A312 TP 304L Steel Pipe

A312 WP304L steel pipe is a hollow long round steel, mainly made of stainless steel. Stainless steel is steel that does not rust in weak corrosive media such as air and fresh water.

A312 WP304L steel pipe is a hollow long round steel, mainly made of stainless steel. Stainless steel is steel that does not rust in weak corrosive media such as air and fresh water. It generally contains chromium (Cr), and the chromium content is usually not less than 10.5%. Chromium forms an extremely thin, strong, fine, stable chromium-rich oxide film (passivation film) on the surface of stainless steel to prevent the continued infiltration and oxidation of oxygen atoms, thereby obtaining corrosion resistance.

Stainless steel pipes are widely used in industrial pipelines such as petroleum, chemical, medical, food, light industry, mechanical instruments, and mechanical structural components

Specification Of A312 WP304L Steel Pipe

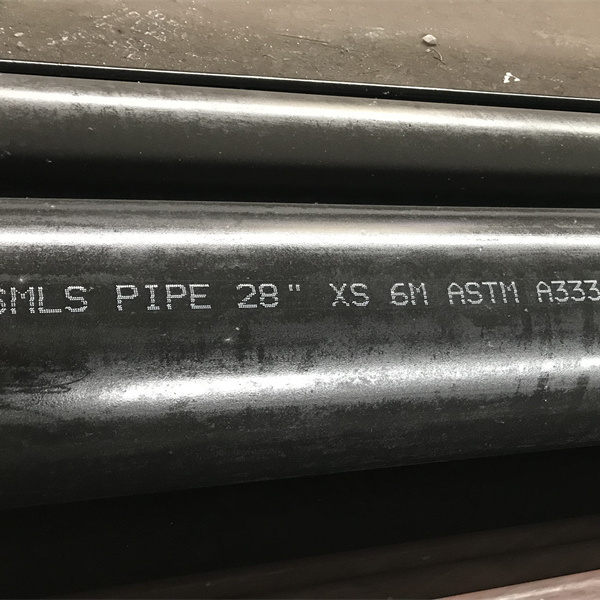

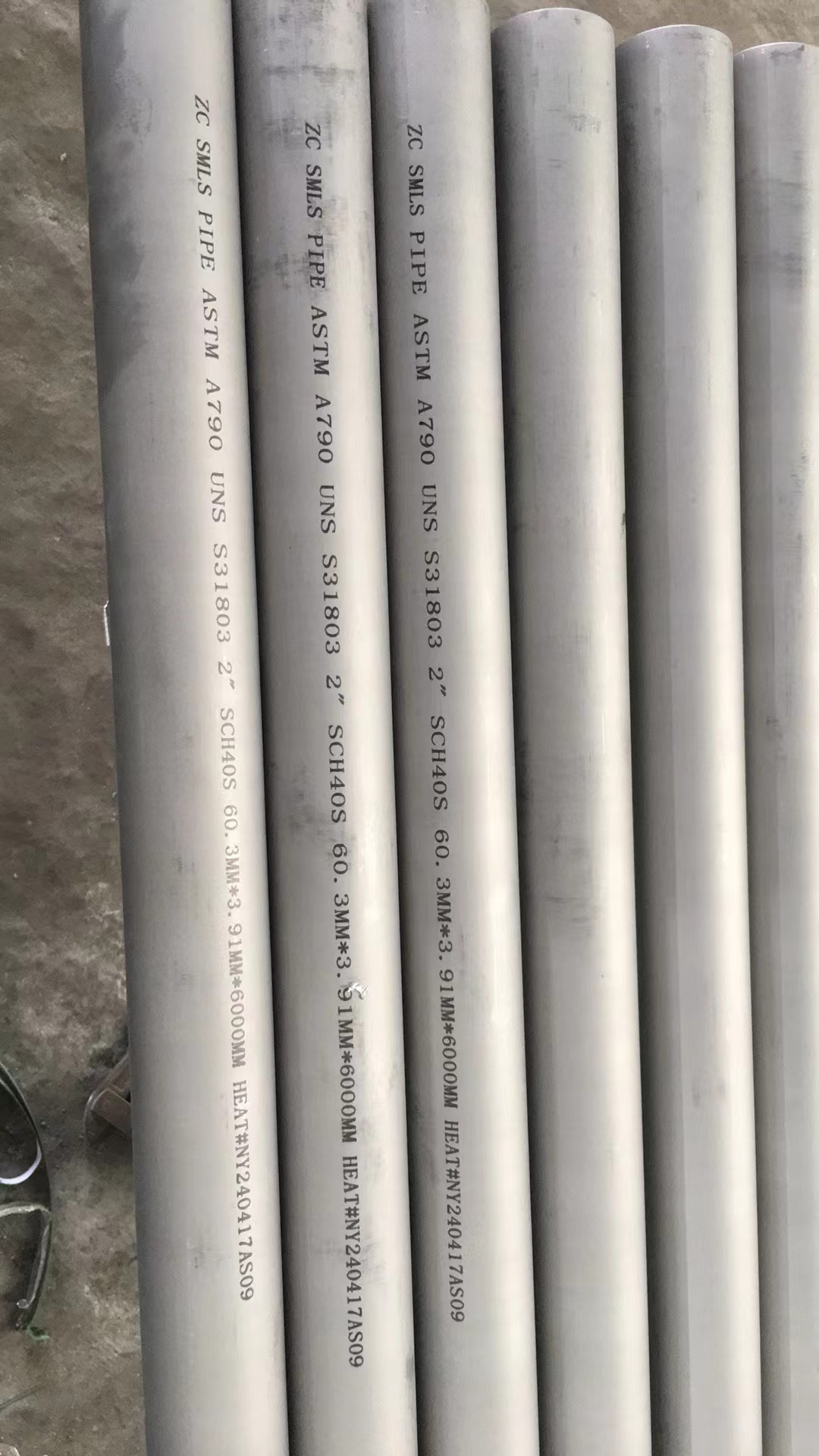

| Processing Method | Seamless and Welded |

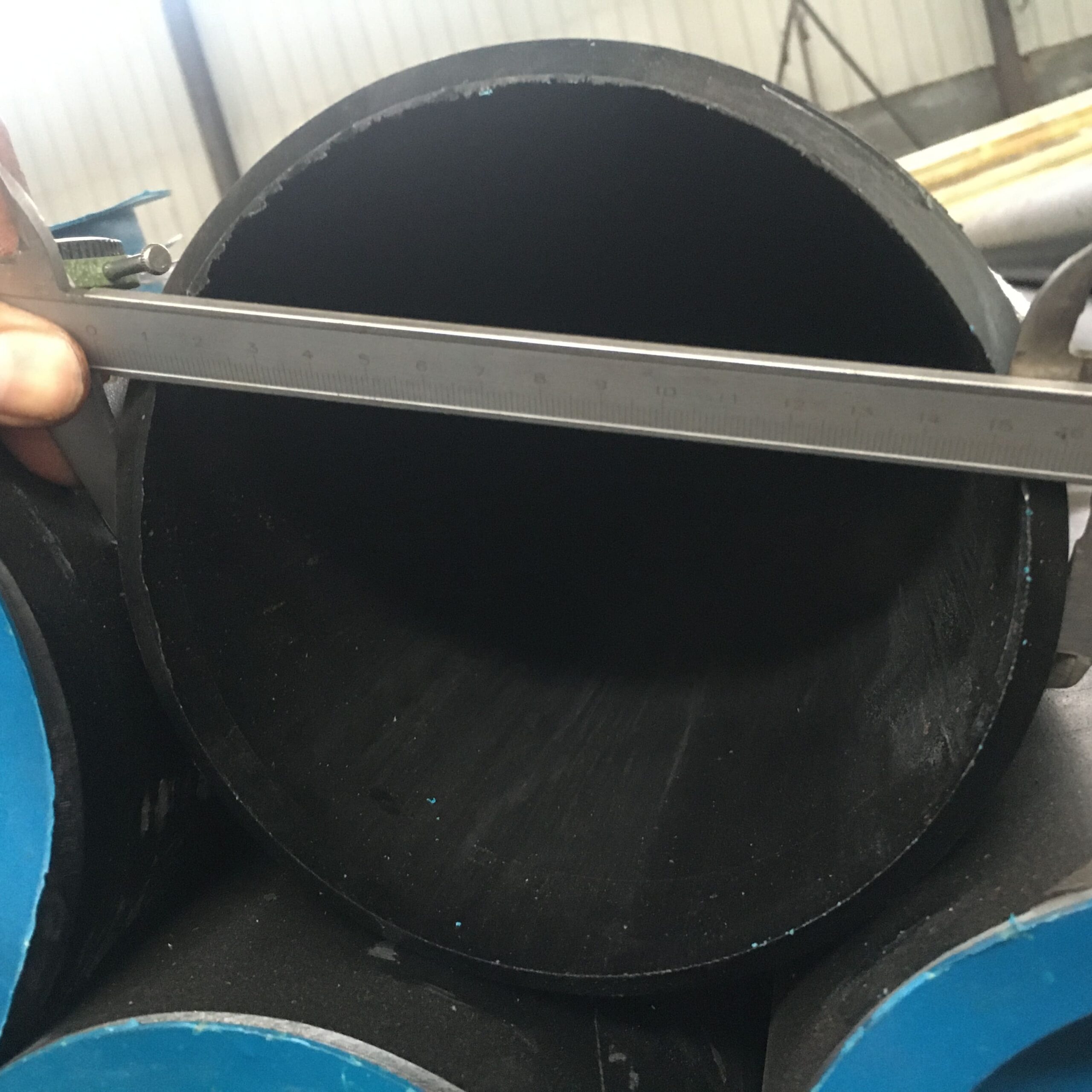

| Size Range | 1/8” – 30” / DN6 – 750 |

| Thickness Schedule | SCH 10S- SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.19 |

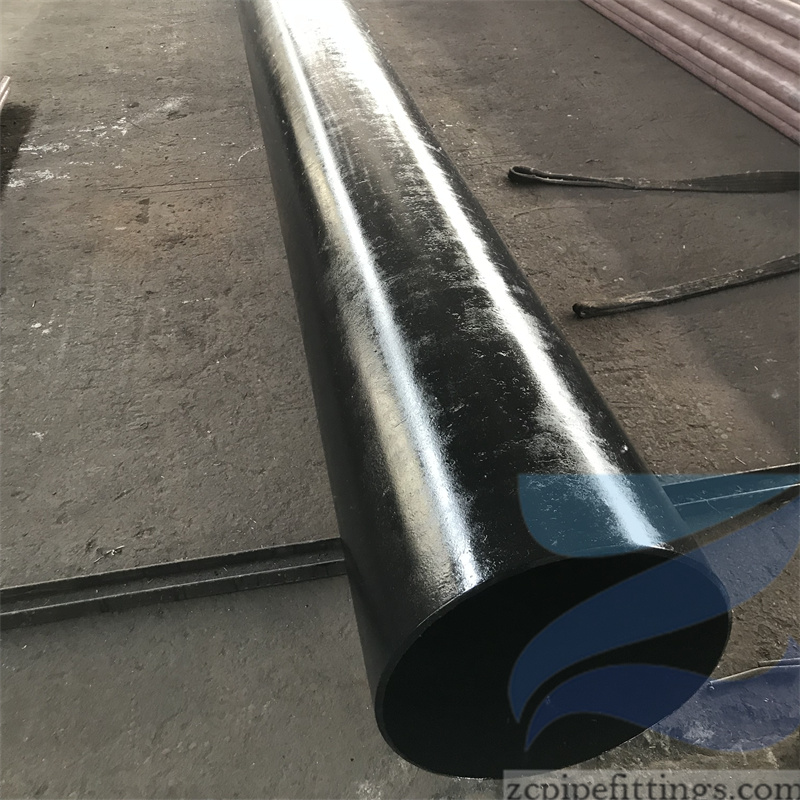

| Surface Treatment | Polish , Mirror , Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L, S32205, S31803, 32750, 32760, S32550 |