Alloy Steel A182 Threaded Threadolet Dimentions

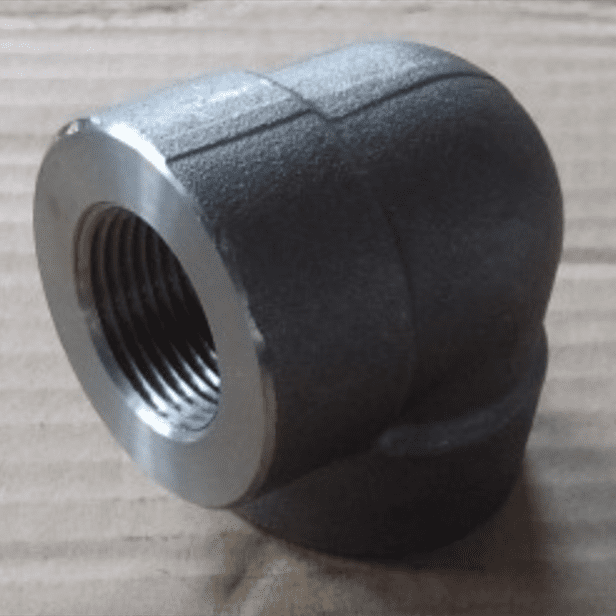

This makes a 90° branch and comes in full size or reducing for a straight piece of pipe

Production Description

Alloy Steel A182 Threaded Dimentions utilizes the basic Weldolet configuration, provides a threaded outlet branch connection. It has the same basic design as a weldolet. However the main difference is the fitting has a female threaded connection to link to the branch connection. This makes a 90° branch and comes in full size or reducing for a straight piece of pipe

Product features

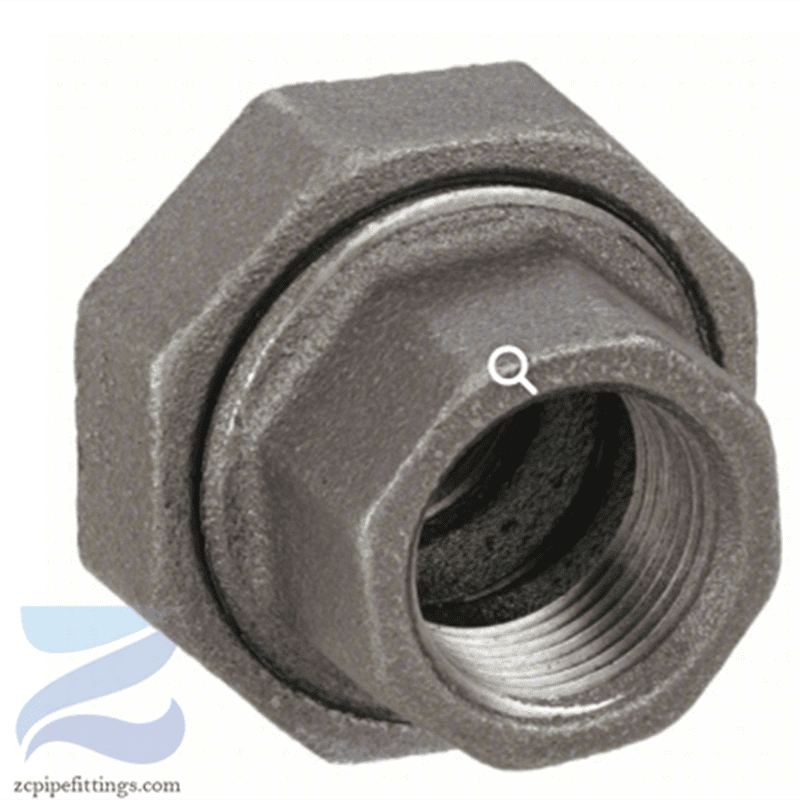

- Threadolet does not require welding, it can be installed through the thread.

- It typically is in the size range of 1/2″ to 2” and is welded over a hole either drilled or burned in the pipe.

- Threadolet considered to a threaded fitting, and it is manufactured in 3000 and 6000 classes.

Procuct Specification

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs |

| Standard | MSS SP-97 |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Carbon Steel | ASTM A105 / A105N |

| Low Temp Carbon Steel | ASTM A350 LF2 / LF3 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

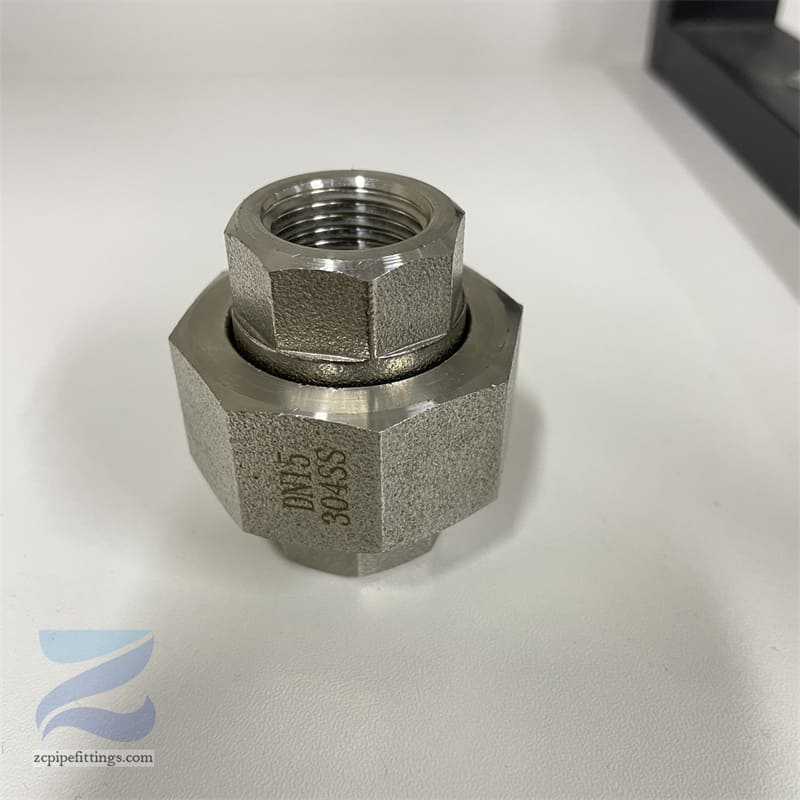

| Stainless Steel | A STM A182 F304/304L/304H, 316/316L, 310S, 317 ,347, 904L, 321 |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

ASME MSS SP 97 Threadolet Dimensions

Production Material

These Stainless Steel A182 Threaded Cross are best known for their heat resistance, creep strength and tensile strength. Machined and fabricated to meet your diverse piping requirements, these pipes fittings exhibit excellent corrosion resistance in a wide range of atmospheric environments.

The specification of ASTM A182 Forged Pipe Fittings includes forged fittings, stainless steel, rolled alloy, forged alloy, pipe flanges as well as high-temperature service. Later then forgings and hot working, it would be cooled down to a certain temperature before heat treatment.

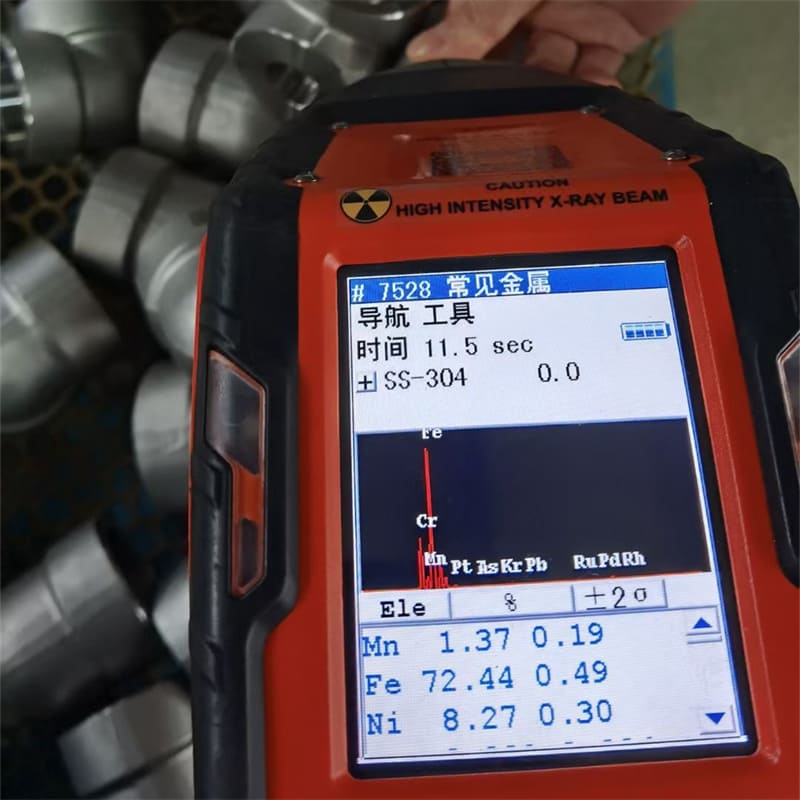

Stainless Steel A182 Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

Stainless Steel A182 Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

Stainless Steel A182 Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18-09 | X5CrNi18-10 |

Application

- Bolier

- Shipbuilding

- Electric Industries

- Chemical Industries

- Gas Processing Industries

- Food Processing Industries

- Power Generation Industries

- Petroleum and Naturalgas Industries

Drawing Details