Alloy Steel Butt Weld pipe Cap

Alloy steel butt-weld pipe caps are mainly used to close pipeline systems to ensure that the fluid in the pipeline will not leak.It is usually welded at the end of the pipeline to provide a reliable sealing effect.

Alloy steel butt weld pipe caps are mainly used to close pipeline systems to ensure that the fluid in the pipeline will not leak. It is usually welded at the end of the pipeline to provide a reliable sealing effect. Alloy steel butt-weld pipe cap have good corrosion resistance and high temperature resistance. This enables it to maintain stable performance in harsh working environments and extend its service life. At the same time, the alloy material also has high strength and toughness, and can withstand certain pressure and impact.

Alloy steel butt weld pipe caps are widely used in pipeline systems in industries such as petroleum, chemical, electric power, and metallurgy. Especially in high-pressure, high-temperature or highly corrosive environments, butt weld pipe caps can provide a reliable sealing effect to ensure the safe operation of the pipeline system.

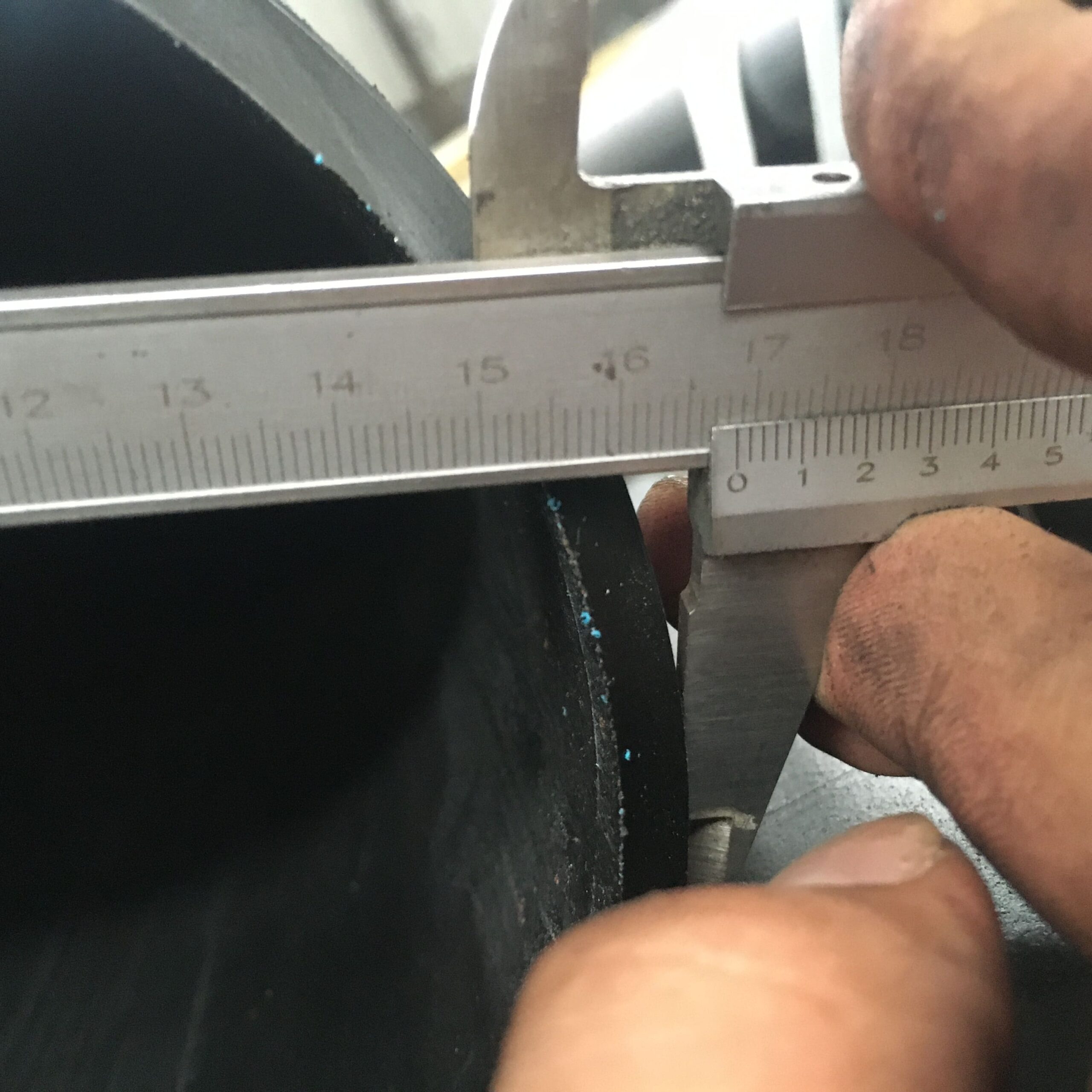

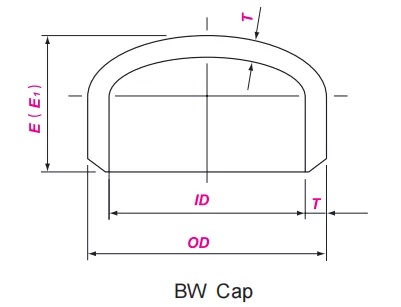

ASME B16.9 Steel Pipe Cap Dimensions

| DN | NPS | OD | E | E1 |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 25 | 25 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 11/4 | 42.2 | 38 | 38 |

| 40 | 11/2 | 48.3 | 38 | 38 |

| 50 | 2 | 60.3 | 38 | 44 |

| 65 | 21/2 | 73.0 | 38 | 51 |

| 80 | 3 | 88.9 | 51 | 64 |

| 90 | 31/2 | 101.6 | 64 | 76 |

| 100 | 4 | 114.3 | 64 | 76 |

| 125 | 5 | 141.3 | 76 | 89 |

| 150 | 6 | 168.3 | 89 | 102 |

| 200 | 8 | 219.1 | 102 | 127 |

| 250 | 10 | 273.0 | 127 | 152 |

| 300 | 12 | 323.8 | 152 | 178 |

| 350 | 14 | 355.6 | 165 | 191 |

| 400 | 16 | 406.4 | 178 | 203 |

| 450 | 18 | 457.0 | 203 | 229 |

| 500 | 20 | 508.0 | 229 | 254 |

| 550 | 22 | 559.0 | 254 | 254 |

| 600 | 24 | 610.0 | 267 | 305 |

| 650 | 26 | 660.0 | 267 | — |

| 700 | 28 | 711.0 | 267 | — |

| 750 | 30 | 762.0 | 267 | — |

| 800 | 32 | 813.0 | 267 | — |

| 850 | 34 | 864.0 | 267 | — |

| 900 | 36 | 914.0 | 267 | — |

| 950 | 38 | 965.0 | 305 | — |

| 1000 | 40 | 1016.0 | 305 | — |

| 1050 | 42 | 1067.0 | 305 | — |

| 1100 | 44 | 1118.0 | 343 | — |

| 1150 | 46 | 1168.0 | 343 | — |

| 1200 | 48 | 1219.0 | 343 | — |

Advantages of Alloy Steel Butt Weld Cap

High strength and toughness: The alloy material makes the pipe cap have high strength and toughness, which can withstand the high pressure and high temperature environment in the pipeline system. This strength property helps to ensure the safety and stability of the pipeline system.

Corrosion resistance: Alloy steel butt weld pipe caps are usually made of corrosion-resistant alloy materials, which can resist the erosion of various corrosive media. This helps to extend the service life of the pipeline system and reduce maintenance and replacement costs.

Good sealing: Installed by welding, the alloy steel butt weld pipe cap can provide a reliable sealing effect to prevent fluid leakage in the pipeline. This sealing is essential to prevent environmental pollution and ensure production safety.

Easy to install and maintain: The installation process of the alloy steel butt weld pipe cap is relatively simple, usually completed by welding, and does not require additional complex tools or equipment. In terms of maintenance, it is only necessary to check the integrity of the weld regularly, which is easy to operate and manage.