ASME B16.9 Butt Weld Eccentric Reducer

The butt welded eccentric reducer is a pipe fitting used to connect pipes of different diameters, and its central axes do not overlap, and there is an eccentricity.

The butt welded eccentric reducer is a pipe fitting used to connect pipes of different diameters, and its central axes do not overlap, and there is an eccentricity. It plays the role of changing the diameter and flow direction in the pipeline system, and is usually used in places where the pipe diameter needs to be adjusted and adapted to different installation spaces or process requirements.

It consists of a large end and a small end. The large end is connected to the pipe with a larger diameter, and the small end is connected to the pipe with a smaller diameter. In terms of manufacturing technology, it is generally formed by forging or stamping, and then the two ends are processed by butt welding to ensure the sealing and firmness of the connection with the pipeline.

Specification of Eccentric Reducer

| Size Range | 3/4″ – 60″ / DN20 – 1500 |

| Thickness Schedule | SCH 10 – SCH 80, SCH 160, XXS |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Germany Standard | DIN2605/2615/2616/2617 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,

15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Dual Phase Stainless Steel | A815 WPS32205/32750/31803/32760 |

Butt Weld Reducer Weight Chart

The weight chart is available in concentric and eccentric reducer which based on the ASME / ANSI B16.9 . The weight for the size more than DN1200 (NPS 48) is calculated on the basis of thickness 9.53mm.

| Nominal Size | SCH20 | STD | SCH40 | SCH80 | SCH120 | SCH160 | |

| DN | NPS | ||||||

| 15 | 1/2 | 0.08 | 0.08 | 0.1 | |||

| 20 | 3/4 | 0.17 | 0.17 | 0.2 | |||

| 25 | 1 | 0.21 | 0.21 | 0.25 | 0.22 | ||

| 32 | 1 1/4 | 0.29 | 0.29 | 0.35 | |||

| 40 | 1 1/2 | 0.42 | 0.42 | 0.58 | 0.6 | ||

| 50 | 2 | 0.8 | 0.8 | 1.03 | 1.04 | ||

| 65 | 2 1/2 | 1.05 | 1.05 | 1.42 | 1.65 | ||

| 80 | 3 | 1.36 | 1.36 | 1.9 | |||

| 90 | 3 1/2 | 1.63 | 1.63 | 2.27 | 2.4 | ||

| 100 | 4 | 2.77 | 2.77 | 3.93 | 4.4 | ||

| 125 | 5 | 3.96 | 3.96 | 6 | 7.14 | ||

| 150 | 6 | 6.31 | 6.31 | 9.26 | 10.8 | ||

| 200 | 8 | 7.85 | 10.7 | 10.7 | 17.5 | 15 | 18.4 |

| 250 | 10 | 11.2 | 15.8 | 16.3 | 25.1 | 25.1 | 32.5 |

| 300 | 12 | 25.6 | 28.8 | 32.1 | 56.5 | 41.7 | 53.3 |

| 350 | 14 | 30.5 | 38.5 | 48.8 | 79 | 84.5 | 106 |

| 400 | 16 | 35.2 | 44.5 | 64.3 | 102 | 112 | 143 |

| 450 | 18 | 62.7 | 62.7 | 98.5 | 165 | ||

| 500 | 20 | 72.6 | 72.6 | 181 | |||

| 550 | 22 | 97 | 79.1 | 142 | 226 | ||

| 600 | 24 | 130 | 100 | ||||

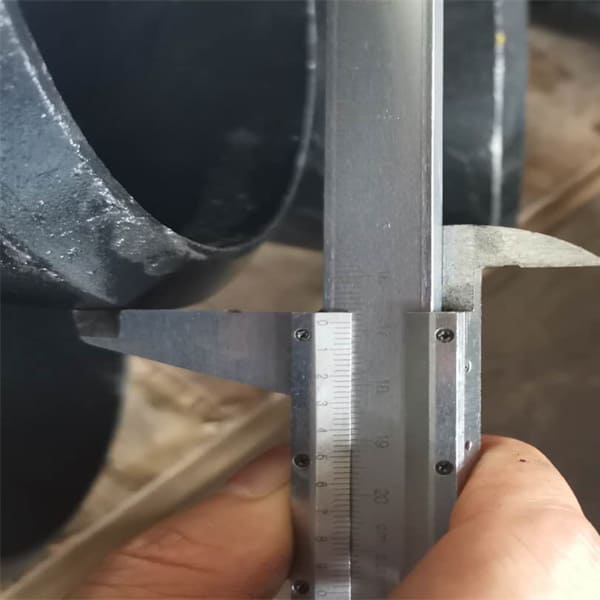

How to inspect the Eccentric Reducer

We are very strict in the inspection of reducers. First, we check whether there are defects such as cracks and heavy skin on the appearance. These defects may affect its strength and sealing performance. Then, according to the provisions of the standard ASME B16.9, we check whether the dimensions of the eccentric reducer meet the requirements, including the large end diameter, small end diameter, wall thickness, etc. In addition, we also measure the tensile strength and yield strength of the eccentric reducer through tensile tests to verify whether its strength meets the standard requirements.