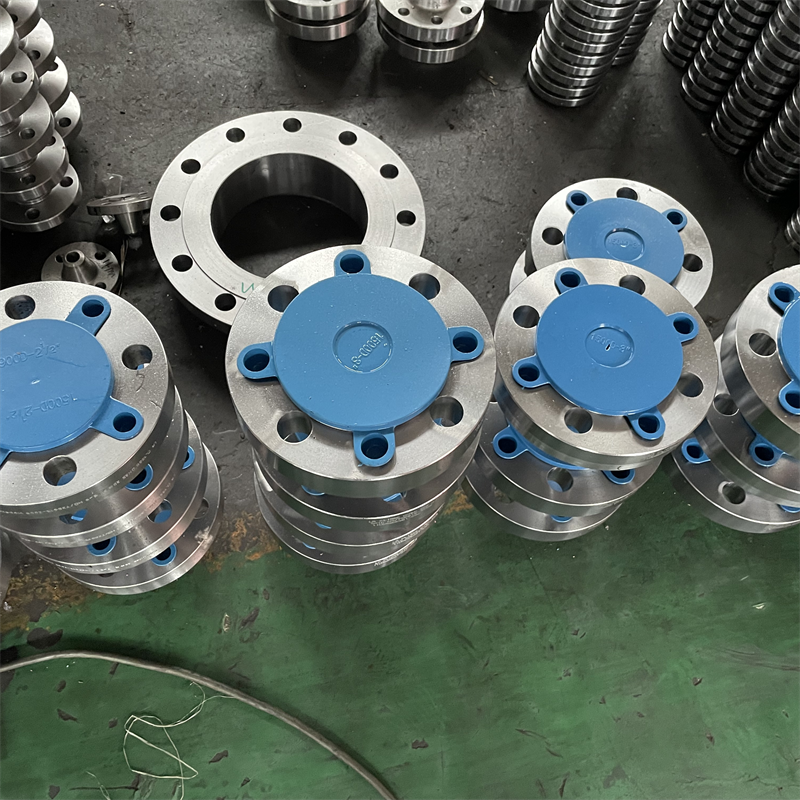

A182 F11 Socket Weld Flange

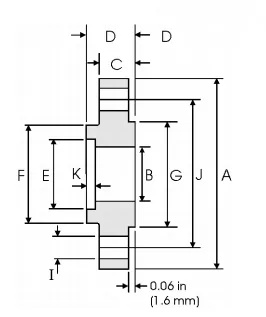

The connection method of A182 F11 socket flange is to insert the pipe into the socket of the flange, and then seal it with welding or use a sealing gasket. This connection method is relatively strong and can adapt to the thermal expansion and contraction of the pipe to a certain extent.

A182 is a standard specification of the American Society for Testing and Materials (ASTM). This standard covers the technical requirements of various forged or rolled alloy and stainless steel pipe flanges, forged fittings, valves and parts.

F11 is a grade in the A182 standard. The F11 grade material is usually a chromium-molybdenum alloy steel, and the design of this alloy composition gives the material good performance in high temperature and high pressure environments.

The connection method of A182 F11 socket flange is to insert the pipe into the socket of the flange, and then seal it with welding or use a sealing gasket. This connection method is relatively strong and can adapt to the thermal expansion and contraction of the pipe to a certain extent.