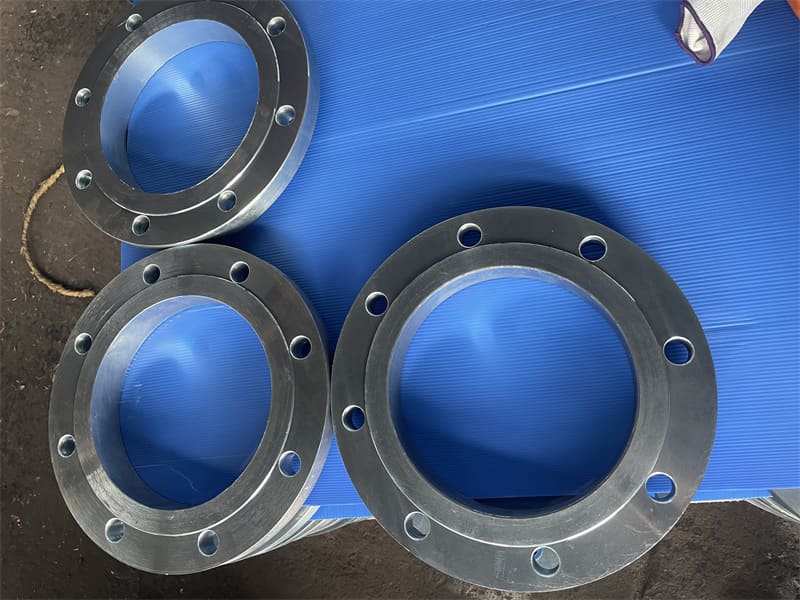

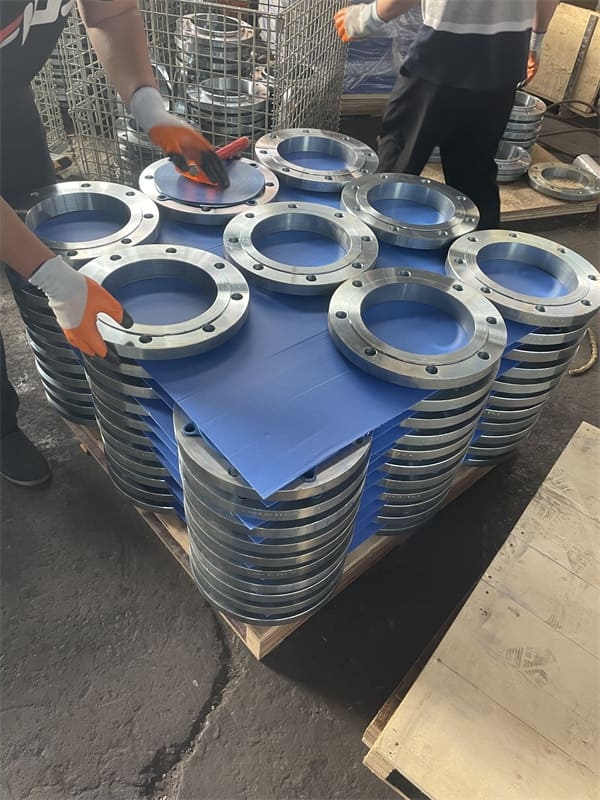

ASME B 16.5 SW Flanges A182 F304 Forged Flanges

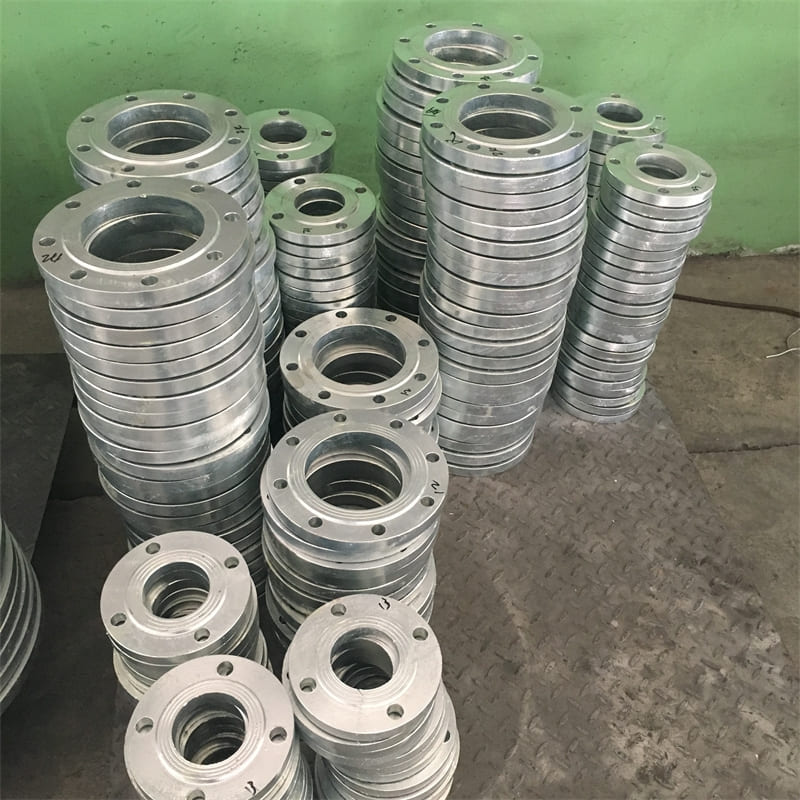

A182 F304 forged flanges are stainless steeel flanges,ASME B16.5 SW flanges are socket weld flanges following American Standard specifications.

ASME B 16.5 SW flanges are common used type in all types of flanges,A182 F304 forged flanges are the most chosen stainless steel flanges because of the affordable price and excellent functions.

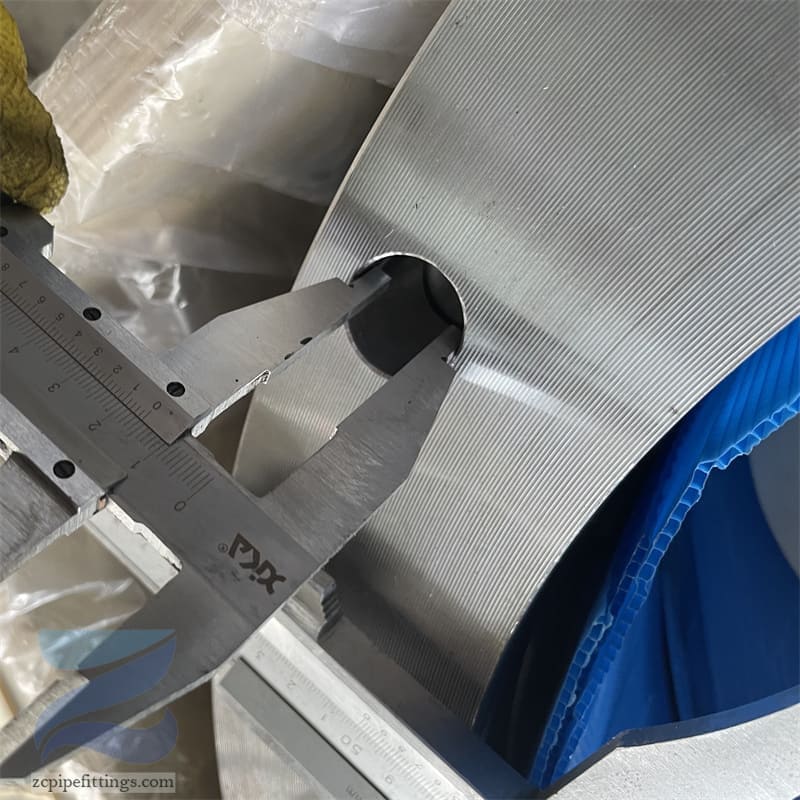

Socket weld flange simplified as SW flange, it has a recessed area (like a shoulder) in the flange bore, this shoulder serves as a guide to set the depth of the pipe that inserted to the flange. Socket welding flange initially designed for high pressure small diameters piping system.

Advantages:

- Socket weld flange could replace threaded flange, to minimize the risky of leakage.

- No need to beveling before welding.

- Welding work outside of the pipe, will not penetrate the pipe bore.

- It is recommended for applications where internal welding operations are particularly difficult.

- Better fatigue life.

Disadvantages:

- Clearance must be left. Cracks between pipes and flanges can cause corrosion problems, mainly in stainless steel piping systems.

- In some processes this flange is also not allowed.

Applications:

An assembly with limited space may be an instance in which a socket weld is selected, provided the pressure class is comparatively low and the fluid is not corrosive or for extremely high temperature service.

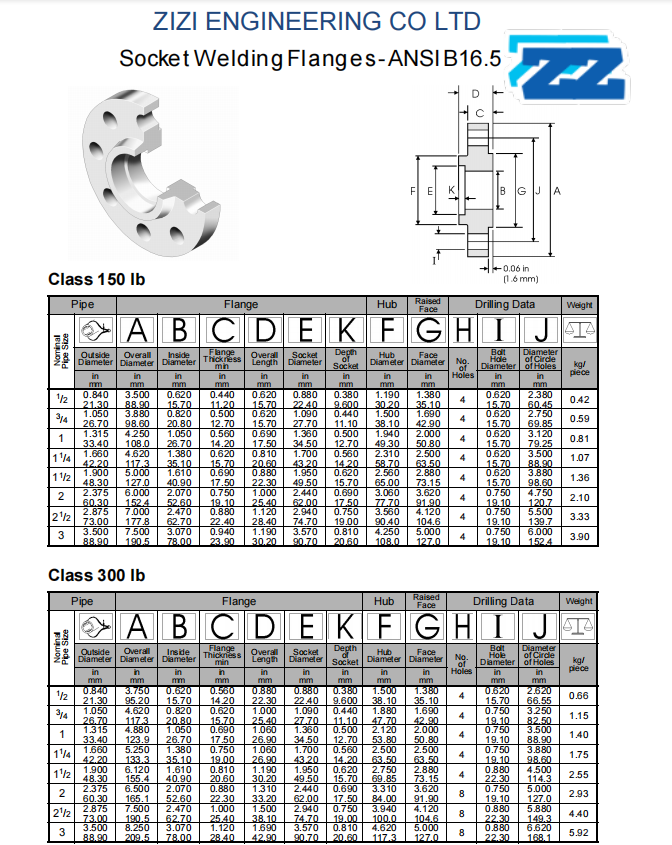

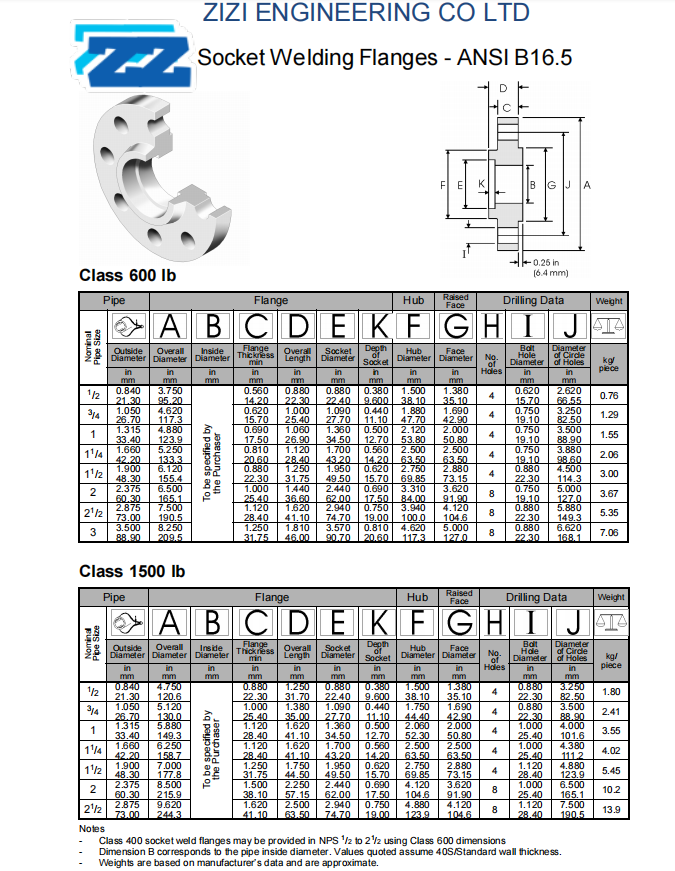

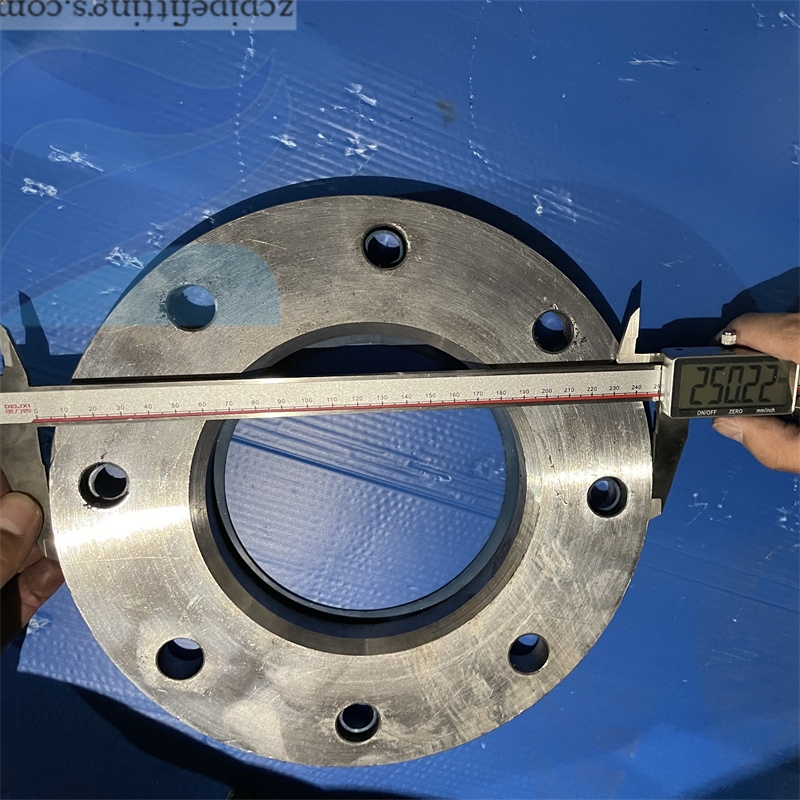

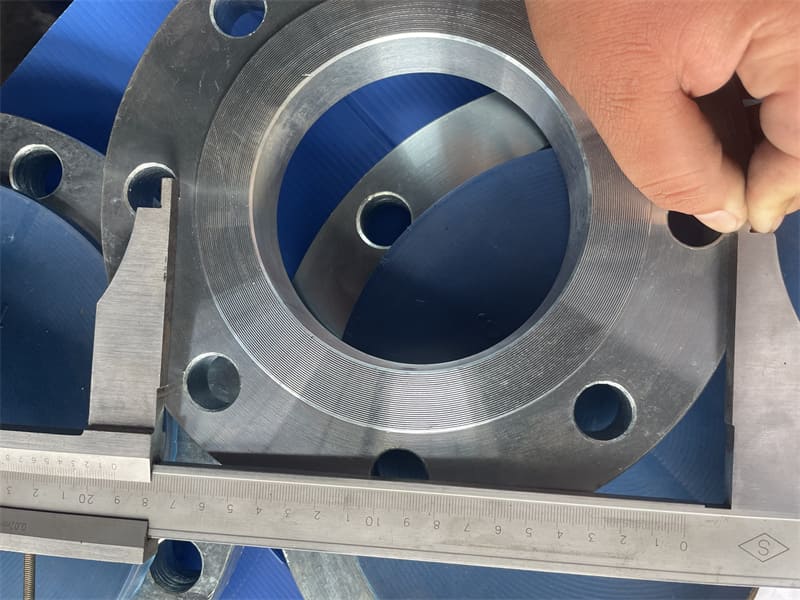

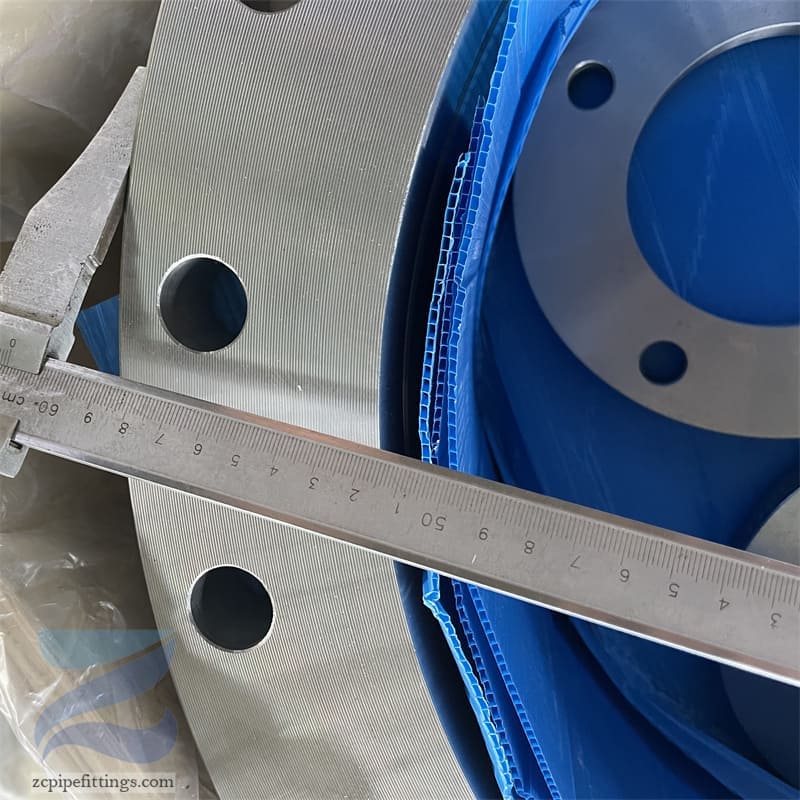

Specification

| Shape | Socket Weld Flange (SW) |

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ASME B16.5, ASME B16.47 Series A/B, EN 1092-1, API 605, MSS SP-44, DIN 2627, DIN 2527, DIN 2558, DIN 2576, DIN 2641, DIN 2655, DIN 2656, DIN2573 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |