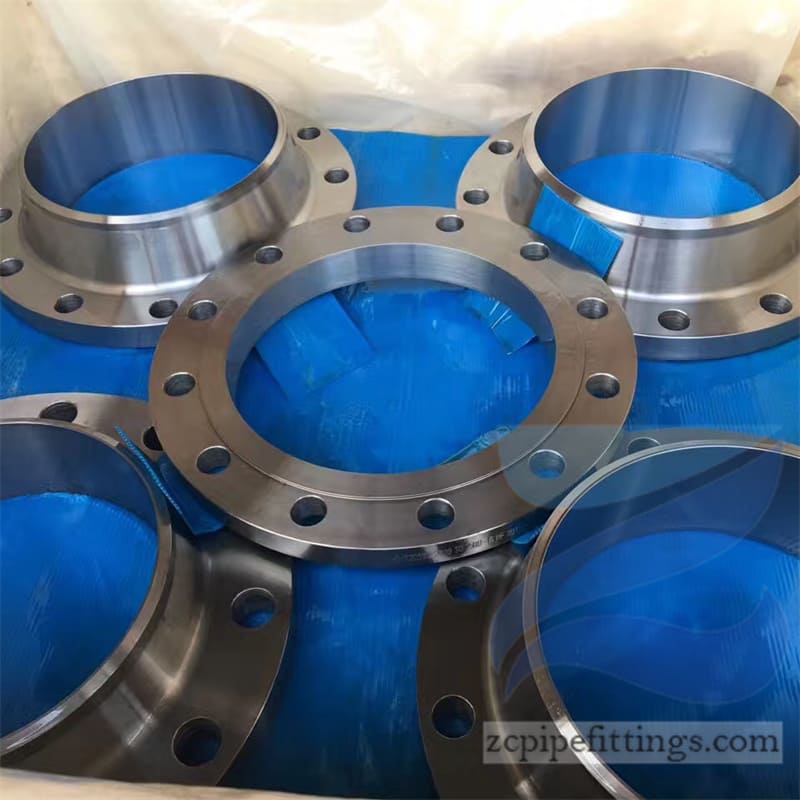

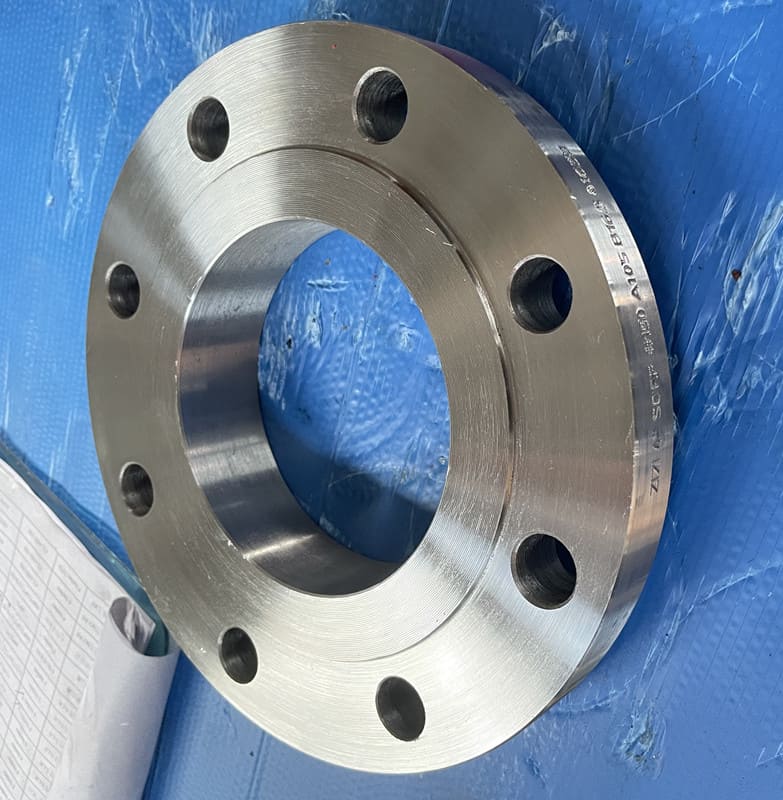

A weld neck flange, also called a tapered hub flange or high-hub flange, is a kind of flange that can relocate stress to the pipes, ensuring a decrease in high-stress concentration at the bottom of the flange. There are two welding neck flanges designs – the first type is used with wipes while the second, longer type cannot be used with pipes but with a process plant. The weld neck flange comprises of a round fitting that extends beyond the rim of the circumference. These flanges, typically manufactured from forging, are actually welded to pipes.

Specification of a forged Flange

| Shape type | Regular and Long Neck |

| Sealing Face | RF,FF,FTJ |

| Size Range | 1/2″-48″/DN15-DN1200 |

| Pressure Rating | Class 150 300 600 900 1500 2500lb |

| Standard | ASME B 16.5,ASME B 16.47 Series A/B |

| Carben Steel | ASTM A150/105N |

| Low Tem Crabon Steel | ASTM A350 LF2/3 |

| Pipeline Steel | ASTM A694 F42/46/56/60/65 |

| Alloy Steel | ASTM A182 F11/12/5/9/91/92 |

| Stainless Steel | ASTM A182 F304/304L/304H,316/316L,310S,317,347,904L |

Advantages of weld neck Flange

Such flanges are suitable for use in hostile environments that have extremes of temperature,pressure or other sources of stress.The resilience of this type of flange is achieved by sharing the environmental stress with the pipe with which it is welded.This type of flange has been used successfully at pressures up to 5,000 psi.The weld neck flange derives its name from the neck portion of the flange that is welded to the end of a piping system.It is designed to transfer stress to the pipe,thereby reducing high stress concentrations at the base of the flange.Weldneck flanges are costlier due to their design and engineering,and increased material.