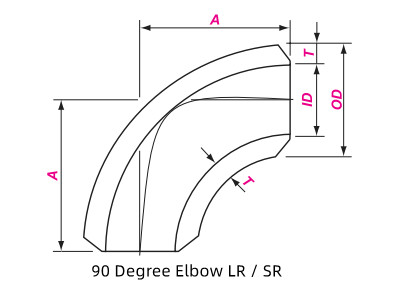

90° Butt Weld Elbow

90 Degree butt weld elbow is a pipe fitting with an angle of 90 degrees, which is mainly used to change the direction of the pipeline.

90 Degree butt weld elbow is a pipe fitting with an angle of 90 degrees, which is mainly used to change the direction of the pipeline. Butt welding refers to connecting the elbow and the pipeline by welding, which can provide higher strength and sealing. In the pipeline system, when the direction of the fluid needs to be changed vertically, the 90 degree butt welding elbow plays a key role.

Butt weld elbows are widely used in pipeline systems in industries such as construction, HVAC, chemical, petroleum, natural gas, pharmaceutical, automation and mechanical engineering. While providing a convenient connection method, it can also ensure that fluids and gases can flow smoothly in the pipeline and be transmitted in the specified direction.

Dimensions of Butt Weld Elbows

| DN | NPS | OD | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | 25 |

| 20 | 3/4 | 26.7 | 38 | 25 |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1-1/4 | 42.2 | 48 | 32 |

| 40 | 1-1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2-1/2 | 73.0 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3-1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273.0 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 550 | 22 | 559.0 | 838 | 559 |

| 600 | 24 | 610.0 | 914 | 610 |

key Characteristics and Applications

Applications:

These elbows are widely used in various industries, including oil and gas, chemical processing, power generation, and plumbing.

They are suitable for high-pressure and high-temperature applications due to the strength of the welded connection.

Materials:

90° butt weld elbows are available in a variety of materials, including carbon steel, stainless steel, and alloy steel, depending on the application and the fluid being transported.

Types:

They come in different radius types, most commonly:

Long radius: The radius of the bend is 1.5 times the pipe diameter. This reduces friction and pressure drop.

Short radius: The radius of the bend is equal to the pipe diameter. This is used where space is limited.

Advantages:

Strong and durable connections.

Suitable for high-pressure and high-temperature environments.

Provides a smooth flow path, especially with long radius elbows.