90 Degree Carbon Steel Elbow

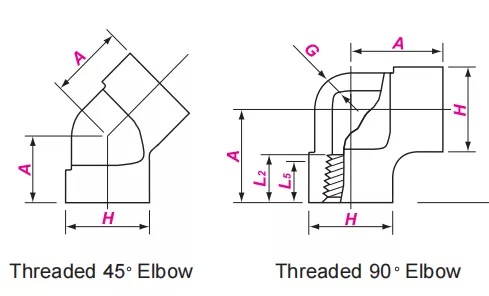

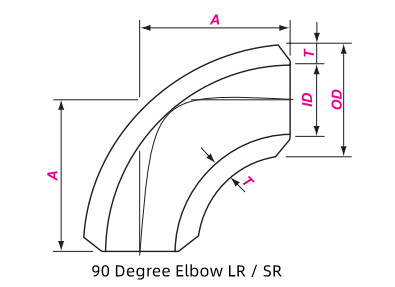

90 Degree Carbon steel elbow is a pipe fitting with a 90 degree bending angle. It connects two pipes and changes the direction of the pipes at right angles, ensuring that the fluid flows along a predetermined path in the pipe system.

90 Degree Carbon steel elbow is a pipe fitting with a 90 degree bending angle. It connects two pipes and changes the direction of the pipes at right angles, ensuring that the fluid flows along a predetermined path in the pipe system.

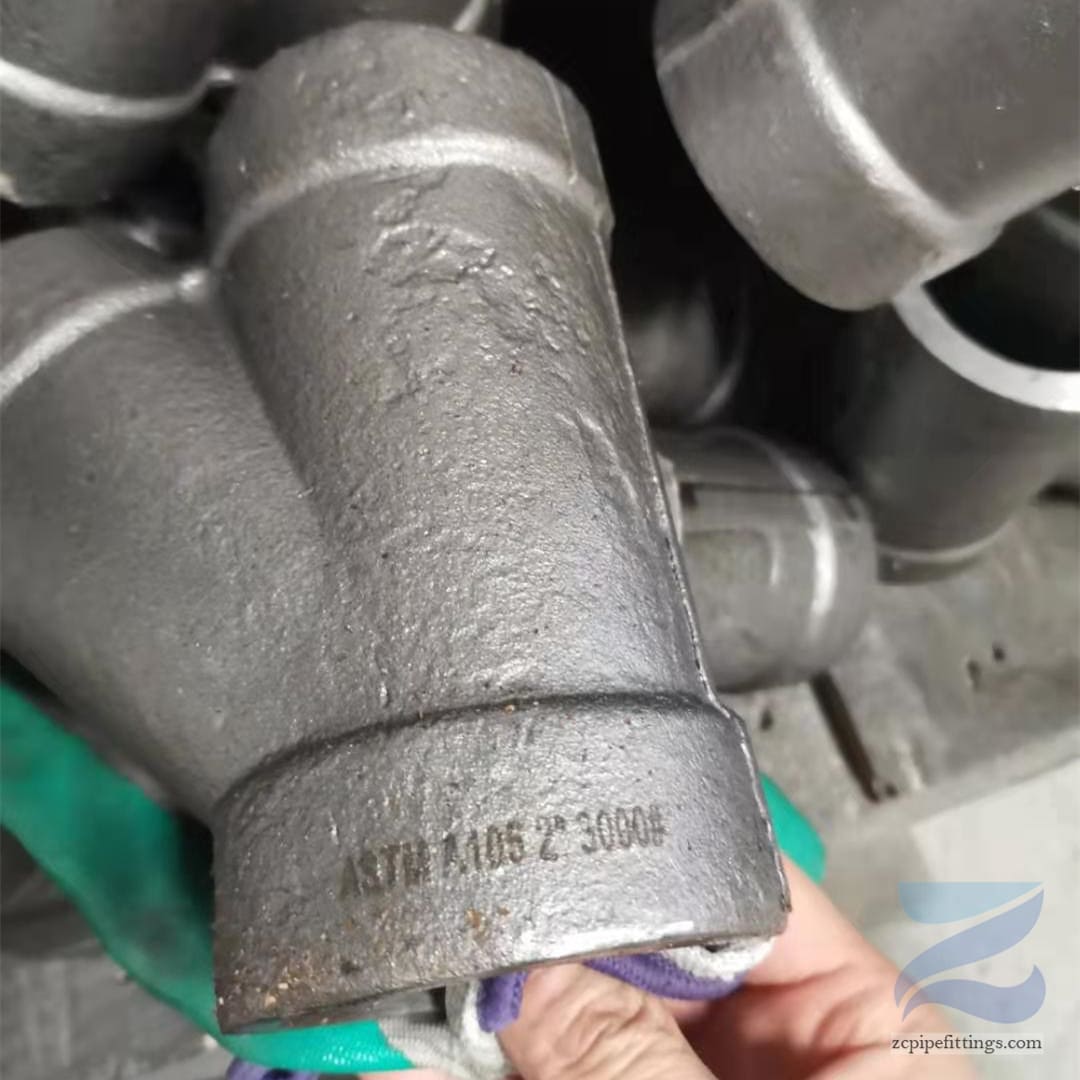

Carbon steel material itself has high strength and can withstand greater pressure and weight. In high-pressure pipeline systems, carbon steel 90-degree elbows can ensure the safe operation of pipelines and prevent elbows from breaking or deforming due to excessive pressure. Carbon steel has good high temperature resistance and can maintain its mechanical properties stable within a certain temperature range.