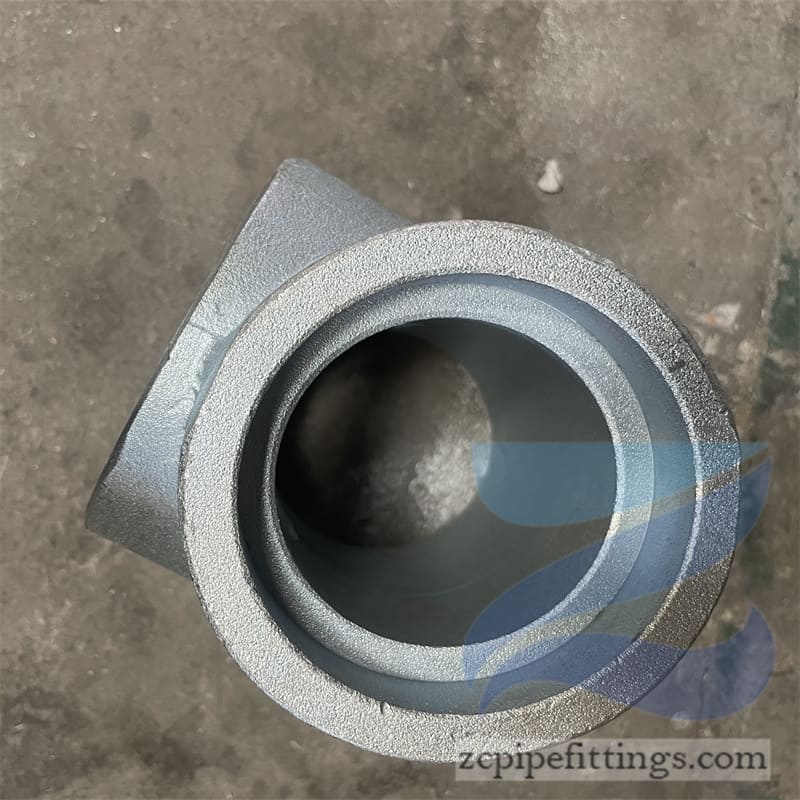

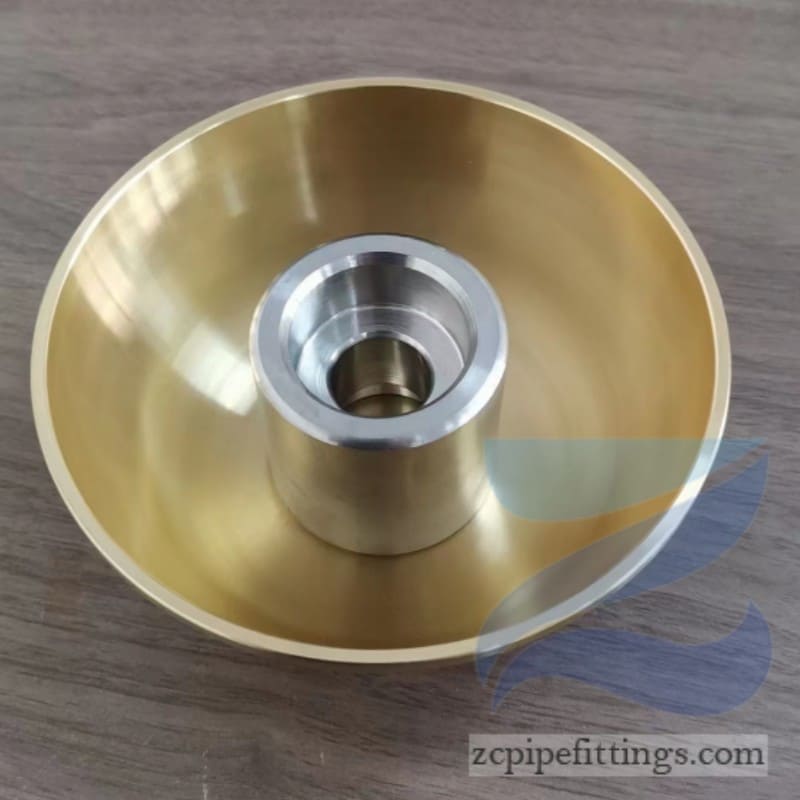

A182 F22 Sockolet

Alloy socket branch pipe seat is a pipe fitting made of alloy material, used to connect the branch pipe to the main pipe. It mainly consists of two parts: the socket and the body.

Alloy socket branch pipe seat is a pipe fitting made of alloy material, used to connect the branch pipe to the main pipe. It mainly consists of two parts: the socket and the body. The socket is the part connected to the branch pipe, and its inner diameter is slightly larger than the outer diameter of the branch pipe. The branch pipe is inserted into the socket and welded to form a sealed connection; the body is welded to the main pipe. This structural design makes the connection between the branch pipe and the main pipe stable and well sealed.

Alloy socket branches are widely used in various industrial fields, such as petroleum, chemical industry, natural gas, electricity, metallurgy, etc. Especially in high pressure, high temperature and corrosive environment, alloy socket branches play an irreplaceable role.

Specification of Sockolet

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs |

| Standard | MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N |

| Low Temp Carbon Steel | ASTM A350 LF2/LF3 |

| Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317, 347, 904L, 321 |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

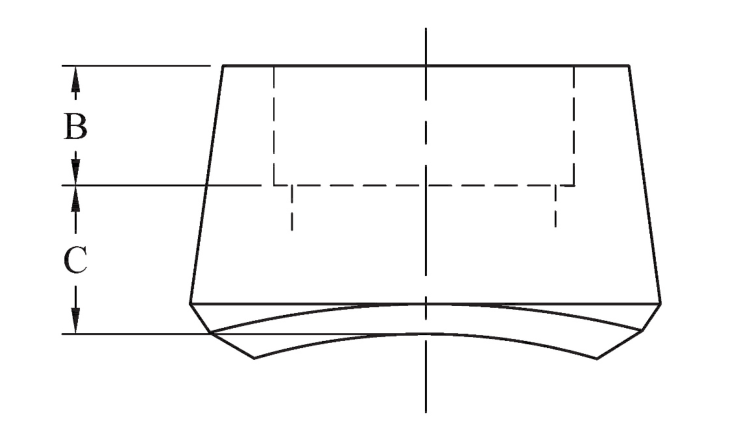

Dimension of Sockolet

90°A182 F22 Sockolet

| Dimensions in inches | ||||

| Outlet

(NPS) |

B Min. | C Max. | ||

| Class 3000 | Class 6000 | Class 9000 | ||

| 1/8 | 0.38 | 0.41 | 0.75 | |

| 1/4 | 0.38 | 0.41 | 0.75 | |

| 3/8 | 0.38 | 0.50 | 0.75 | |

| 1/2 | 0.38 | 0.63 | 0.94 | 0.94 |

| 3/4 | 0.50 | 0.63 | 1.00 | 1.00 |

| 1 | 0.50 | 0.88 | 1.13 | 1.13 |

| 1 1/4 | 0.50 | 0.88 | 1.19 | 1.19 |

| 1 1/2 | 0.50 | 0.94 | 1.25 | 1.25 |

| 2 | 0.62 | 0.94 | 1.44 | 1.44 |

| 2 1/2 | 0.62 | 1.00 | ||

| 3 | 0.62 | 1.19 | ||

| 4 | 0.75 | 1.19 | ||

| NOTE: (a)”B”Minimum Socket Depth per ASME B16.11 | ||||

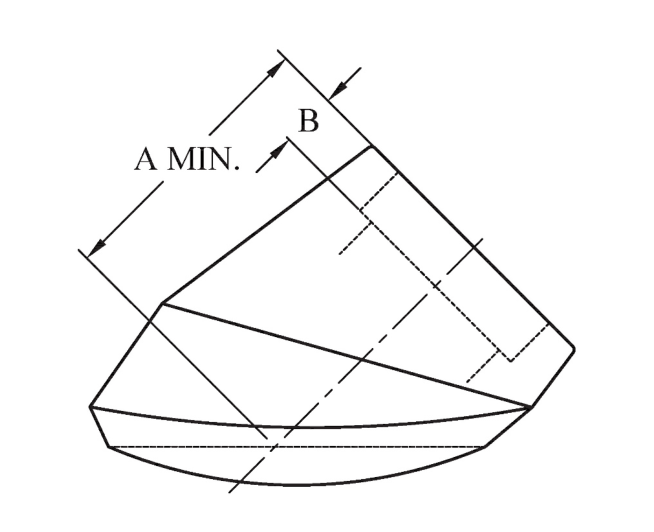

45°A182 F22 Sockolet

| Dimensions in inches | |||||

| Outlet

(NPS) |

BMin.(a) | A

(Top of Fitting to Run Pipe) |

|||

| Class 3000 | Class 6000 | ||||

| A Min. | A Max. | A Min. | A Max. | ||

| 1/4 | 0.38 | 1.50 | 1.69 | 1.53 | 1.88 |

| 3/8 | 0.38 | 1.50 | 1.69 | 1.53 | 1.88 |

| 1/2 | 0.38 | 1.50 | 1.75 | 1.81 | 2.19 |

| 3/4 | 0.50 | 1.81 | 2.00 | 2.13 | 2.50 |

| 1 | 0.50 | 2.13 | 2.50 | 2.41 | 2.88 |

| 1 1/4 | 0.50 | 2.41 | 3.00 | 2.56 | 3.06 |

| 1 1/2 | 0.50 | 2.50 | 3.00 | 3.09 | 3.38 |

| 2 | 0.62 | 3.00 | 3.31 | 3.09 | 4.13 |

| NOTE:(a)”B”Minimum Socket Depth per ASME B16.11 | |||||

Application fields

Petrochemical industry:

In the process of oil refining and chemical production, the pipeline system faces complex working conditions such as high temperature, high pressure, and strong corrosion. Alloy socket branch pipe seats are widely used in the branch connection of various process pipelines, such as the pipeline system in the hydrocracking unit and ethylene production unit of the refinery, which can meet the transportation requirements of different media (such as crude oil, refined oil, chemical raw materials, etc.) to ensure the safe and stable operation of the production process.

Power industry:

In thermal power plants and nuclear power plants, alloy socket branch pipe seats are used for the connection of steam-water pipelines, oil pipelines and other systems. For example, at the branch of the high-temperature and high-pressure steam pipeline in the thermal power plant, the alloy socket branch pipe seat can withstand the pressure and temperature changes of high-temperature steam to ensure the reliable distribution and transportation of steam; in the coolant pipeline system of the nuclear power plant, its good corrosion resistance and high strength ensure the sealing and safety of the pipeline system.

Papermaking industry:

The papermaking production process involves the transportation of a large amount of high-temperature, high-pressure, and corrosive media, such as cooking liquid, bleaching liquid, etc. Alloy socket branches can be used to connect various pipes in papermaking equipment. With its corrosion resistance and high strength, it ensures the normal operation of the pipeline system and reduces production interruptions and equipment damage caused by pipeline leakage.

Chemical and pharmaceutical industry:

In chemical and pharmaceutical production, pipelines need to transport various chemical raw materials and pharmaceutical solutions, and the sealing and corrosion resistance of pipeline connections are extremely high. Alloy socket branches can meet these strict requirements, ensure the quality control and environmental safety of the pharmaceutical production process, and prevent media leakage from affecting the quality of drugs and the production environment.