A234 WP11 Elbow

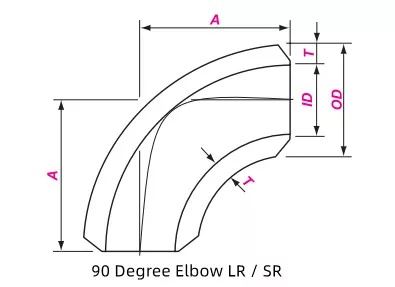

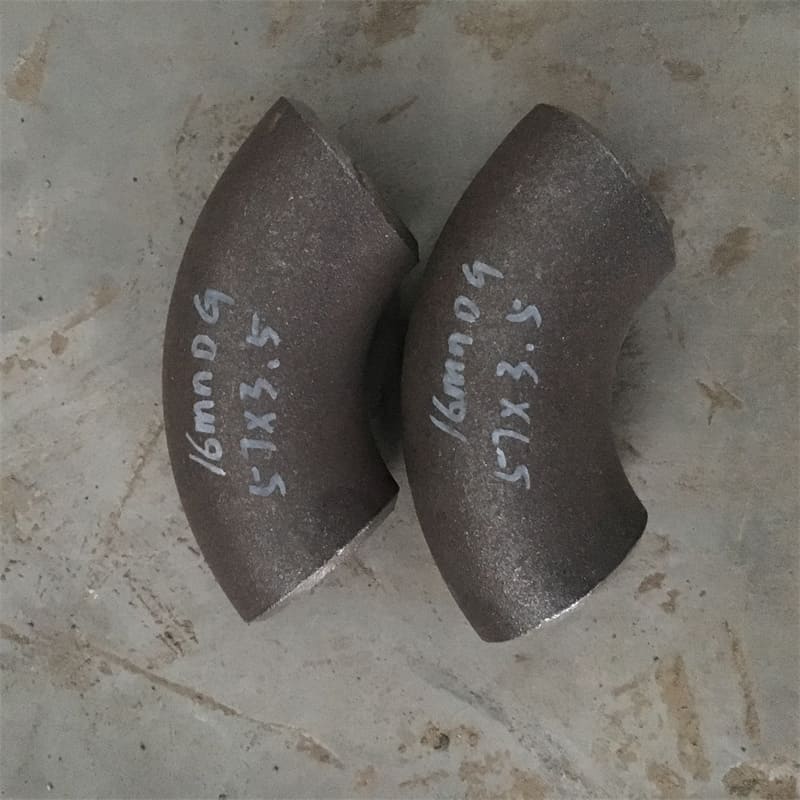

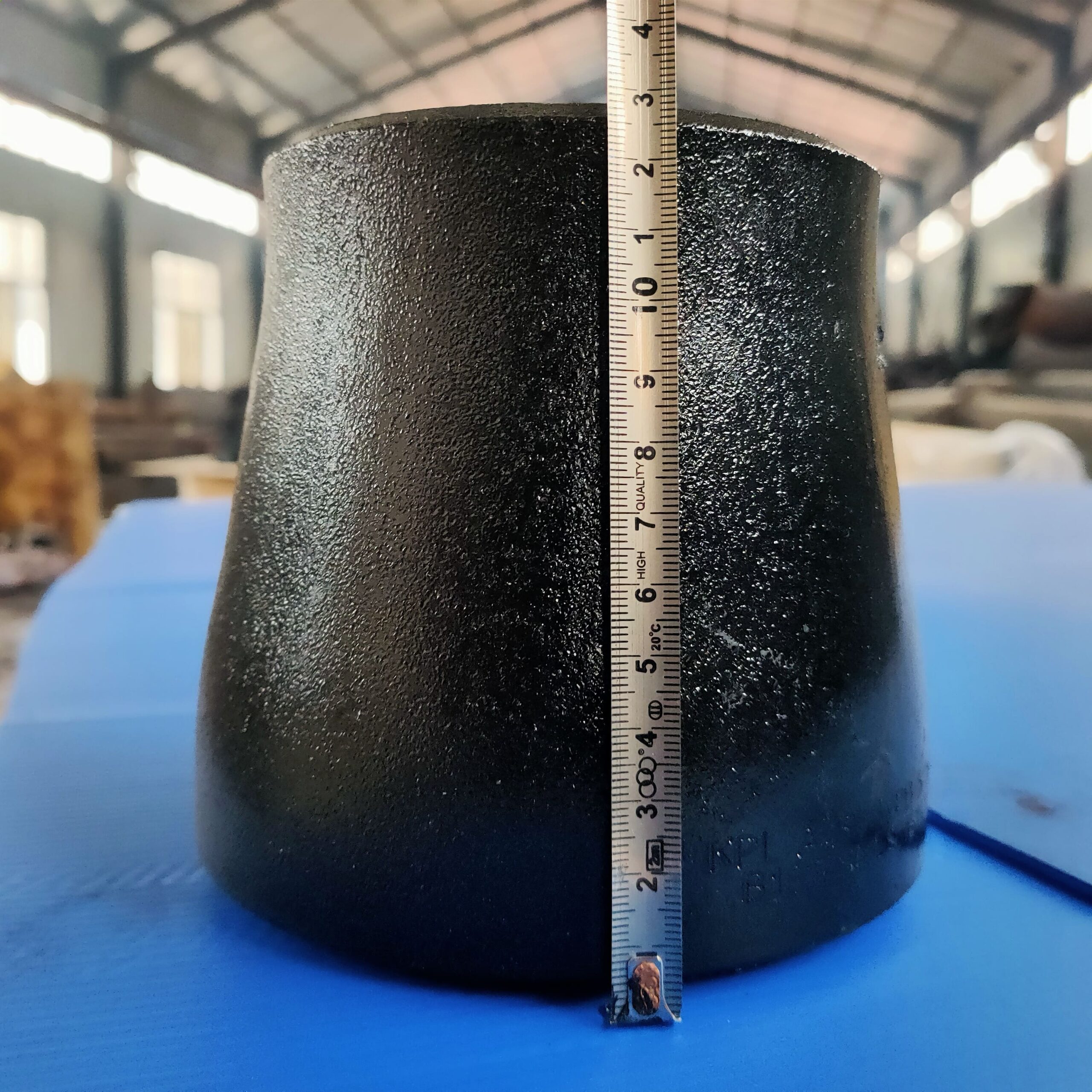

A234 WP11 elbow is a pipe fitting used to change the direction of the pipeline. It is made of alloy steel. Its basic structure is a curved tubular part, usually with connection interfaces at both ends to connect with other pipeline components.

A234 WP11 elbow is a pipe fitting used to change the direction of the pipeline. It is made of alloy steel. Its basic structure is a curved tubular part, usually with connection interfaces at both ends to connect with other pipeline components.

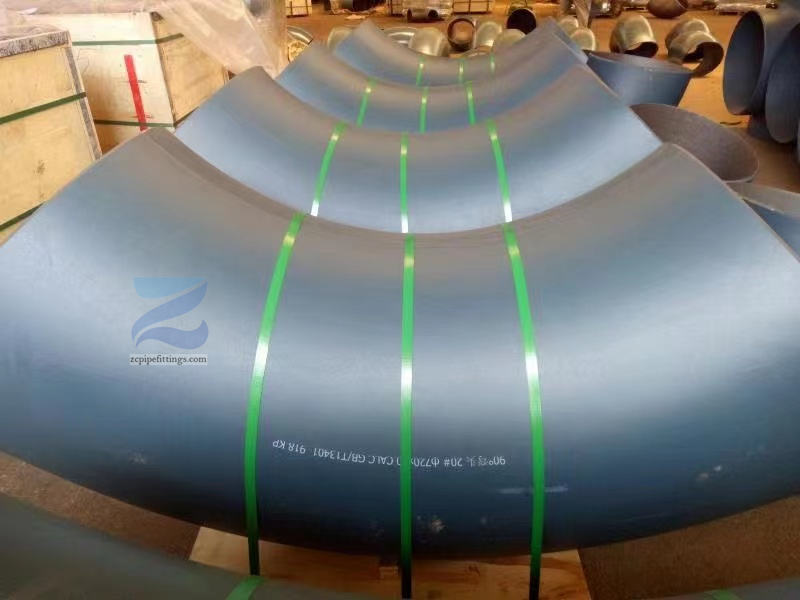

Due to the high strength characteristics of alloy steel, alloy steel elbows can withstand higher pressure in the pipeline. In the high-pressure transmission pipelines of the petrochemical industry, alloy steel elbows can ensure the safe operation of the pipeline system and prevent leakage or rupture accidents due to excessive pressure.

Good corrosion resistance and high temperature performance make alloy steel elbows have a long service life. In the pipeline system of the seawater desalination plant in the marine environment, alloy steel elbows can resist the corrosion of seawater, reduce the frequency of replacing pipe fittings, and reduce maintenance costs.