ASTM A403 UNS S31254 Pipe Fittings

ASTM A403 UNS S31254 pipe fittings are a specific grade of stainless steel belonging to the austenitic category. It is also known by the trade name “6Mo” and provides excellent corrosion resistance in extremely harsh environments, including those containing chlorides, acids and other corrosives.

ASTM A403 UNS S31254 pipe fittings are a specific grade of stainless steel belonging to the austenitic category. It is also known by the trade name “6Mo” and provides excellent corrosion resistance in extremely harsh environments, including those containing chlorides, acids and other corrosives. This makes it particularly suitable for applications in industries such as chemical processing, petrochemicals, oil and gas, and marine.

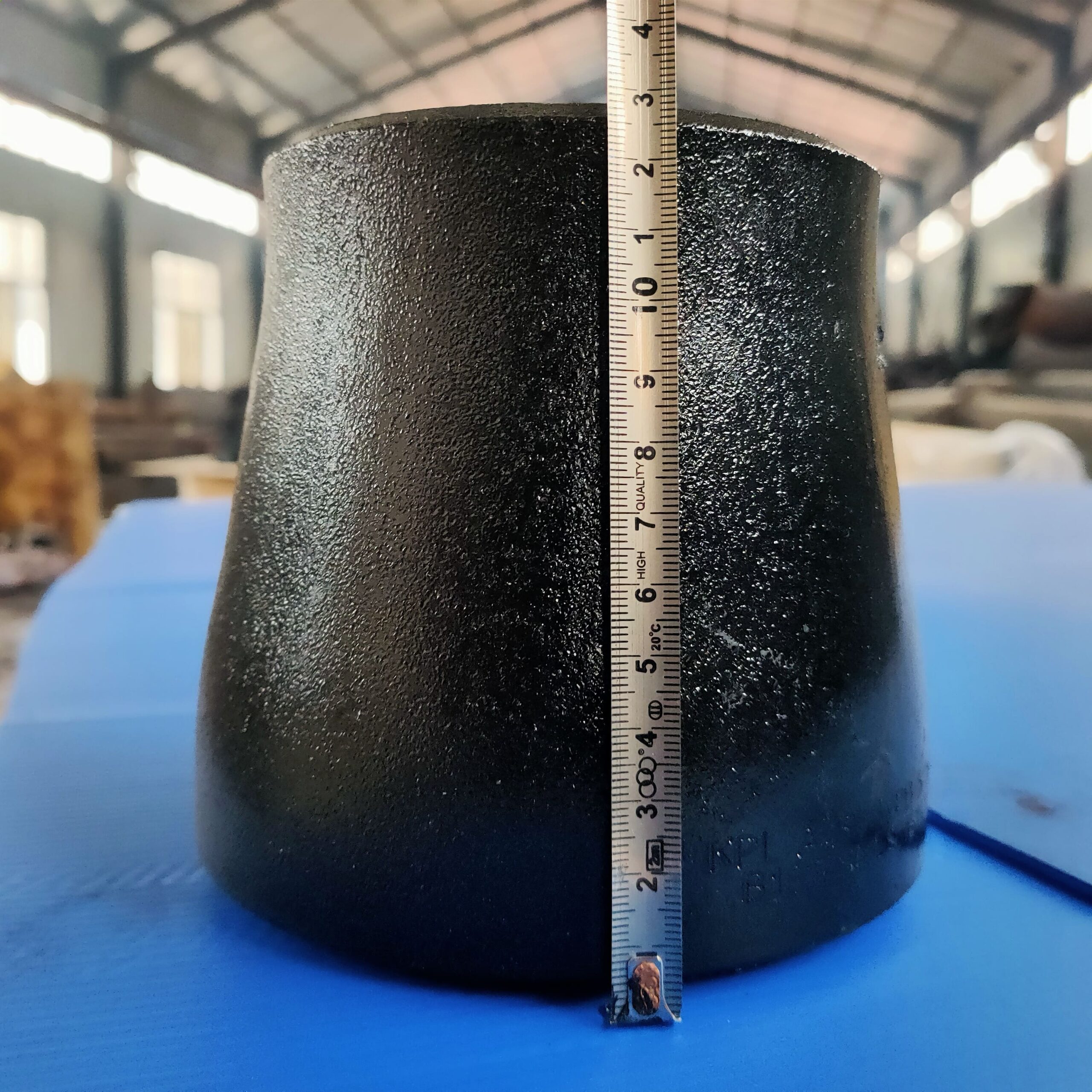

This is a standard specification for wrought austenitic stainless steel pipe fittings developed by the American Society for Testing and Materials (ASTM). The standard covers various types of pipe fittings, such as elbows, tees, caps, etc., and specifies the dimensions, tolerances, material requirements, manufacturing processes, inspection methods, and marking, packaging, etc. of these pipe fittings to ensure that the quality and performance of the pipe fittings meet the relevant requirements.

UNS is a numbering system for identifying metals and alloys, and ASTM A403 UNS S31254 pipe fittings are a specific number for super austenitic stainless steel. This stainless steel has excellent corrosion resistance and performs especially well in harsh corrosive environments.

ASTM A403 UNS S31254 pipe fittings specifications

| Material | ASTM A403 / ASME SA403 |

| Dimension | Seamless Butt Weld Fittings : 1/2″ – 10″ |

| Welded Butt Weld Fittings : 1/2″ – 48″ | |

| Standard | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Wall Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

Material Analysis of ASTM A403 UNS S31254

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| UNS S31254(SMO 254) | MIN | 17.5 | 19.5 | 6 | 0.18 | 0.5 | |||||

| MAX | 0.02 | 1 | 0.03 | 0.01 | 0.8 | 18.5 | 20.5 | 6.5 | 0.25 | 1 |

Chromium (Cr): 19.5 – 20.5%

Chromium is one of the most important alloying elements in stainless steel. It can form a dense oxide film on the surface of steel, which plays a protective role and prevents steel from being corroded. In S31254, the higher chromium content makes it have good corrosion resistance, especially in oxidizing media.

Nickel (Ni): 17.5 – 18.5%

Nickel can improve the toughness, strength and corrosion resistance of steel, especially in acidic environment and high temperature environment, the presence of nickel can enhance the corrosion resistance of steel. At the same time, nickel can also improve the processing and welding properties of steel.

Molybdenum (Mo): 6.0 – 6.5%

Molybdenum is an effective anti-corrosion element that can significantly improve the corrosion resistance of steel in reducing media. For example, in a solution containing chloride ions, molybdenum can prevent pitting and crevice corrosion of steel.

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| UNS S31254(SMO 254) | 650 min | 300 min | 35 min | 50 min |

Tensile strength: ≥ 650 MPa

Tensile strength refers to the maximum stress value that a material can withstand in a tensile test. The high tensile strength of ASTM A403 UNS S31254 pipe fittings enables them to withstand large tensile loads and is suitable for some occasions with high strength requirements, such as high-pressure pipeline systems, chemical equipment, etc.

Yield strength: ≥ 300 MPa

Yield strength is the stress value when the material begins to undergo obvious plastic deformation. A higher yield strength indicates that S31254 can maintain good elastic deformation capacity when subjected to a certain load, is not prone to excessive deformation, and ensures the stability and safety of the pipe fittings during use.

Advantages of ASTM A403 UNS S31254 Pipe Fittings

The advantages of ASTM A403 UNS S31254 pipe fittings are mainly reflected in the following aspects:

Excellent corrosion resistance

ASTM A403 UNS S31254 pipe fittings belong to super austenitic stainless steel with excellent corrosion resistance.

Good mechanical properties

ASTM A403 UNS S31254 pipe fittings not only have excellent corrosion resistance, but also have good mechanical properties.

Wide range of applications

Due to the excellent corrosion resistance and good mechanical properties of ASTM A403 UNS S31254 pipe fittings, its application range is very wide.

Reliable quality assurance

The production and inspection of ASTM A403 UNS S31254 pipe fittings follow strict standards and specifications.

In summary, ASTM A403 UNS S31254 pipe fittings have the advantages of excellent corrosion resistance, good mechanical properties, a wide range of applications and reliable quality assurance. These advantages make it play an important role in various industrial piping systems and make positive contributions to industrial progress and social development.