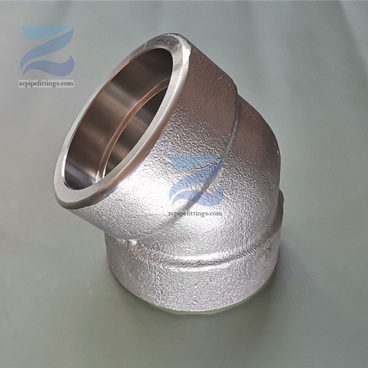

ASME B16.11 Socket Pipe Fittings

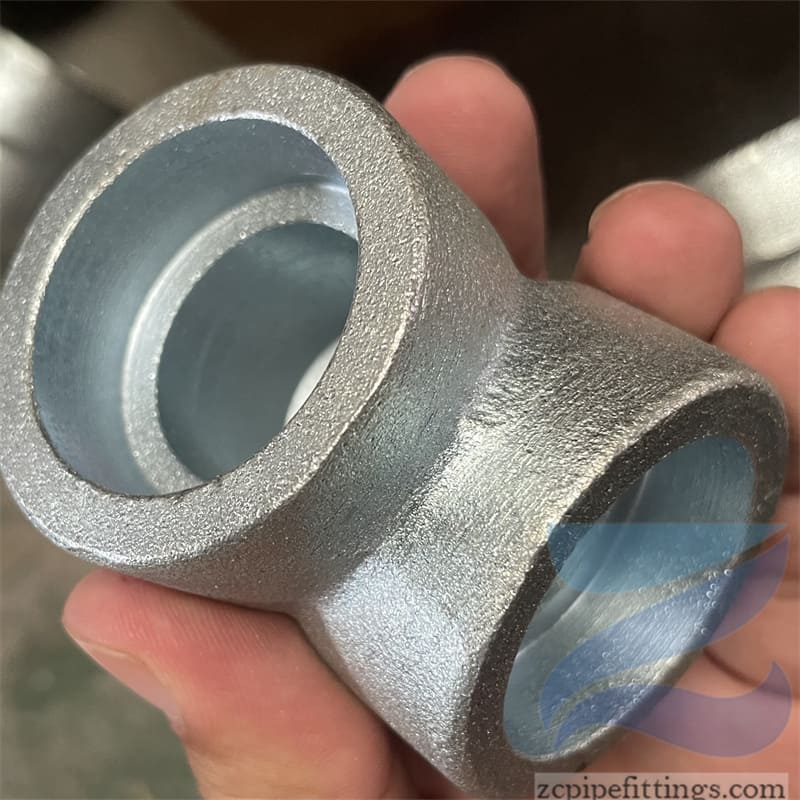

socket pipe fittings are a commonly used type of pipe fittings. The main feature is the socket structure.It consists of a socket and a spigot.

socket pipe fittings are a commonly used type of pipe fittings. The main feature is the socket structure. It consists of a socket and a spigot. The spigot end is inserted into the socket end, and a sealing connection is achieved through sealing materials. This structure is relatively convenient when installing pipelines and does not require complex welding equipment. It is especially suitable for some occasions where welding is not convenient or where the flexibility of pipeline connection is required to be high.

socket fittings are widely used in pipeline systems in petroleum, chemical, natural gas and other industrial fields to transport various media. Due to its excellent corrosion resistance and high temperature resistance, socket fittings are also suitable for pipeline systems in food, pharmaceutical, shipbuilding and other industries.

Specification of Socket Pipe Fittings

| Size: | 1/4″ to 4″ ( DN6 to DN100) |

| Pressure Rating: | Class 3000, 6000, 9000 LBS |

| Standard: | ASME 16.11 – Socket Welding and Threaded Forged Fittings MSS SP-79 – Socket Welding Reducer Inserts MSS SP-83 – Socket Weld Union MSS SP-95 – Swage(d) Nipples and Bull Plugs BS 3799 – Specification for Steel Pipe Fittings |

| Type: | socket weld elbow, tee, cross, cap, coupling, boss, lateral, reducer insert and union. |

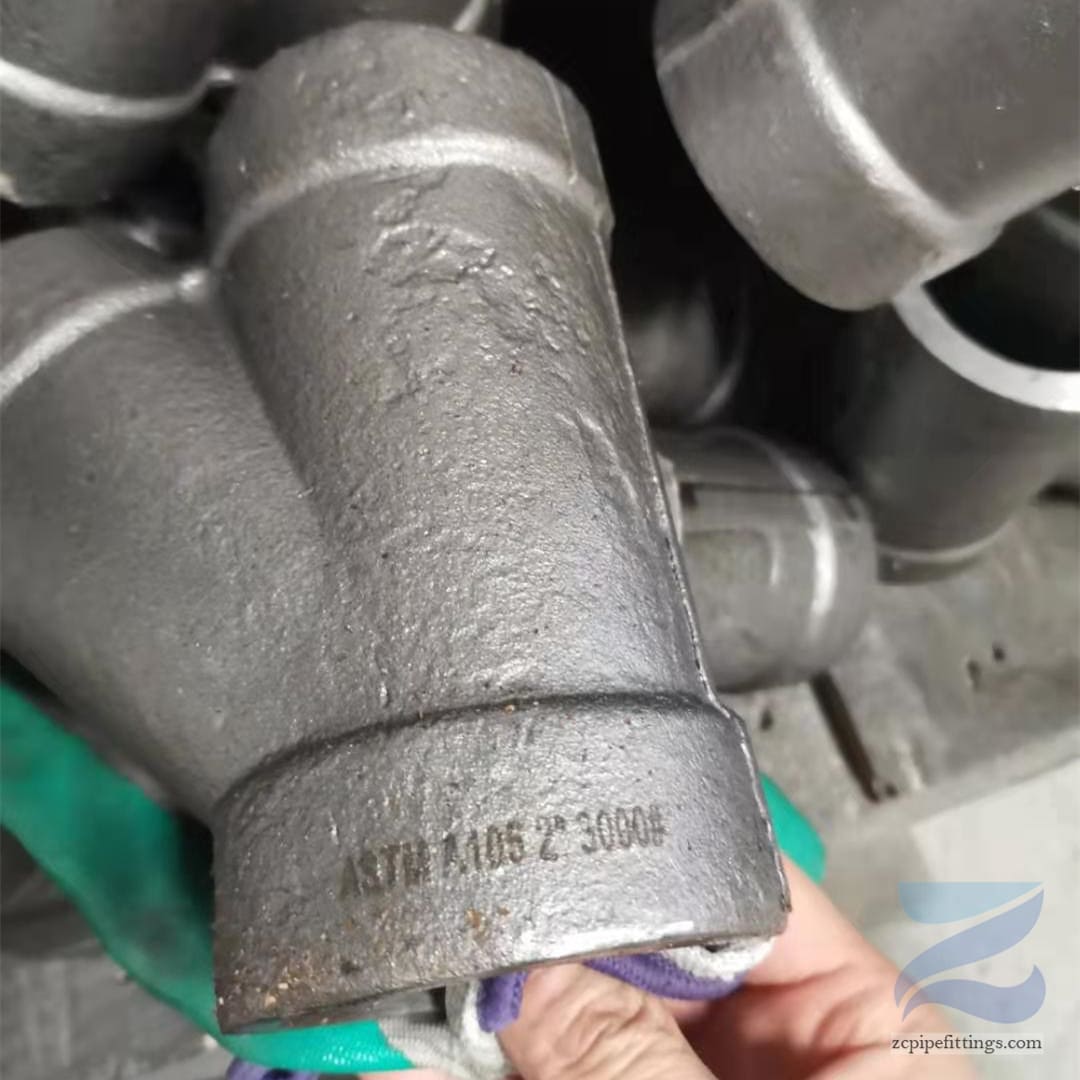

| Material: | ASTM A105, A350 LF2/LF3, A182 F5, F9, F11, F12, F22, F91, F304/304L, F316/316L, F317, F310S, F321, F347, F904. |

Materials of Carbon Steel Socket Pipe Fittings

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

Mechnical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

Inspection of A105 Socket Pipe Fittings

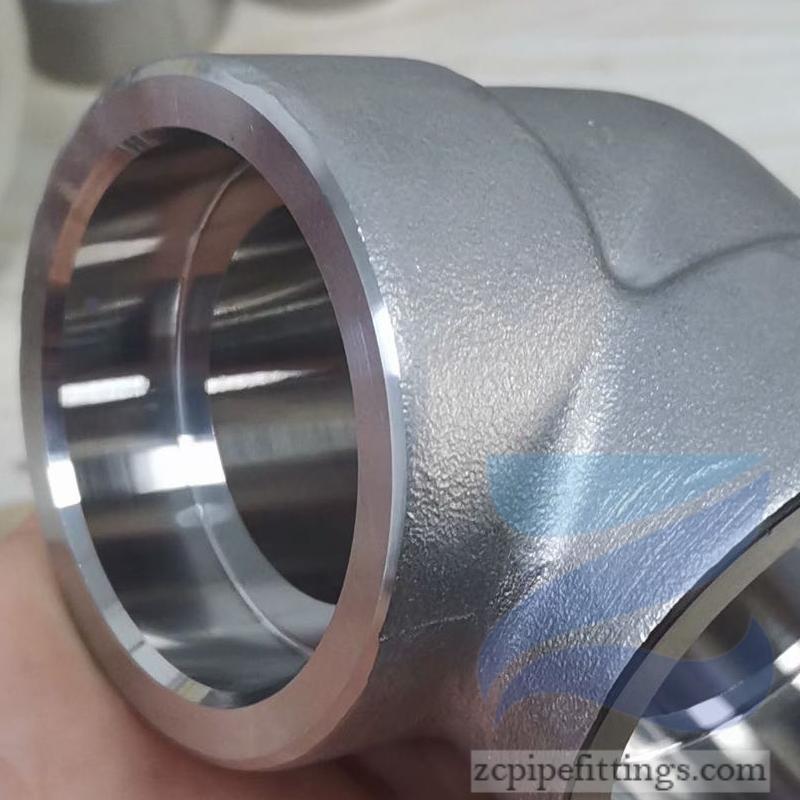

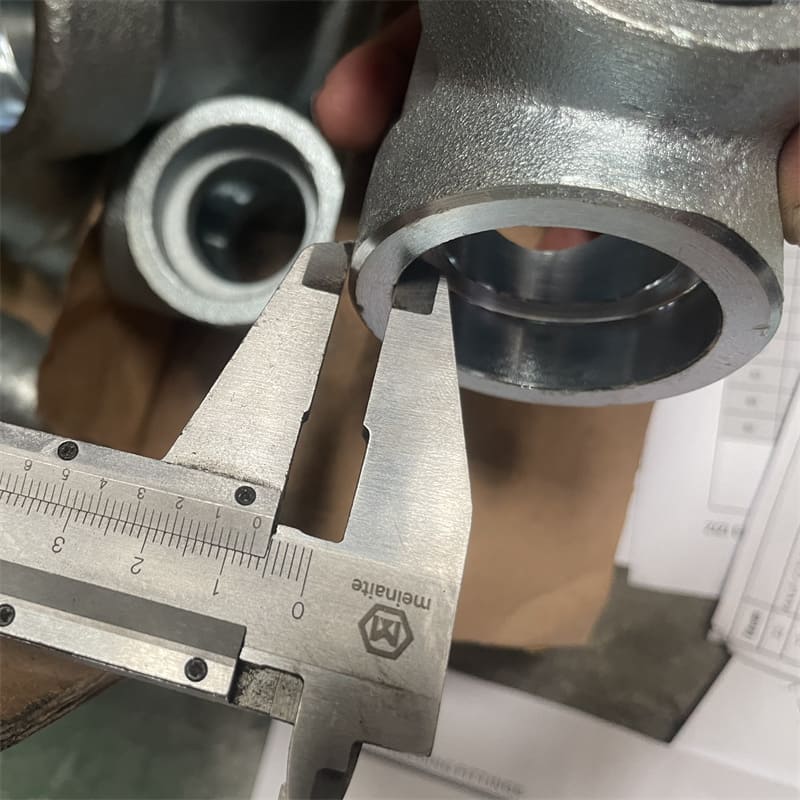

The inspection of A105 socket pipe fittings has different inspection standards according to different types. First of all, the dimensions such as the depth of the socket and the length of the spigot must meet the relevant standards. Measure the outer diameter, inner diameter and other dimensions of the fittings, and their deviations should be within the allowable range. If it is a pipe fitting with angle requirements such as elbows and tees, the angle deviation must meet the standard. For socket and spigot fittings with a small nominal diameter (such as below DN50), the inner diameter deviation may be controlled at around ±0.5mm; while for fittings with a larger nominal diameter (such as DN200 and above), due to the relatively large cumulative effect of manufacturing and installation tolerances, the inner diameter deviation may be allowed to be within ±1.5mm.

The chemical composition of carbon steel is tested to ensure that the content of elements such as carbon, silicon, manganese, sulfur, and phosphorus meets the corresponding standards. For example, excessive sulfur and phosphorus content will reduce the toughness and weldability of carbon steel.