A234 WPB Threaded Coupling

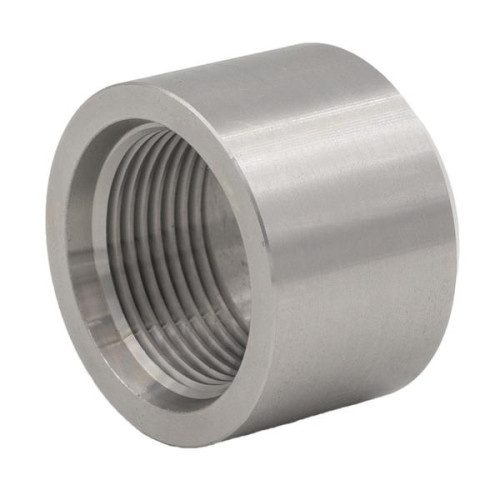

A234 WPB threaded coupling mainly consists of a main body and thread structures at both ends. The main body is usually cylindrical, and its length varies according to different specifications and usage requirements.

A234WPB threaded coupling mainly consists of a main body and thread structures at both ends. The main body is usually cylindrical, and its length varies according to different specifications and usage requirements. The threads at both ends are its key structural features. These threads are processed according to specific standards, and common ones are imperial threads (such as NPT – American standard taper pipe thread) and metric threads (such as M series threads). The pitch, tooth angle and other parameters of the thread are precisely controlled to ensure a tight connection with the corresponding pipe or pipe fittings.

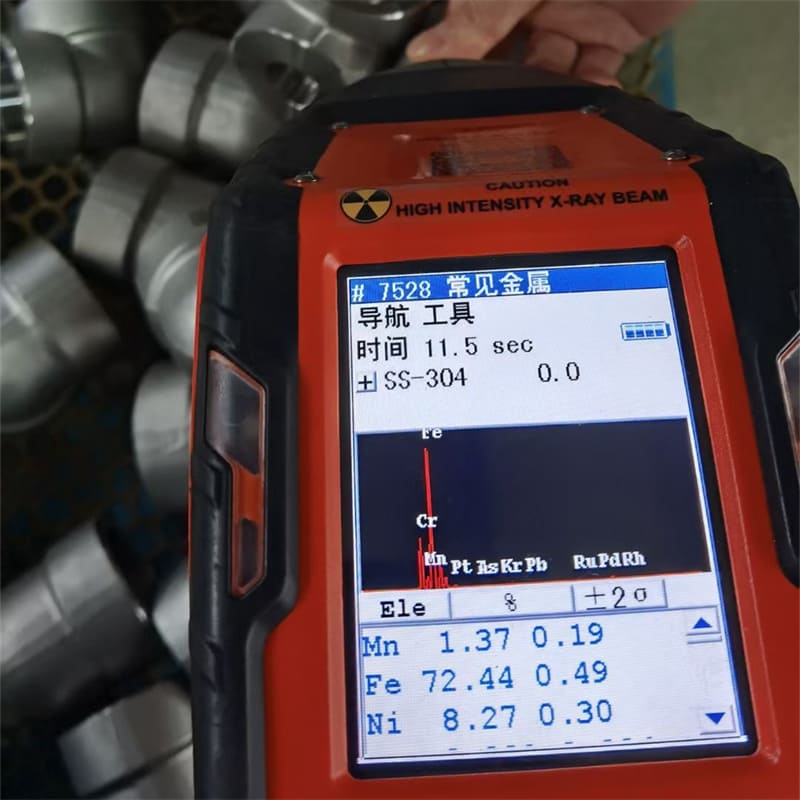

ASTM A234 is Standard Specification for steel pipe fittings includes carbon and alloy steel material for moderate and high temperature services. It covers steel fittings of seamless and welded types. Steel Pipe fittings are applied in pressure pipelines and in pressure vessel fabrications. These fittings material consist of killed steel, forgings, bars, plates, seamless or HFW (fusion welded) pipe products, with filler metal added.

Specification of A234 WPB Threaded Coupling

Standard: ASME B16.11, BS3799, GB/T14626

Diameter: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Ratings: 2000LB, 3000LB, 6000LB

Thread Type: NPT, BSPP, BSPT, PT, PF

Surface: Anti-rust Oil and Galvanized

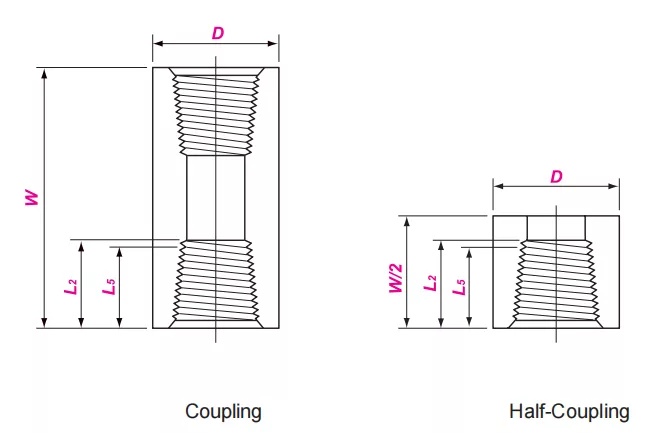

ASME B16.11 Threaded Coupling Dimensions

| Nominal Size | End-to-End | Outside Diameter | Length of Thread | |||

| DN | NPS | W | D | L 5 min | L 2 min | |

| 3000 & 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 32 | 16 | 22 | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 19 | 25 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 22 | 32 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 28 | 38 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 35 | 44 | 12.7 | 13.9 |

| 25 | 1 | 60 | 44 | 57 | 14.7 | 17.3 |

| 32 | 11/4 | 67 | 57 | 64 | 17.0 | 18.0 |

| 40 | 11/2 | 79 | 64 | 76 | 17.8 | 18.4 |

| 50 | 2 | 86 | 76 | 92 | 19.0 | 19.2 |

| 65 | 21/2 | 92 | 92 | 108 | 23.6 | 28.9 |

| 80 | 3 | 108 | 108 | 127 | 25.9 | 30.5 |

| 100 | 4 | 121 | 140 | 159 | 27.7 | 33.0 |

Application of Threaded Coupling

Removability

The A234 WPB threaded coupling connects the pipe through threads, and this connection method has good removability. During the installation, maintenance or overhaul of the pipeline system, if a certain section of the pipe or pipe fitting needs to be replaced, the pipe connected by the threaded coupling can be easily disassembled.

Connection tightness

The threaded connection can provide a relatively tight connection effect. When the threaded coupling and the pipe are screwed together through the threads, the mutual engagement between the threads can effectively prevent the fluid in the pipe from leaking.

Adaptable to various pipe diameters

The A234 WPB threaded coupling can be manufactured according to different pipe nominal diameters and has strong versatility. Whether it is a small-diameter pipe or a large-diameter pipe, you can find a matching threaded coupling for connection.

Applicable to different pipe materials

The threaded coupling can not only be used to connect pipes of the same material, but also to a certain extent to connect pipes of different materials. In the pipe connection of some small refrigeration equipment, copper refrigeration pipes may be connected to carbon steel pipes. The threaded coupling can be used as a connection method to achieve transition connection between pipes of different materials while meeting the connection strength and sealing requirements.