Alloy Steel Pipe Dimensions

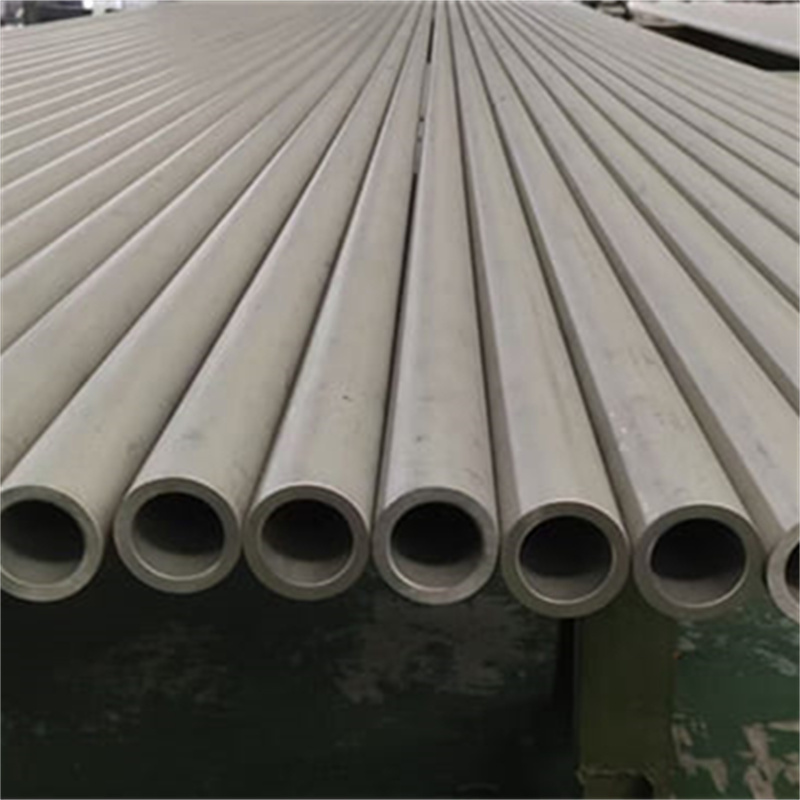

Alloy steel pipe is one material can be chosen for steel pipe.These alloy steel pipes are similar to carbon steel pipe but are still have some differences.The dimensions and specifications can be find in content below.

Alloy steel pipe is always chosen by many industries due to its affordable price and excellent functions.You could find the pipes’ dimensions below.

Alloy steel

In addition to iron and carbon, other alloy elements are added to steel, which is called alloy steel.

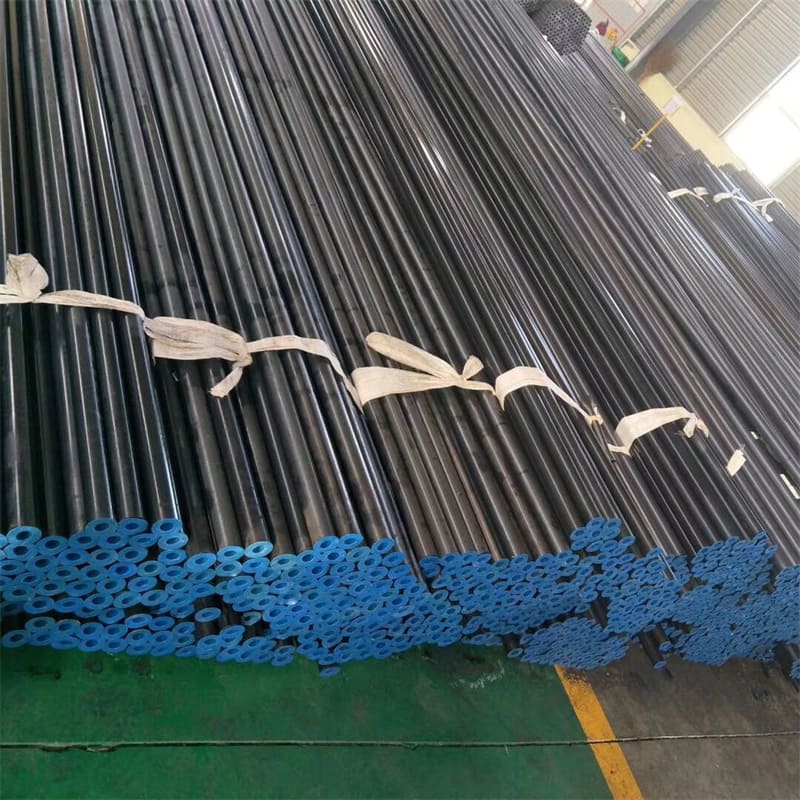

There are two types of pipes:Seamless Pipe and Welded Pipe.

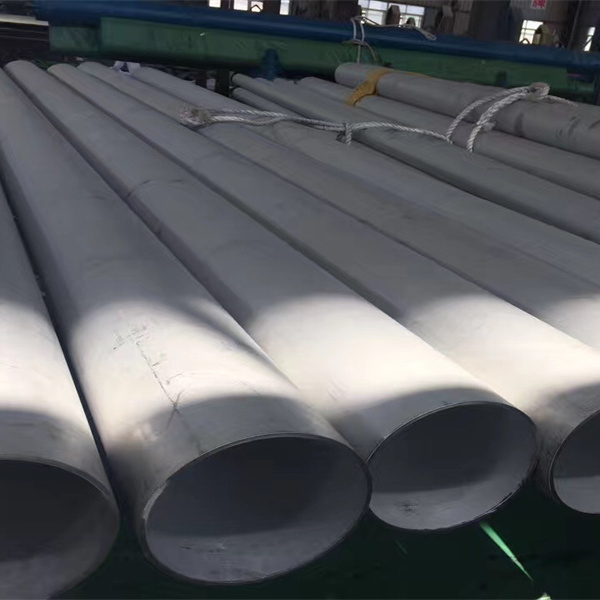

Seamless Pipe

Seamless steel pipe is a kind of circular steel pipe, in which there is no joint around the empty part.

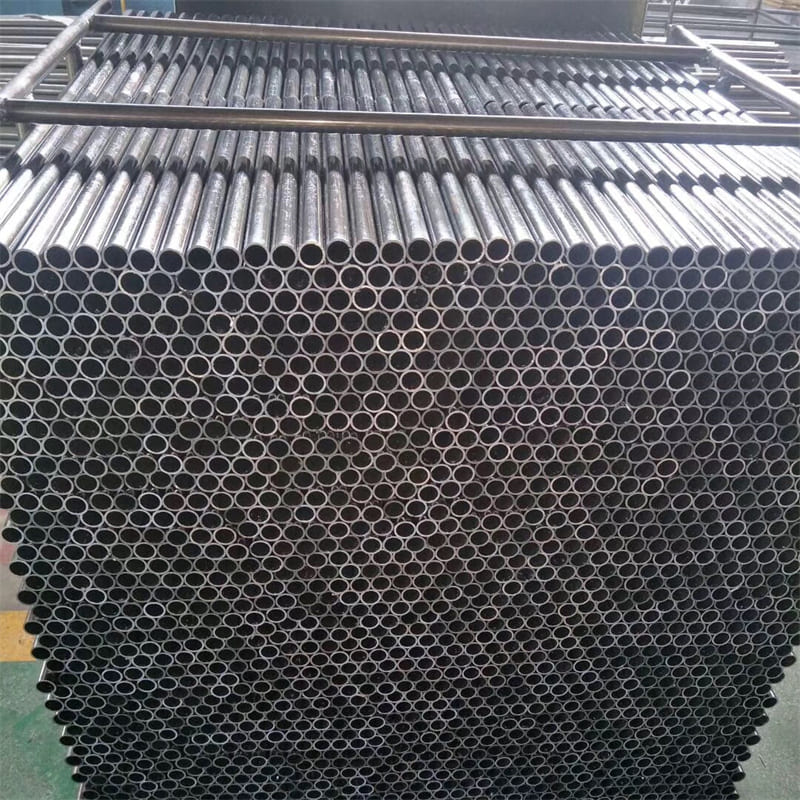

Welded Pipe

Welded steel pipe is a tubular product made of flat plate, which is formed, bent and ready for welding.

Product features

- Alloy steel pipe can withstand extreme conditions and high temperature. This heat resistance makes nickel alloy tubes the preferred material in machines or structures that produce extreme temperatures.

- The oxidation rate of alloy steel pipes is very slow, and they maintain their integrity longer than other metals, especially in the marine environment with particularly serious corrosion problems.

- Alloy steel pipes have very low thermal expansion rate, and they can still maintain a uniform shape and size in high temperature environment.

- 100% recycled, it is suitable for the national strategy of environmental protection, energy-saving and resource-saving.

Applications

- High-temperature services such as Heater tubes

- Low-temperature services such as Cryogenic application

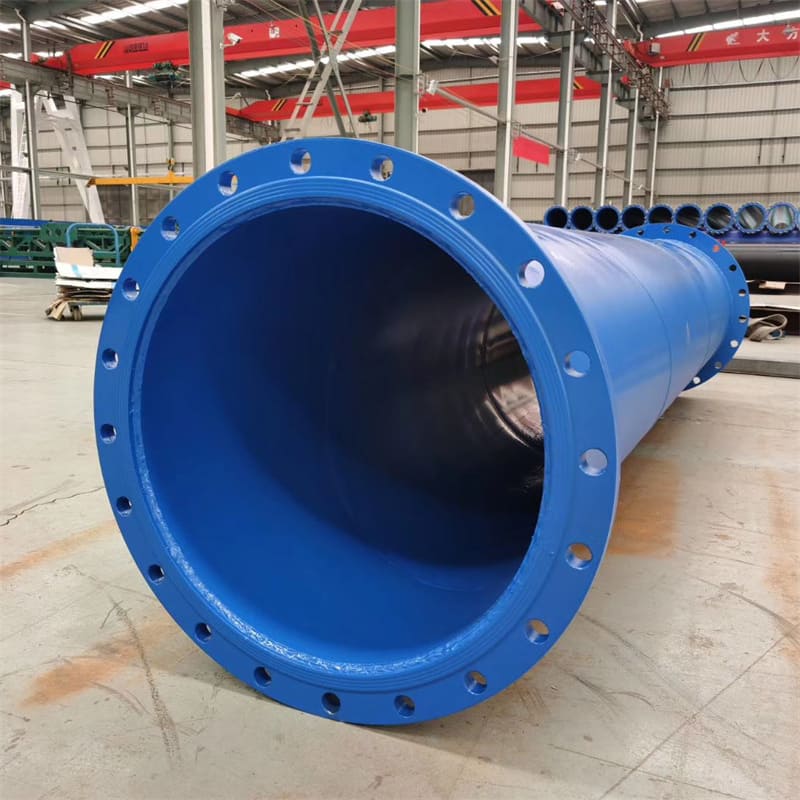

- Very High presser service such as Steam Header

SPECIFICATION

| Type | Seamless and Welded Pipe |

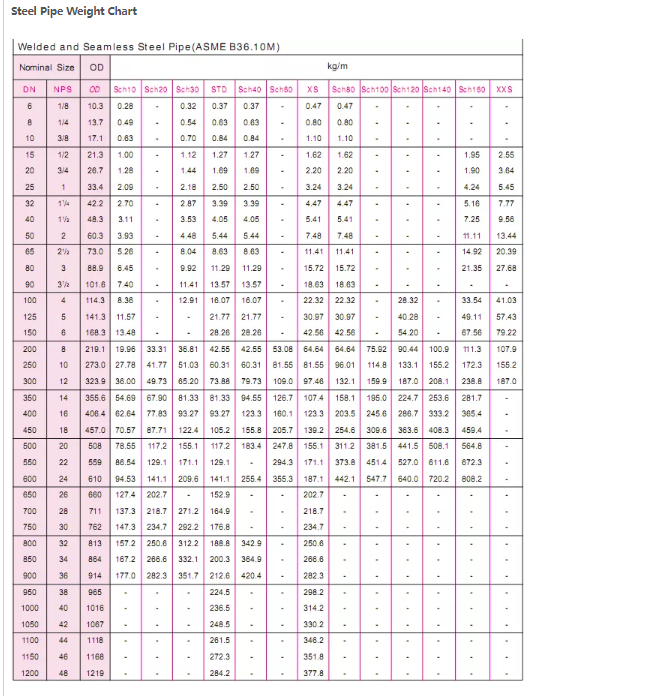

| Size Range | 1/8″- 48″ / DN6 – 1200 |

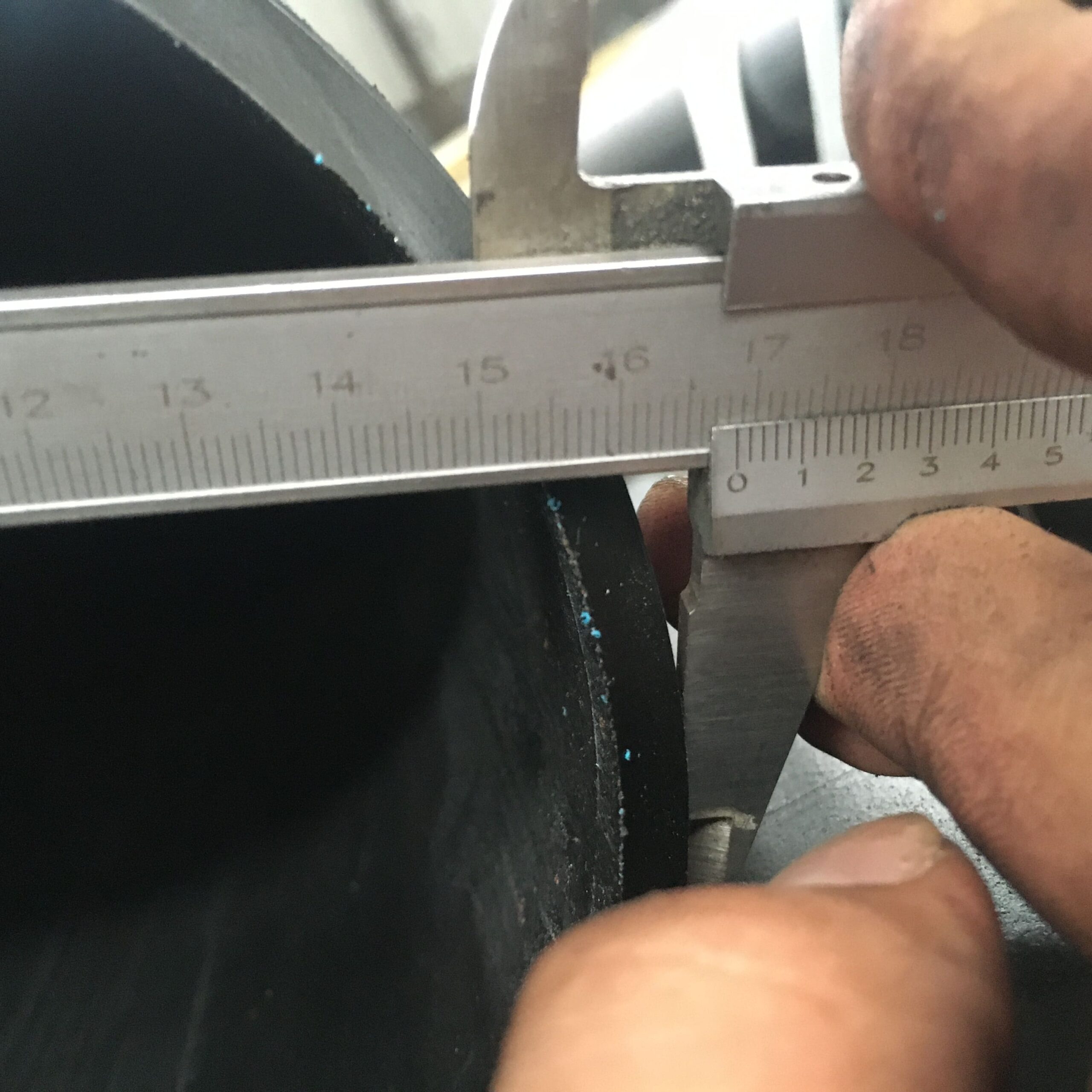

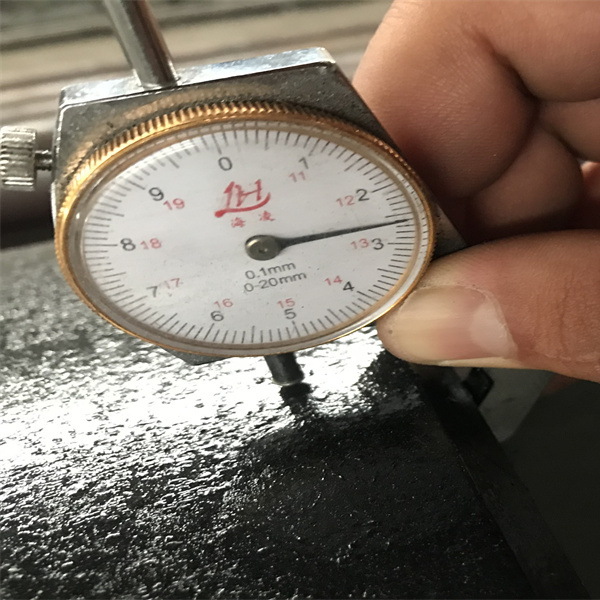

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.10M, ASME B36.19M |

| Surface Treatment | Blasting & Painting , Epoxy Powder FBE, 2PE, 3PE Coating,Mirror, Polish |

| Carbon Steel Grade | ASTM A106B / A53, API 5L B / X42 / 46 / 52 / 56 / 60 / 65 / 70, A333 GR 6 |

| Alloy Steel Grade | ASTM A335 P11 / P12 / P 5 / P9 / P91 / P92, A213 T11 / T12 / T22 / T5 / T9 / T91 / T92. 15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel Grade | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L, S32205, S31803, 32750, 32760, S32550 |