ASME B16.9 3” SCH80 A420 WPL6 Steel Pipe Elbow

90 degree steel pipe elbow functioned to change fluid direction by 90 degree, so also named as vertical elbow. A 90 degree elbow attaches readily to plastic, copper, cast iron, steel and lead. It can also attach to rubber with stainless steel clamps. Available in many materials like silicon, rubber compounds, galvanized steel etc.

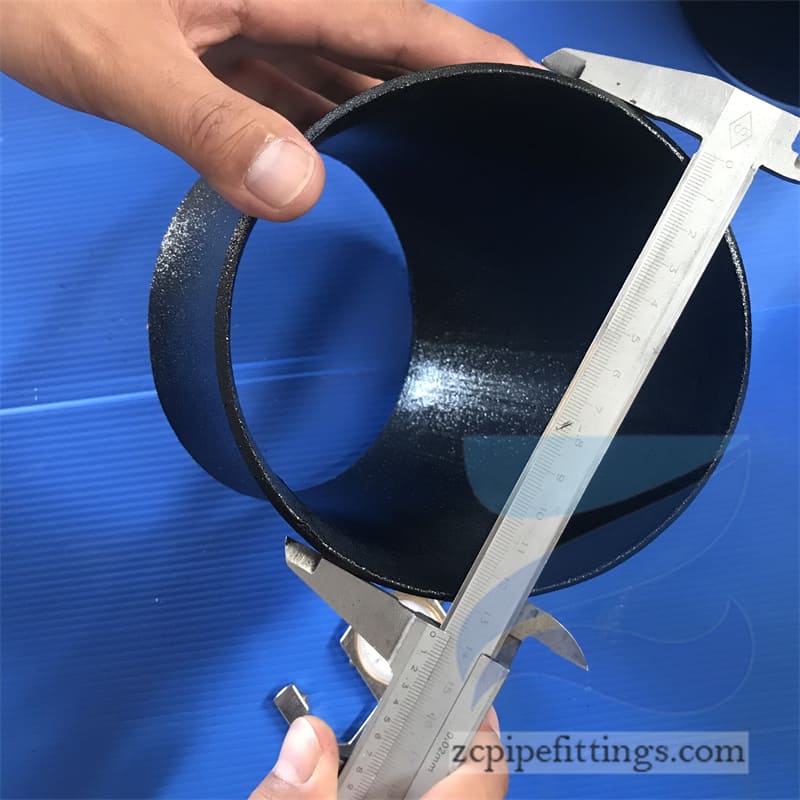

ASME B16.9 3” SCH80 steel pipe elbows are installed between different lengths of pipe or tubing. A420 WPL6 Steel Pipe Elbow helps to change direction at 90 degrees and is commonly used to connect hoses to pumps, deck drains and valves. One of the most common ways to produce elbows is to bend straight steel pipes with a hot mandrel. After the steel pipe is heated at high temperature, it is pushed, expanded and bent step by step by the inner tool of the mandrel. Using hot mandrel bending, can produce a wide range of size of seamless elbow. The bending characteristics of the mandrel largely depend on the overall shape and size of the mandrel. Compared with other bending methods, the hot bending head has the advantages of small thickness deviation and large bending radius. At the same time, the use of bending instead of prefabricated bending greatly reduces the amount of welding required. This reduces the amount of work required and increases the quality and availability of the pipeline. Cold bending is the process of bending straight steel tubes at room temperature in a pipe bender. Cold bending is suitable for pipes with outer diameter of 17.0 ~ 219.1 mm and wall thickness of 2.0 ~ 28.0 mm. The recommended bending radius is 2.5 x Do. The bending radius is usually 40D. By cold bending, we can get small radius bends, but we need to wrap the interior with sand to prevent wrinkles. Cold bending is a quick and inexpensive method of bending. This is a competitive option for manufacturing pipes and machine parts.

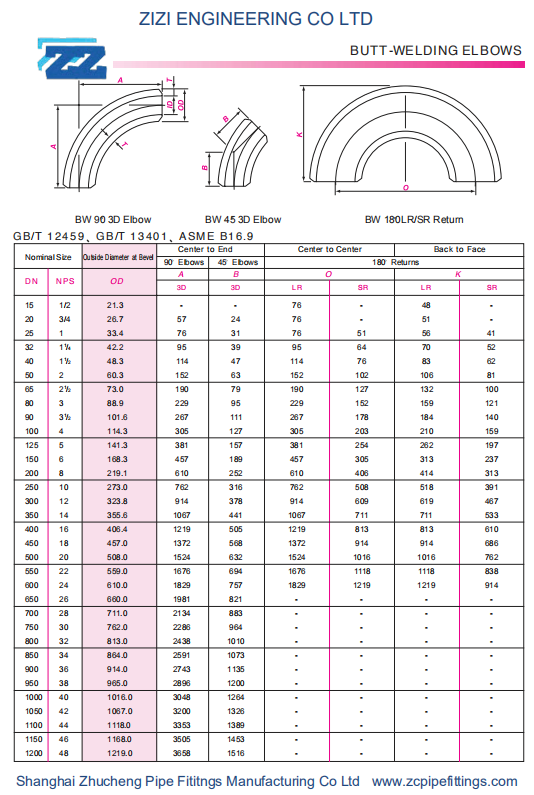

| Shape | Elbow, Tee, Cross, Bend, Reducer, Cap, Stub End |

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

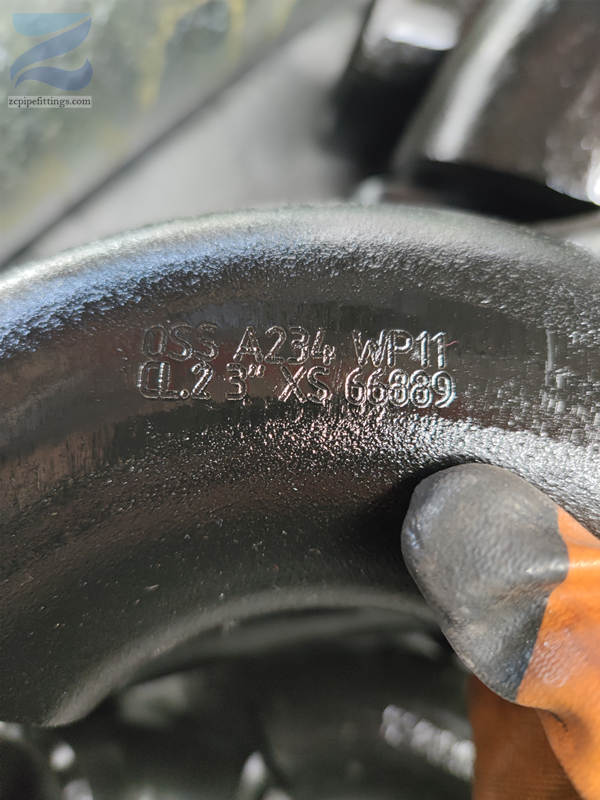

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Product description

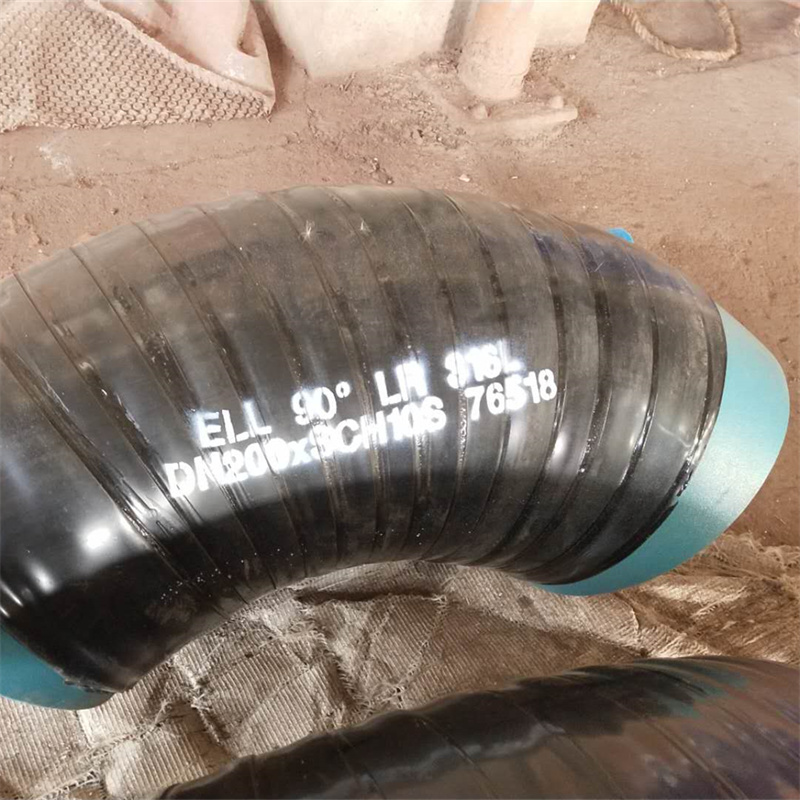

BW 90 degree ELBOW

BW 90 degree elbow is formed by hot forming and connects steel pipes or other pipe fittings through butt welding process. Its function is to change the direction of the fluid by 90 degrees, so it is also called vertical elbow.

Long radius ELBOW

Long radius elbow refers to the pipe outer diameter with radius of curvature equal to 1.5 times, i.e R = 1.5D.

Short radius ELBOW

Short radius elbow means that its radius of curvature is equal to the outer diameter of the tube, i.e R = 1.0D

Product features

- ReliableLightweight

- High tensile strength

- Weldability

- Excellent corrosion resistance

- Resistance to oxidation

Petroleum

Chemical

Power

Gas

Metallurgy

shipbuilding