Home » Forged Steel Fittings » Alloy Steel A182 Socket Weld Elbow Dimension

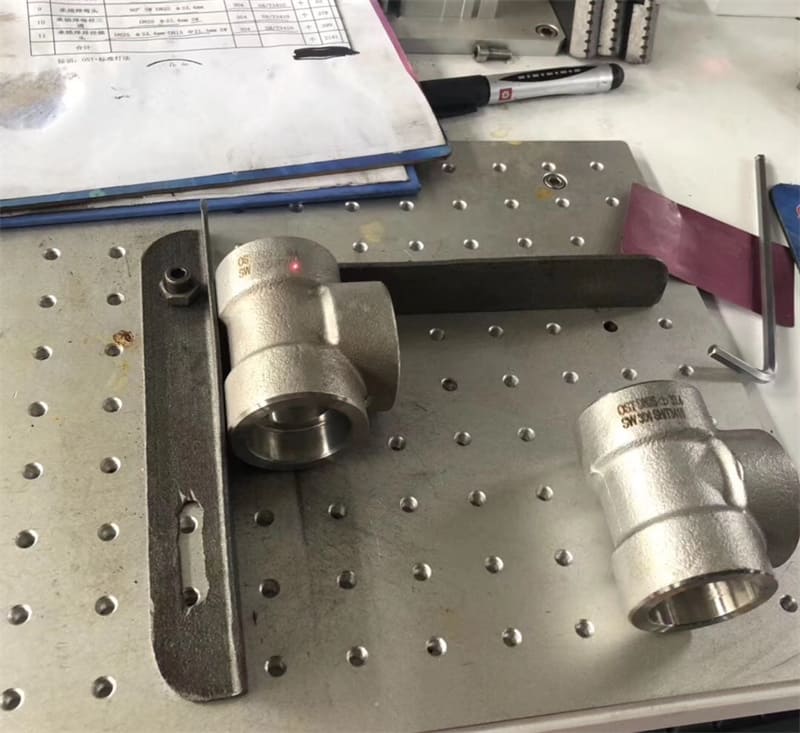

Alloy Steel A182 Socket Weld Elbow Dimension

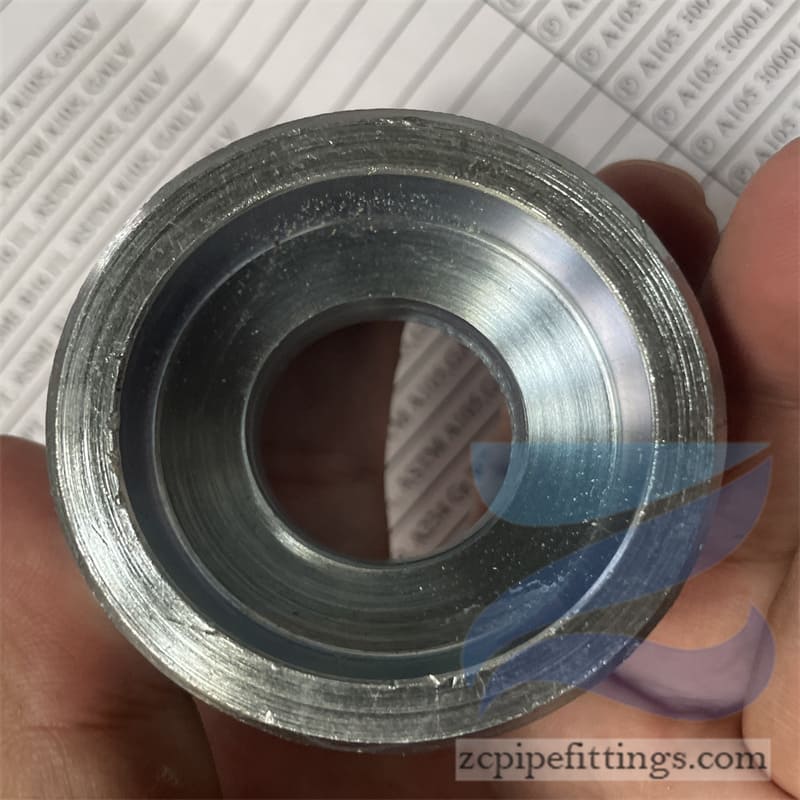

Socket weld Elbow forged fitting has varieties of features such as reliability, durability and dimensional precision.

Contact US

Get Price

Share:

Content

Production Description

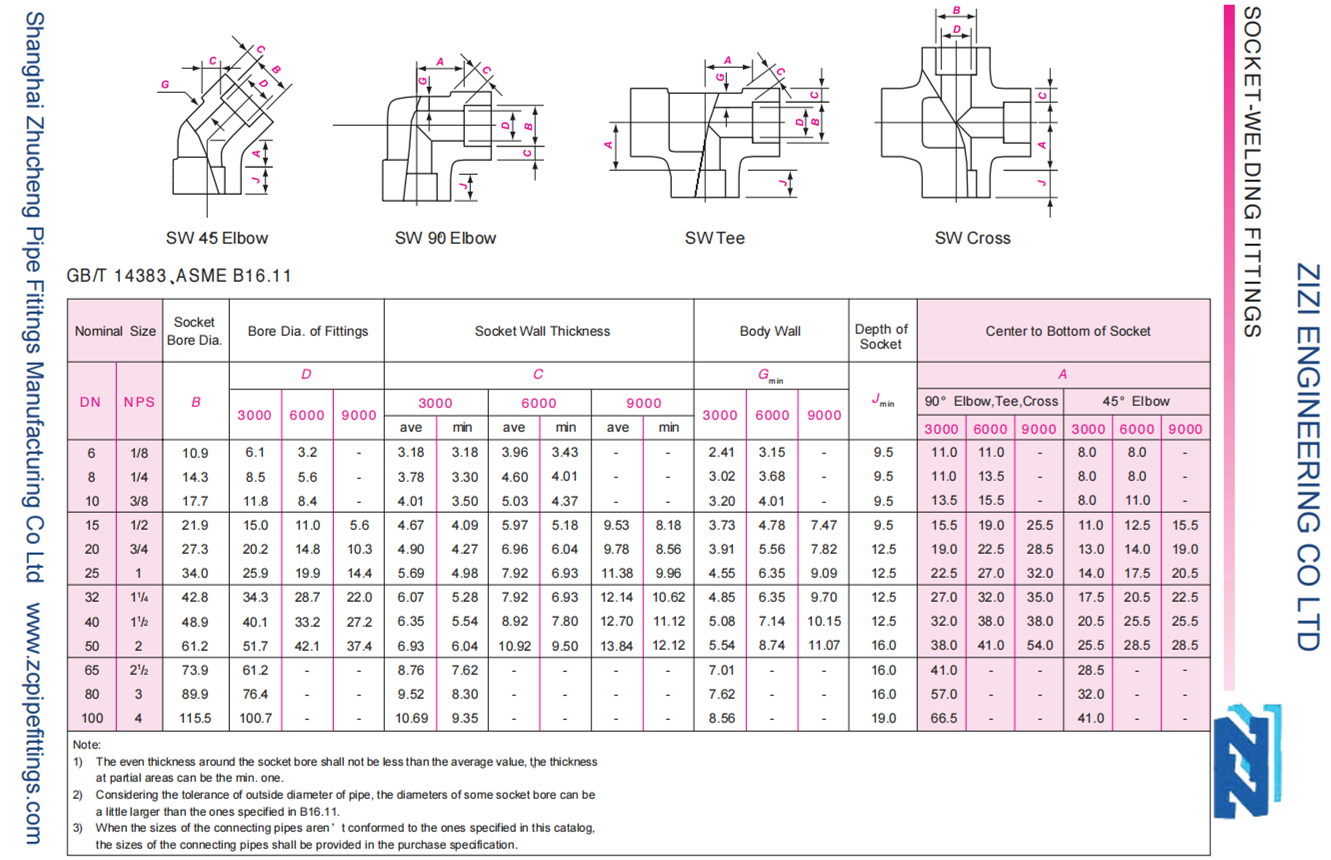

SW 45 Deg ELBOW

45 Degree Socket Weld Elbow is utilized to Put through two pipes with the same ostensible breadth to form the pipe turn 45 degrees.

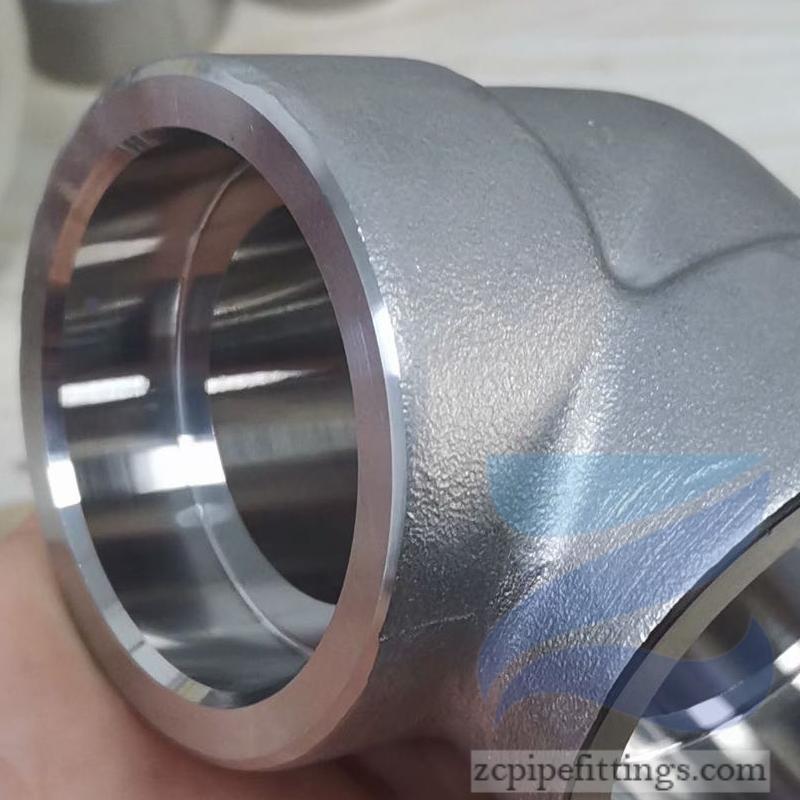

SW 90 Deg ELBOW

Socket Weld 90 Degree Elbow makes 90°changes of course within the run of pipe to create a channeling framework.

Equal Elbow

Alloy Steel A182 Socket Weld Elbow Dimension Dimensions is an elbow with the same diameter at both ends, which is characterized in that the pipeline connecting the two necks belongs to the same specification.

Reducing Elbow

Reducing elbows connect two pipes of different diameters to reduce the diameter when the pipe rotates.

Product features

- The socket weld elbow is resistance corrosion/pitting/oxidation/stress corrosion cracking and crevice corrosion.

- It is having high tensile strength and good dimensional accuracy to own

- It withstands heavy loads and also withstands in the high-temperature atmosphere.

- Socket weld Elbow forged fitting has varieties of features such as reliability, durability and dimensional precision.

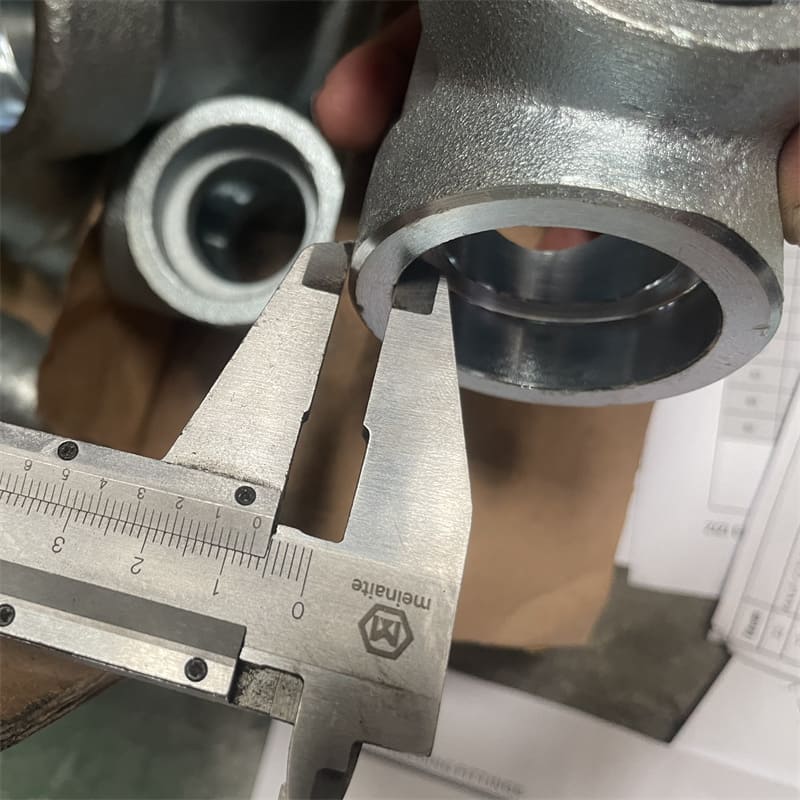

Product Specification

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Inquiry

More Socket Weld Fittings