ASME B16.9 Steel Pipe Cross Fittings

ASME B16.9 cross is a pipe fitting used to connect four pipes together, and the connection is achieved by welding. It plays a role in diversion or confluence in the pipeline system and is an important connector in the pipeline layout.

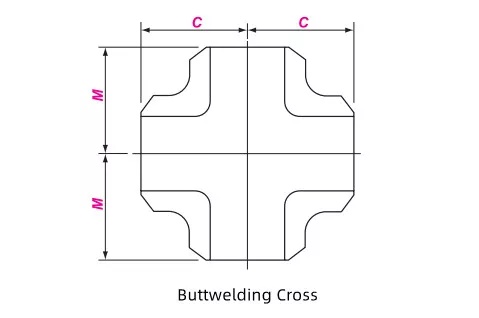

ASME B16.9 butt-weld cross is a pipe fitting used to connect four pipes together, and the connection is achieved by welding. It plays a role in diversion or confluence in the pipeline system and is an important connector in the pipeline layout.

A butt-weld cross usually has four interfaces, and the size and specifications of these interfaces are determined according to different pipeline requirements. The internal channel is designed reasonably to ensure that the fluid can flow smoothly in the cross and reduce pressure loss. For example, in some industrial pipeline systems, the interfaces of the butt-weld cross may be precisely processed according to the outer diameter of the pipeline, and the interfaces will be specially treated to facilitate welding operations.