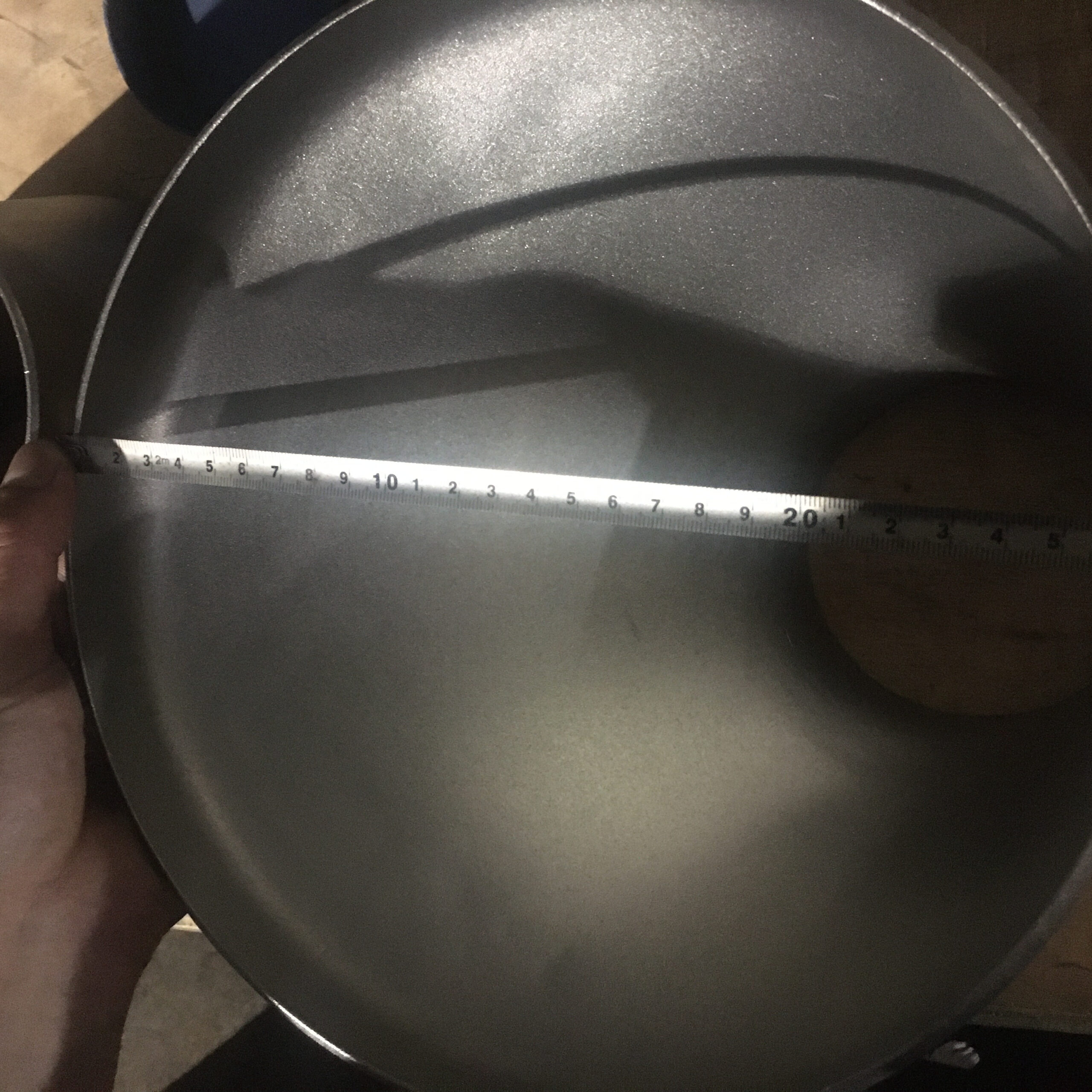

ASMEB16.9 11/2 IN ASTM A53B 4D Bend

Steel pipe bend two pipes into a certain angle and connects them together to change the direction of the pipe. it could be bend directly from a finished pipe with cold bending processes, to different degrees.

ASMEB16.9 is the standard for welded pipe fittings, 11/2 IN ASTM A53B 4D Bend used to change the pipeline direction. 3D and 5D bends are most common use in long pipelines. After that is 6D and 8D bend, as the compensation to complete for small degree change.Steel pipe bending usually required in large diameter in oil and gas pipelines, since it has better capacity to transport the material, and long pipelines will need different radius of pipe bends to be installed in complex conditions.

| Shape | Elbow, Tee, Cross, Bend, Reducer, Cap, Stub End |

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Product features

- Since there is no irregular surface inside the pipe and the fluid does not have to change direction suddenly, the flow of bend is usually smoother.

- They can be almost any bending radius and angle.

- Pipe bends are commonly produced on site to meet a specific need by hot induction bending or cold bending.

Pipe Bend VS Elbow

- Bending Radius of Bend and Elbow

Bending Radius of Bend and Elbow

Steel pipe bend radius: Above 2 times of D, so there are 2D, 2.5D, 3D, 5D, 6D, 7D or 8D pipe bend.

Steel pipe elbow radius: R=1D or R=1.5D or 2D. Below 1.5D is short radius elbow, and more than 1.5D but not over 2D is long radius elbow.

- Different of manufacturing processes

Bend: Could be bend directly from a finished pipe with cold bending processes, to different degrees.

Elbow: Shall be made according by standard manufacture procedures, with hot finishing or hot bending, to a certain degree, 45°, 90° or 180°.

Applications

- Automotive

- industry

- medical equipment,

- solar panel frame

- industrial equipment and wires