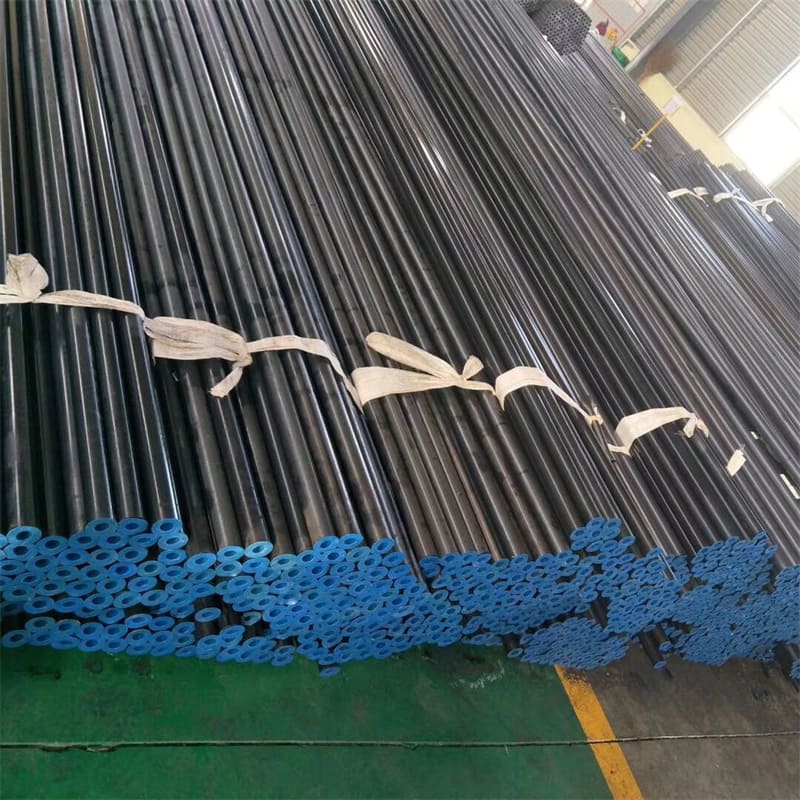

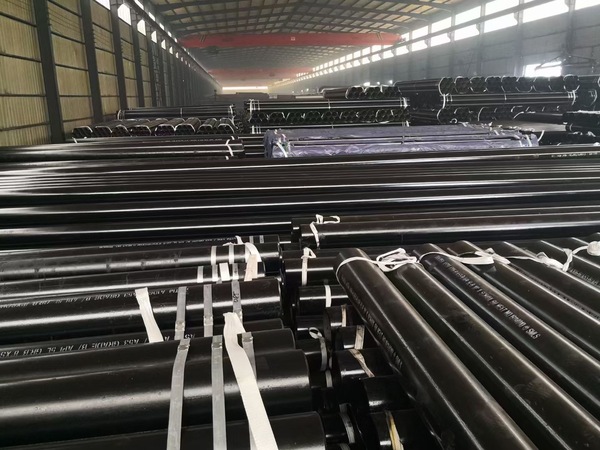

A106 GR B Seamless Steel Pipe

A106 seamless steel pipe is a seamless steel pipe produced in accordance with the American Society for Testing and Materials (ASTM) standard A106. This standard specifies the material, size, manufacturing process, mechanical properties and other requirements of steel pipes, aiming to ensure the quality and reliability of steel pipes in various industrial applications.

A106 seamless steel pipe is a seamless steel pipe produced in accordance with the American Society for Testing and Materials (ASTM) standard A106. This standard specifies the material, size, manufacturing process, mechanical properties and other requirements of steel pipes, aiming to ensure the quality and reliability of steel pipes in various industrial applications.

A106 seamless steel pipe is widely used in oil and natural gas pipelines. Due to its good corrosion resistance (to a certain extent, it can resist the corrosive components in oil and natural gas), high strength and sealing, it can ensure the safety and efficiency of oil and natural gas during long-distance transportation. In chemical production, it is used to transport various chemical raw materials and products. For example, when transporting acidic or alkaline chemical liquids, A106 seamless steel pipe can meet the corrosion resistance requirements through appropriate anti-corrosion treatment (such as coating or lining). It is used in pipeline projects such as water supply and drainage systems and heating systems in building structures. Its beautiful appearance and reliable performance make the pipeline system inside the building more durable and safe.

ASTM A106 Specification

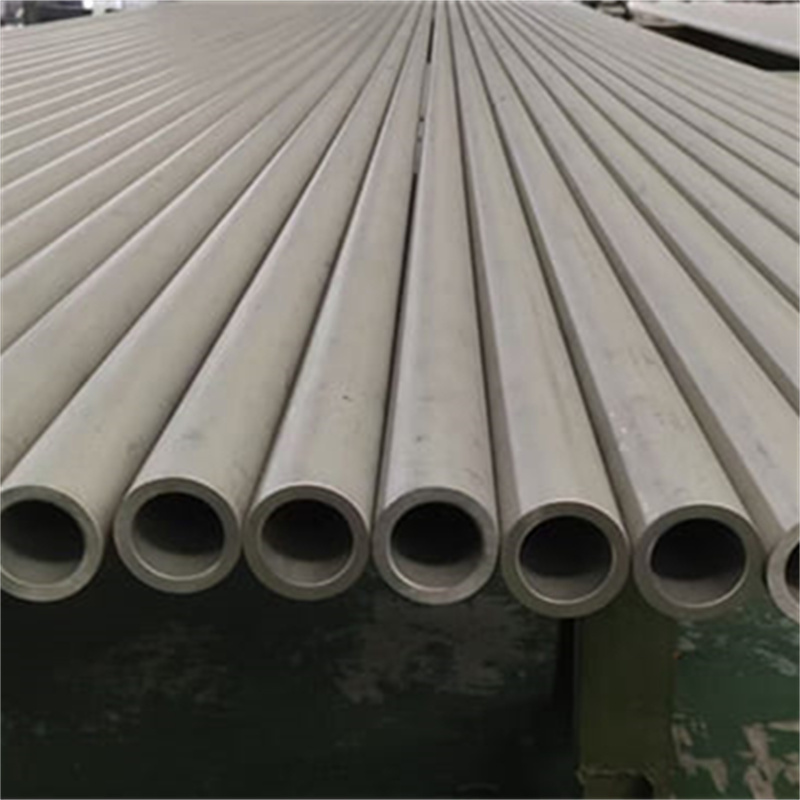

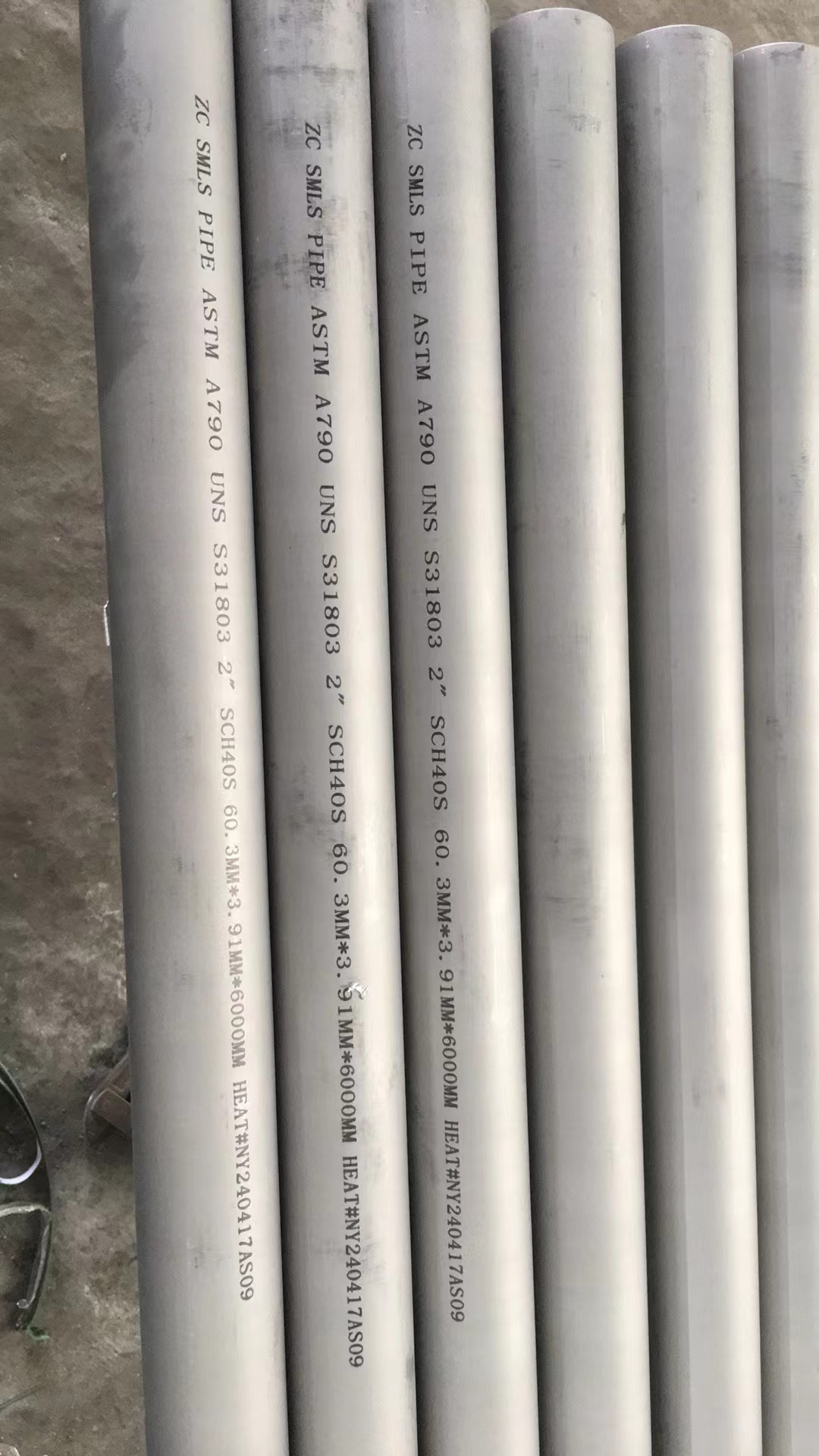

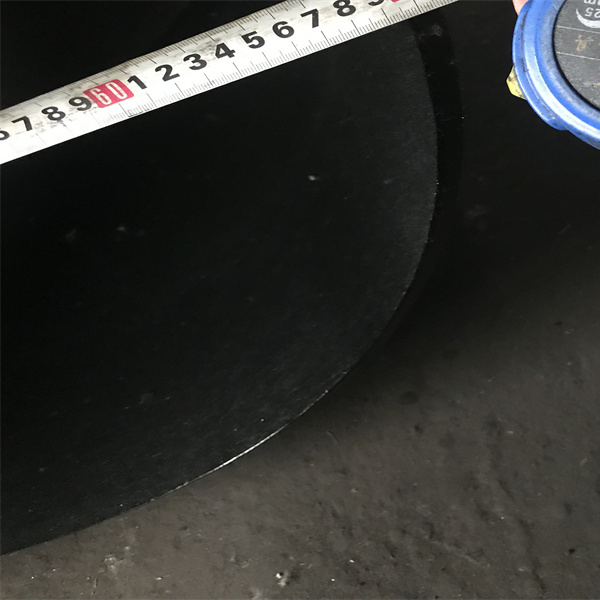

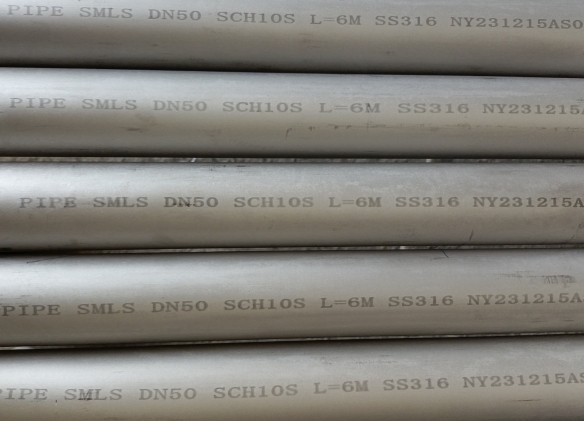

ASTM A106 carbon steel pipe specification is mainly applicable to seamless steel pipe size range of 1/8″ to 48″ (DN6 to DN1200). Wall thickness of these steel pipes must comply with ASME B36.10 standard.

| Processing Method | Seamless and Welded |

| Size Range | 1/8″- 48″ / DN6 – 1200 |

| Thickness Schedule | SCH 10, SCH 20, SCH 40, STD, XS, SCH 100, SCH 120, SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.10M |

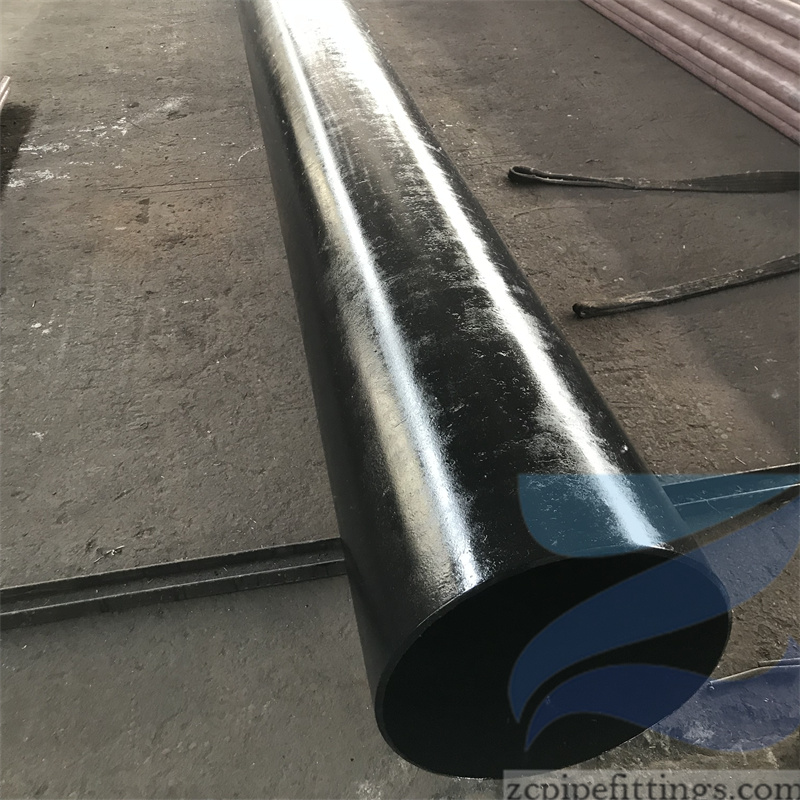

| Surface Treatment | Blasting and Painting , Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A106B / A53, API 5L B / X42 / 46 / 52 / 56 / 60 / 65 / 70, A333 GR 6 |

ASTM A106 Material Grade

Chemical composition

| CHEMICAL | LIMITS | C | Mn | P | S | Cu | Ni | Cr | Mo | V | Si |

| ASTM A106B | MIN | 0.29 | 0.10 | ||||||||

| MAX | 0.30 | 1.06 | 0.035 | 0.04 | 0.40 | 0.400 | 0.40 | 0.15 | 0.080 |

Mechanical properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A106 GR B | 415 min | 240 min | 22 min |

Galvanizing process of steel pipe

Hot-dip galvanizing process

Hot-dip galvanizing is a process in which a steel pipe is immersed in molten zinc liquid to form a zinc-iron alloy layer and a pure zinc layer on the surface of the steel pipe. The principle is based on the reaction of iron and zinc at high temperature. When the steel pipe is immersed in zinc liquid, the iron atoms on the surface of the steel pipe diffuse with the zinc atoms in the zinc liquid to form a metallurgically bonded zinc-iron alloy layer on the surface of the steel pipe, which has good adhesion and corrosion resistance. Subsequently, a purer zinc layer will be formed outside the alloy layer.

Electrogalvanizing process

Electrogalvanizing is a process of depositing a zinc layer on the surface of a steel pipe using the principle of electrolysis. The steel pipe is used as the cathode and the zinc plate is used as the anode, and is placed in an electrolyte containing zinc ions. When a DC power supply is turned on, the zinc ions are reduced to zinc atoms by electrons at the cathode (the surface of the steel pipe), thereby depositing a zinc layer on the surface of the steel pipe.