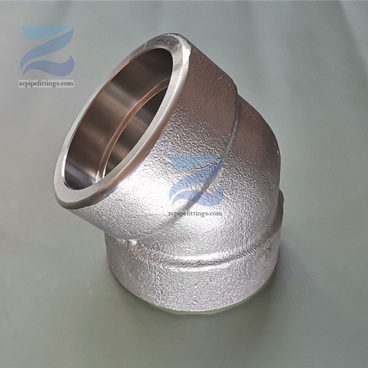

Home » Forged Steel Fittings » A105N Carbon Steel Socket Weld 90Degree Elbow

Content

What is Socket Weld 90 Degree Elbow?

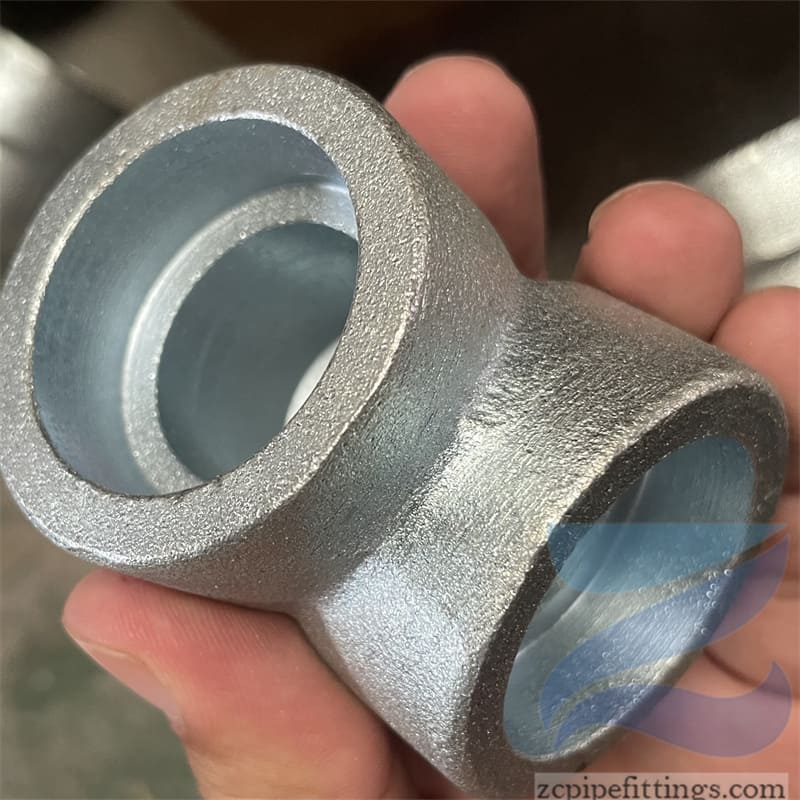

90 Degree Socket Weld Elbow makes 90° changes of course inside the extent of pipe to form a piping system. The way to associate the pipe is: arrange welding spine joints, hung joints and connection joints. Concurring to the era handle, it can be isolated into welding elbows, punching elbows, casting elbows, etc. A meddle fitting commonly utilized in the pipe foundation for the affiliation of a pipe bend. Socket Weld 90 Elbow is utilized to put through two pipes with the same apparent breadth to make the pipe turn 90 degrees.

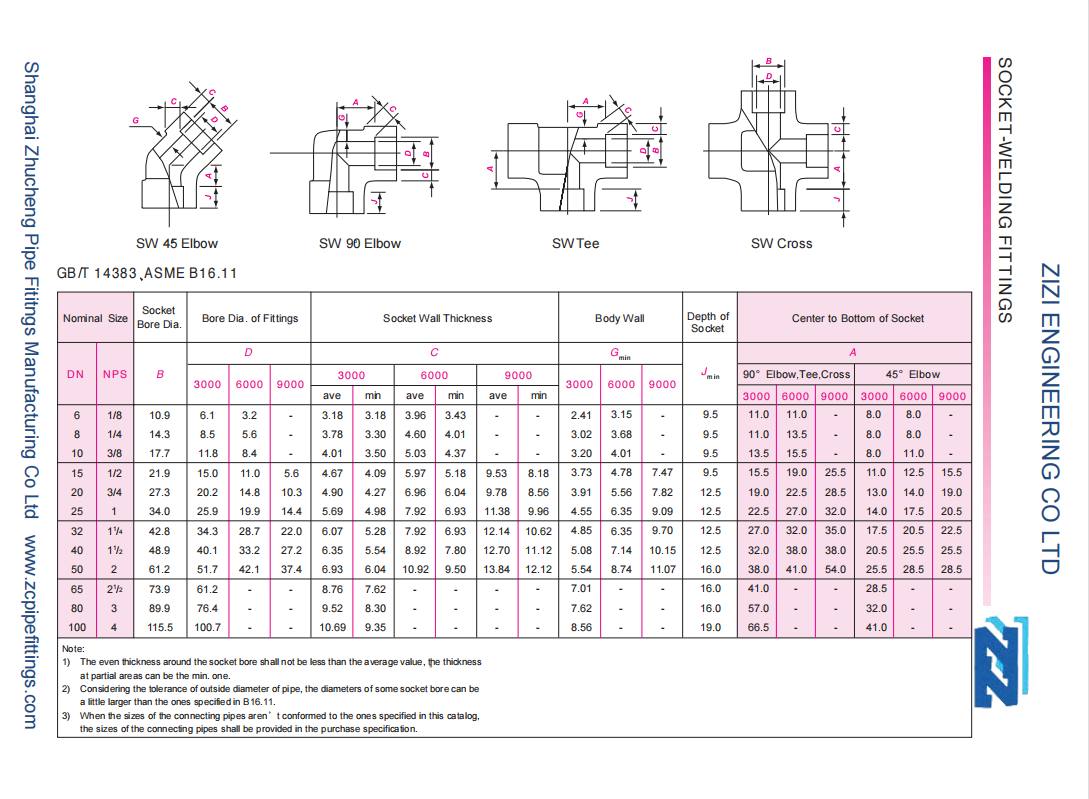

Specification of Socket Weld Fittings ASME B16.11

Inquiry

More Socket Weld Fittings