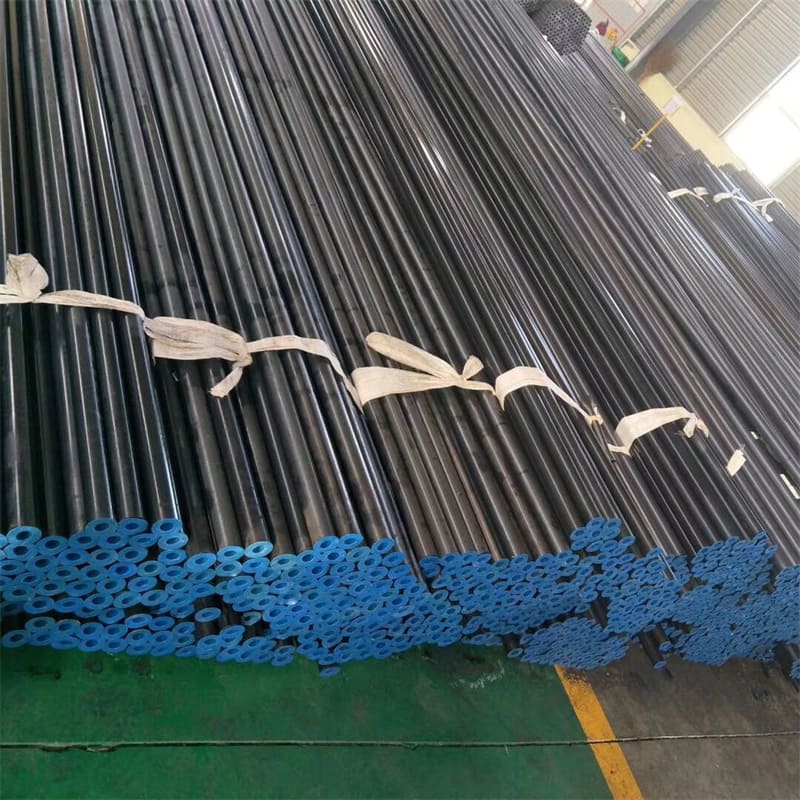

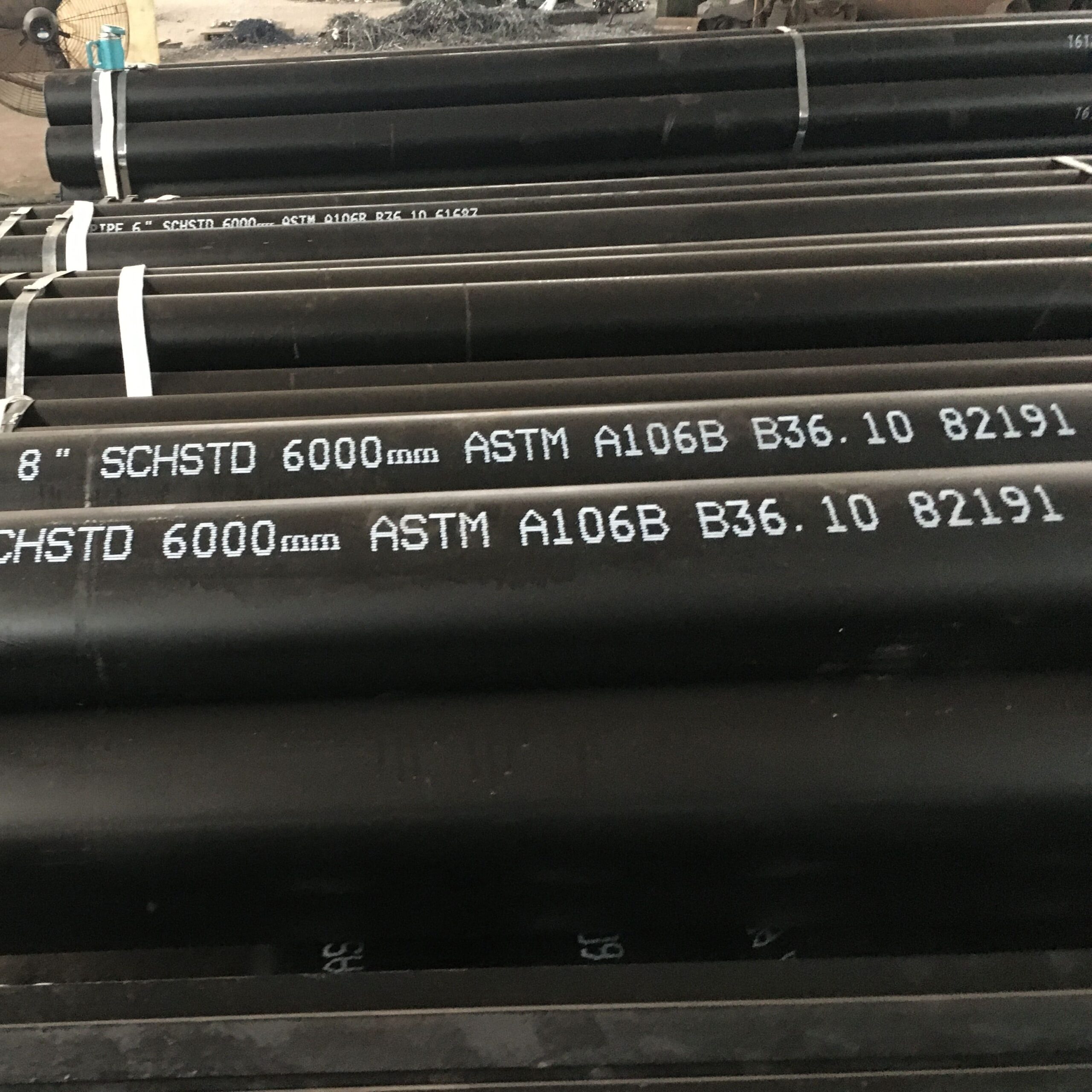

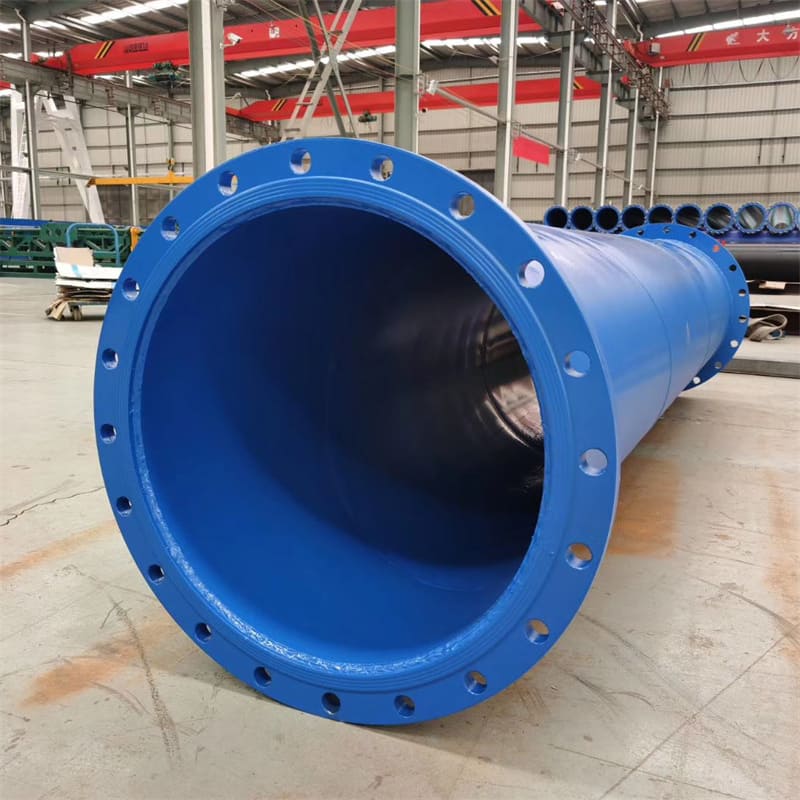

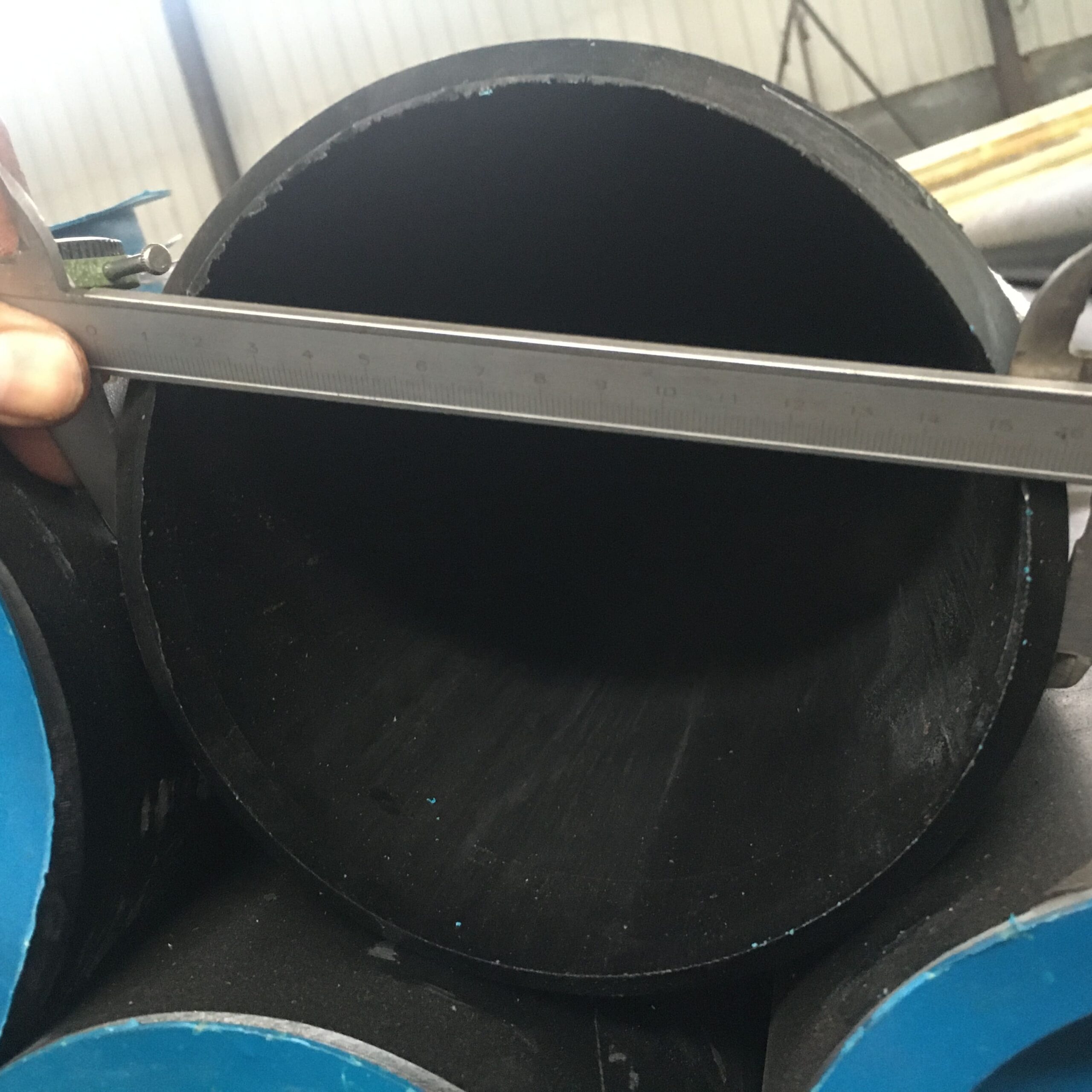

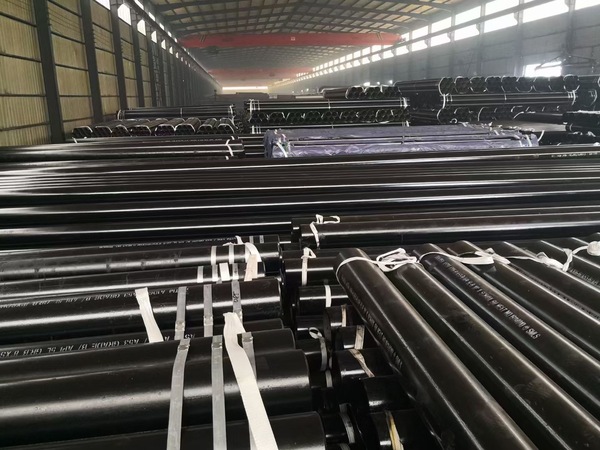

A333 Grade 6 Pipe

A333 Grade 6 steel pipe is a steel pipe material specially designed for low temperature environment. It can maintain good mechanical and physical properties under low temperature conditions to ensure safe and reliable use in low temperature engineering.

A333 Grade 6 pipe is a steel pipe material specially designed for low temperature environment. It can maintain good mechanical and physical properties under low temperature conditions to ensure safe and reliable use in low temperature engineering. In low temperature environment, the toughness of the material is crucial. Low temperature steel pipes need to have sufficient impact toughness to prevent brittle fracture at low temperature. Low temperature steel pipes are widely used in petrochemical, nuclear industry and other fields. Its production process is complicated and requires multiple links such as smelting, rolling, cold working and heat treatment.