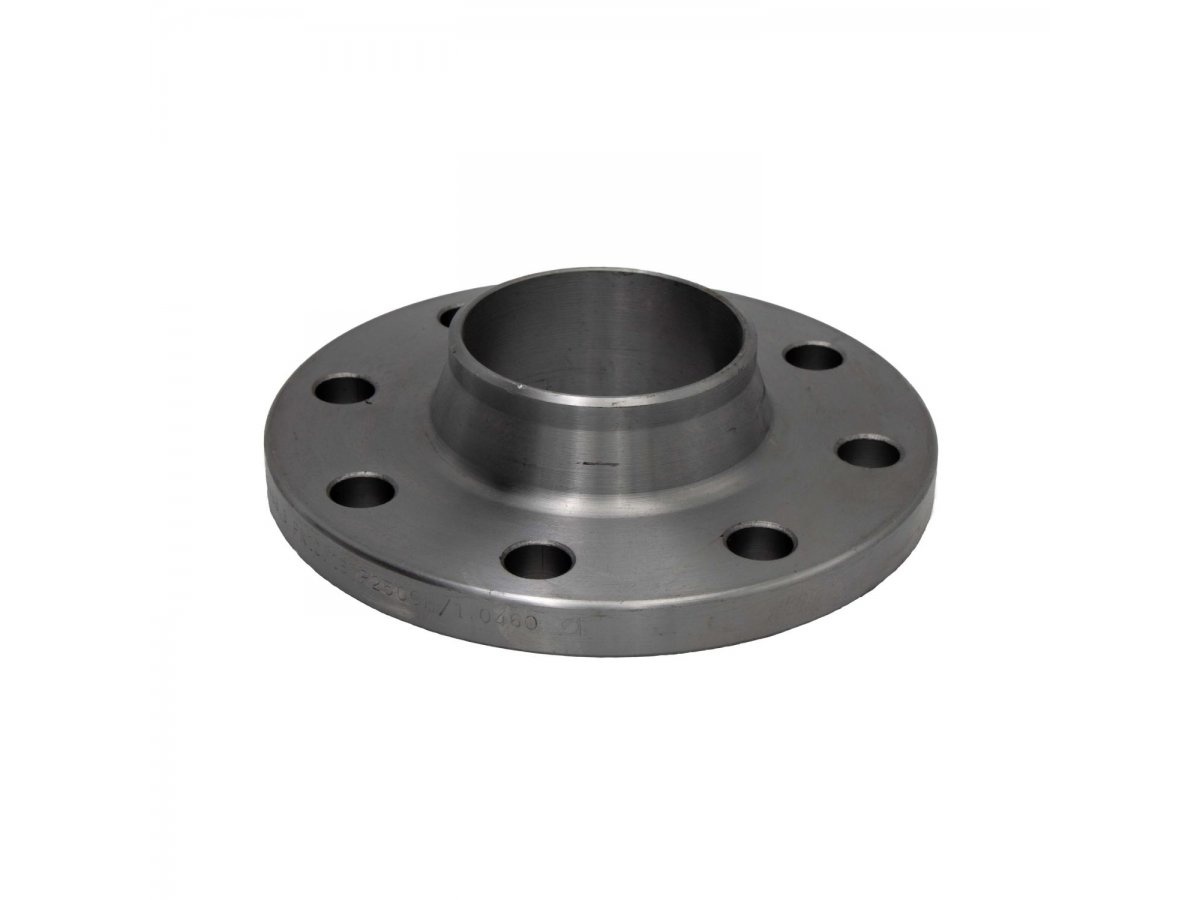

ASTM A182 Weld Neck Flange

ASTM A182 weld neck Flanges are made up of different stainless steel materials. There are different grades to the stainless steel depending on the material composition and the mechanical properties vary.

ASTM A182 weld neck Flanges are made up of different stainless steel materials. There are different grades to the stainless steel depending on the material composition and the mechanical properties vary.

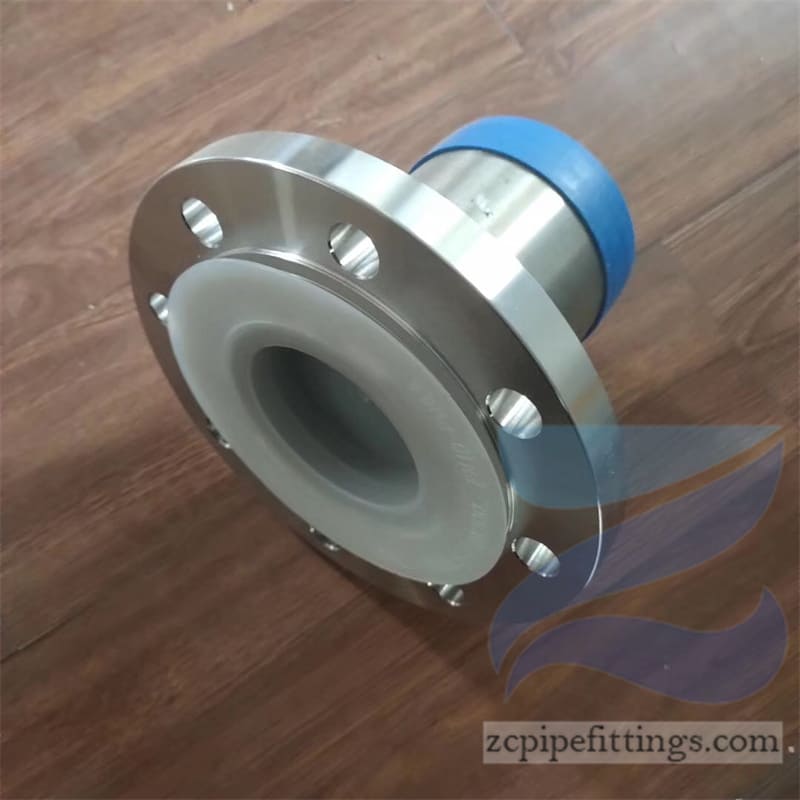

The ASTM A182 Weld Neck Flange are made up of a super austenitic material that has good corrosion resistant properties with low carbon in its composition. The applications include utility scrubber assemblies. The flanges are also used in acid production and fertilizer production plants due to its corrosion resistance.

Specification of ASTM A182 Weld Neck Flange

| Shape Type | Regular and Long Neck |

| Sealing Face | RF, FF, FTJ |

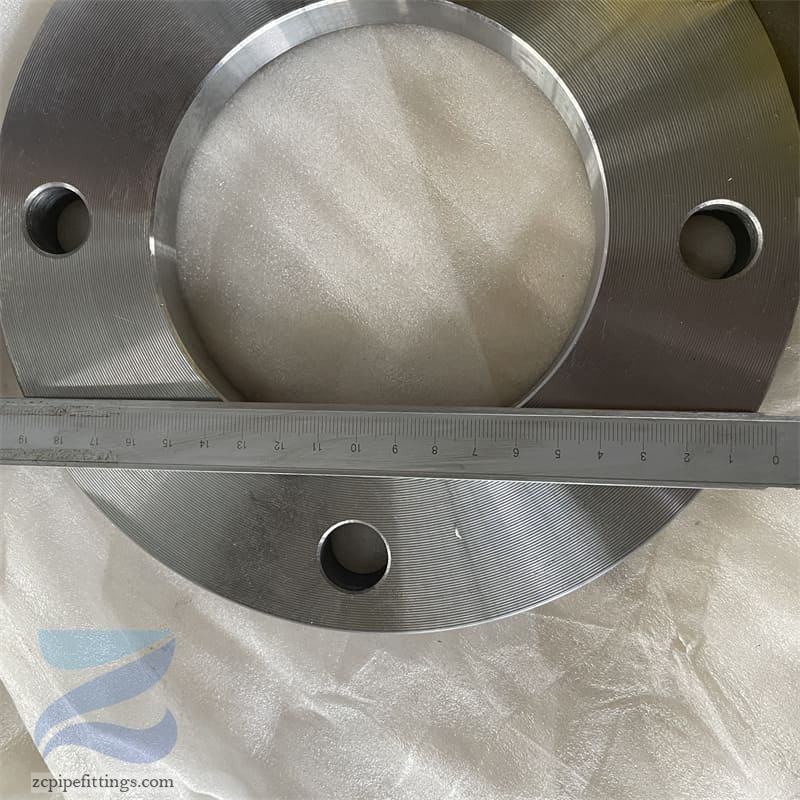

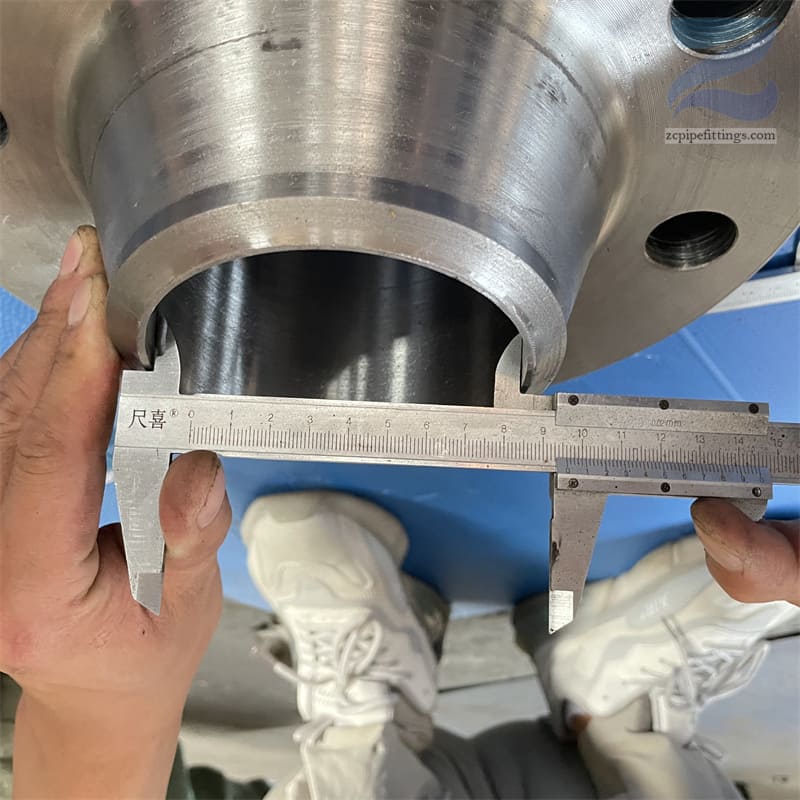

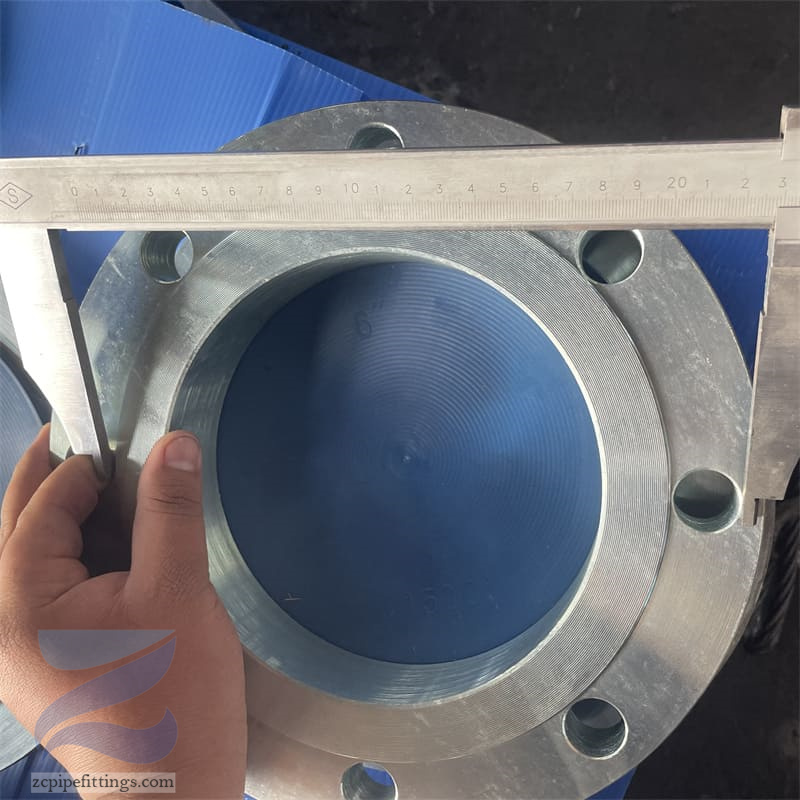

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ASME B16.5, ASME B16.47 Series A/B |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

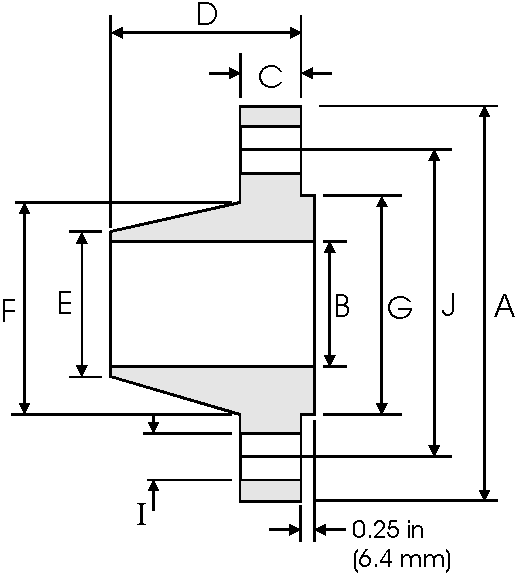

Class 600 Weld Neck Flange Dimension

| Nominal Pipe Size |

A | B | C | D | E | F | G | H | I | J | Weight | |

| mm | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg/ piece |

|

| 1/2 | 21.30 | 95.30 | specified by Purchaser |

14.20 | 52.30 | 21.30 | 38.10 | 35.00 | 4 | 15.70 | 66.55 | 0.87 |

| 3/4 | 26.70 | 117.3 | 15.70 | 57.15 | 26.70 | 47.80 | 42.90 | 4 | 19.10 | 82.60 | 1.45 | |

| 1 | 33.40 | 124.0 | 17.50 | 62.00 | 33.50 | 53.80 | 50.80 | 4 | 19.10 | 88.90 | 1.76 | |

| 11/4 | 42.20 | 133.4 | 20.60 | 66.55 | 42.20 | 63.50 | 63.50 | 4 | 19.10 | 98.60 | 2.49 | |

| 11/2 | 48.30 | 155.4 | 22.40 | 69.85 | 48.30 | 69.85 | 73. 15 | 4 | 22.40 | 114.3 | 3.49 | |

| 2 | 60.30 | 165. 1 | 25.40 | 73.15 | 60.45 | 84.10 | 91.90 | 8 | 19.10 | 127.0 | 4.36 | |

| 21/2 | 73.00 | 190.5 | 28.40 | 79.25 | 73.15 | 100.1 | 104.6 | 8 | 22.40 | 149.4 | 6.43 | |

| 3 | 88.90 | 209.6 | 31.75 | 82.60 | 88.90 | 117.3 | 127.0 | 8 | 22.40 | 168.1 | 8.53 | |

| 31/2 | 101.6 | 228.6 | 35.10 | 85.90 | 101.6 | 133.4 | 139.7 | 8 | 25.40 | 184.2 | 10.7 | |

| 4 | 114.3 | 273. 1 | 38.10 | 101.6 | 114.3 | 152.4 | 157.2 | 8 | 25.40 | 215.9 | 17.4 | |

| 5 | 141.3 | 330.2 | 44.50 | 114.3 | 141.2 | 189.0 | 185.7 | 8 | 28.40 | 266.7 | 29.2 | |

| 6 | 168.3 | 355.6 | 47.80 | 117.3 | 168.4 | 222.3 | 215.9 | 12 | 28.40 | 292.1 | 34.9 | |

| 8 | 219.1 | 419. 1 | 55.60 | 133.4 | 219.2 | 273.1 | 269.7 | 12 | 31.75 | 349.3 | 53.9 | |

| 10 | 273.0 | 508.0 | 63.50 | 152.4 | 273.0 | 342.9 | 323.8 | 16 | 35.10 | 431.8 | 86.5 | |

| 12 | 323.8 | 558.8 | 66.55 | 155.4 | 323.8 | 400.1 | 381.0 | 20 | 35.10 | 489.0 | 103 | |

| 14 | 355.6 | 603.3 | 69.85 | 165.1 | 355.6 | 431.8 | 412.7 | 20 | 38.10 | 527.1 | 122 | |

| 16 | 406.4 | 685.8 | 76.20 | 177.8 | 406.4 | 495.3 | 469.9 | 20 | 41.10 | 603.3 | 170 | |

| 18 | 457.2 | 743.0 | 82.60 | 184.2 | 457.2 | 546.1 | 533.4 | 20 | 44.50 | 654.1 | 204 | |

| 20 | 508.0 | 812.8 | 88.90 | 190.5 | 508.0 | 609.6 | 584.2 | 24 | 44.50 | 723.9 | 254 | |

| 24 | 609.6 | 939.8 | 101.6 | 203.2 | 609.6 | 717.6 | 692.1 | 24 | 50.80 | 838.2 | 358 |

Advantages of ASTM A182 Weld Neck Flange

A182 weld neck flange is a widely used pipe connector. It is produced based on ASTM A182 standard and connected to the pipe by butt welding process. This flange has many advantages:

– High-quality alloy material

– High strength and good toughness

– Welding performance advantage

– Butt welding process advantage

– Welding adaptability

– Corrosion resistance advantage

– Good corrosion resistance

– Customizable corrosion resistance

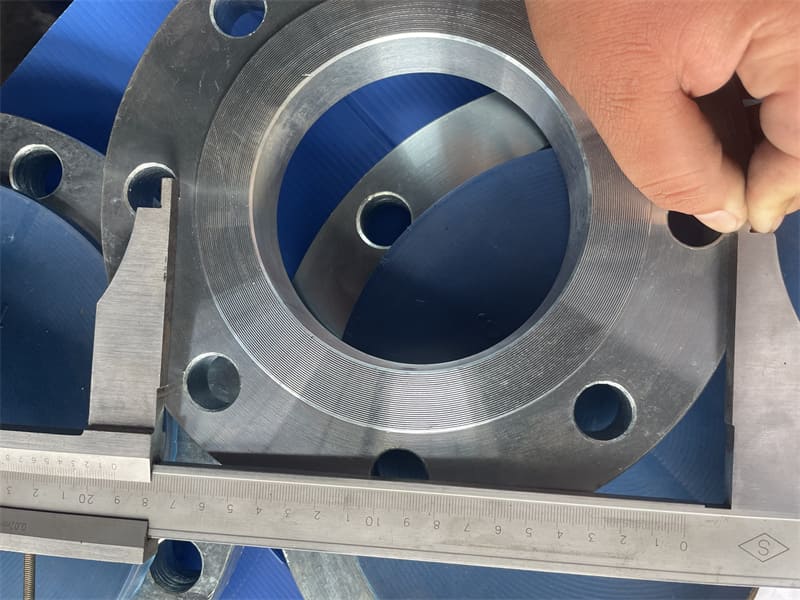

– Size and precision advantage

– Strict size standards

– Precise processing accuracy

– Application range advantage

– Wide temperature applicability