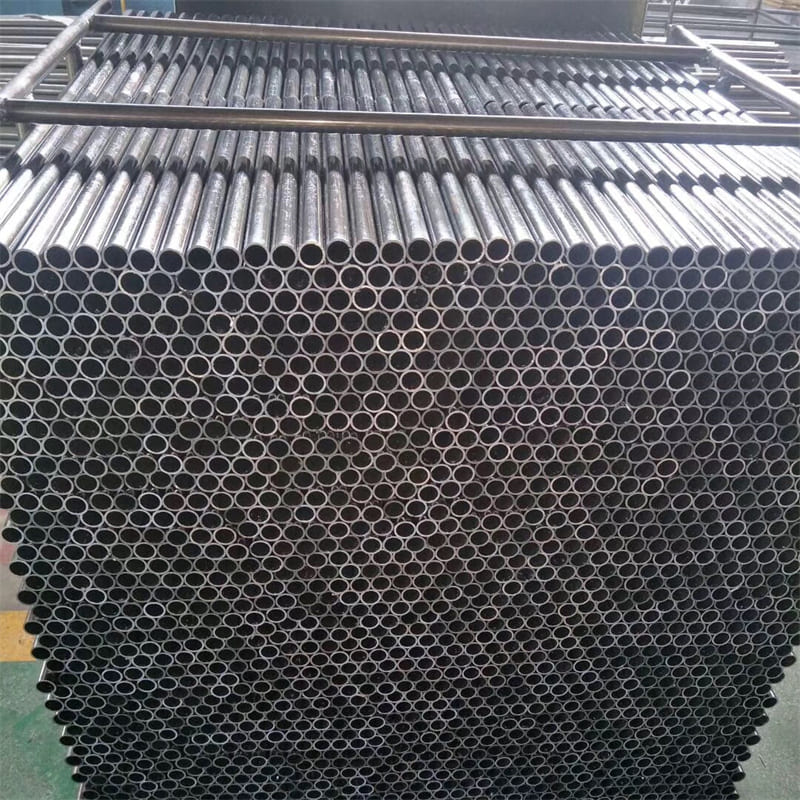

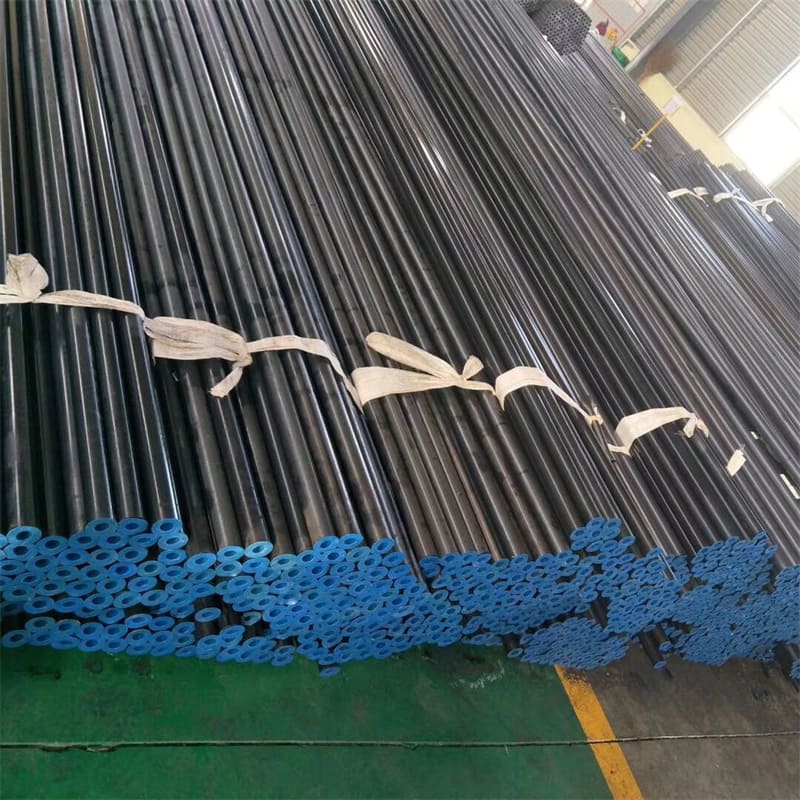

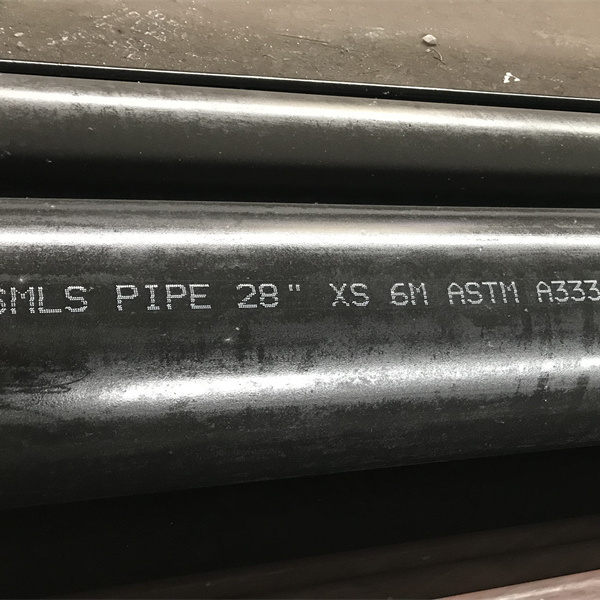

API 5L Seamless Galvanized Pipe

API 5L galvanized pipe is a pipe with a layer of zinc on the surface of the steel pipe. The presence of the zinc layer gives the galvanized pipe good corrosion resistance. The chemical properties of zinc are more active than iron. In a corrosive environment, zinc will oxidize before iron, thereby protecting the steel pipe matrix from corrosion.

API 5L galvanized pipe is a pipe with a layer of zinc on the surface of the steel pipe. The presence of the zinc layer gives the galvanized pipe good corrosion resistance. The chemical properties of zinc are more active than iron. In a corrosive environment, zinc will oxidize before iron, thereby protecting the steel pipe matrix from corrosion.

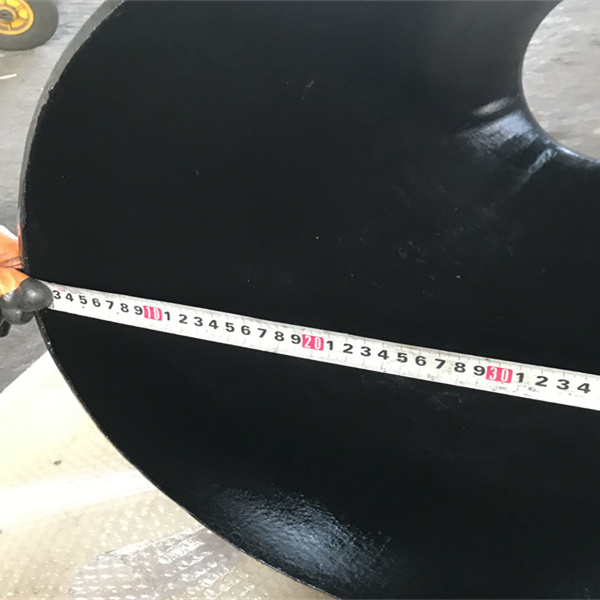

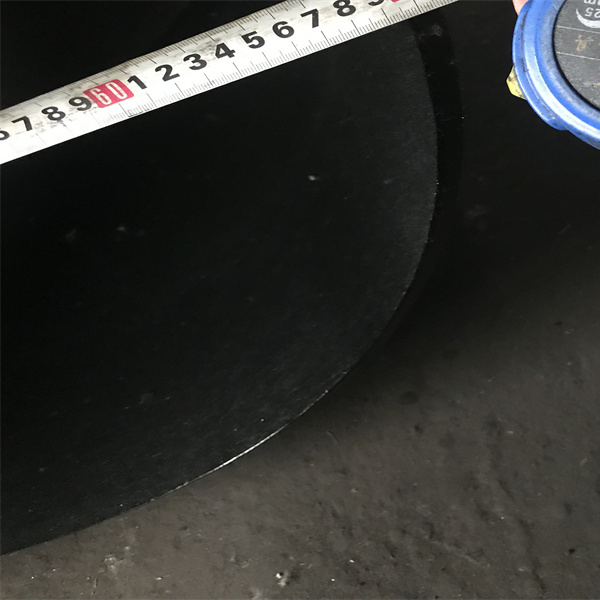

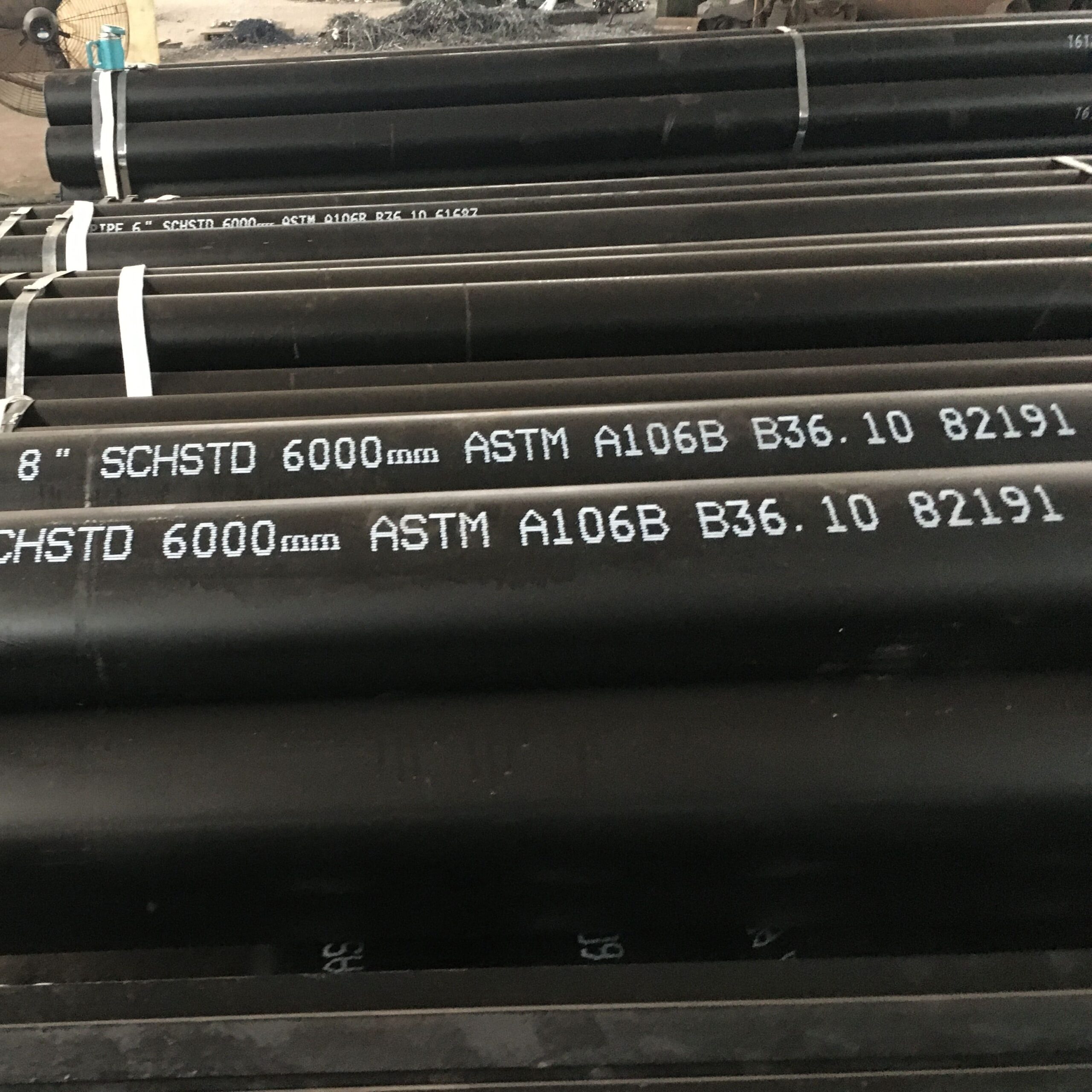

API 5L galvanized pipe is widely used in long-distance oil and natural gas pipelines on land and sea. In the construction of land pipelines, such as the West-East Gas Transmission Project, a large number of pipeline steels are used to build a huge gas pipeline network. In the oil and gas pipelines between offshore oil platforms and land, pipeline steel also plays a vital role. Due to the complexity of the marine environment, higher requirements are placed on the corrosion resistance and fatigue resistance of pipeline steel.