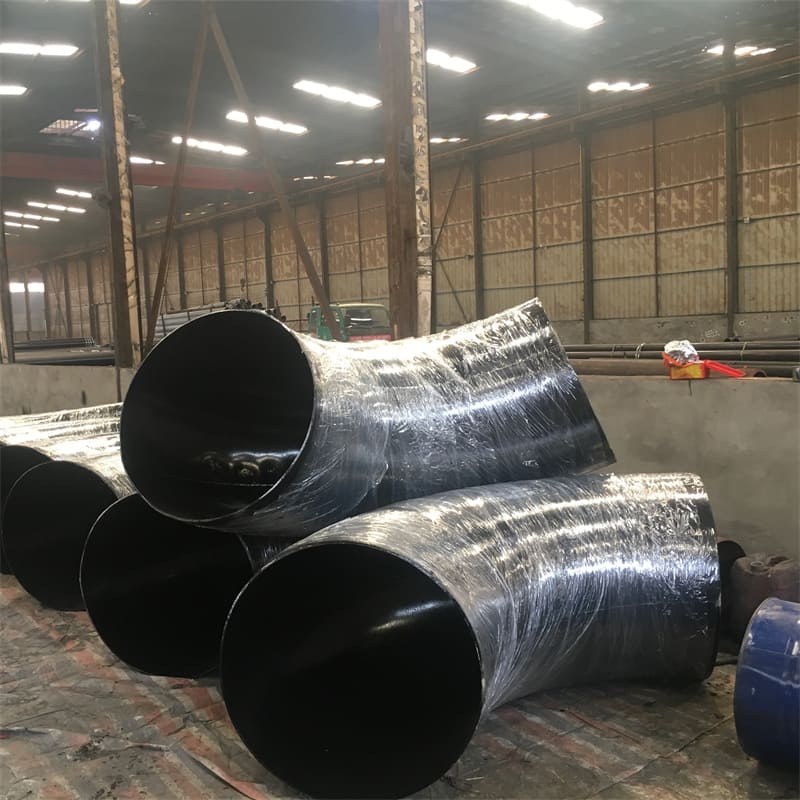

Concept of 90 Deg BW elbow

90 degree elbow is one type of steel pipe fittings which used to change direction of the pipeline.It can be divided into long radius (LR) and short radius (SR). We provide carbon steel, stainless steel and aluminum elbow for the overseas projects.

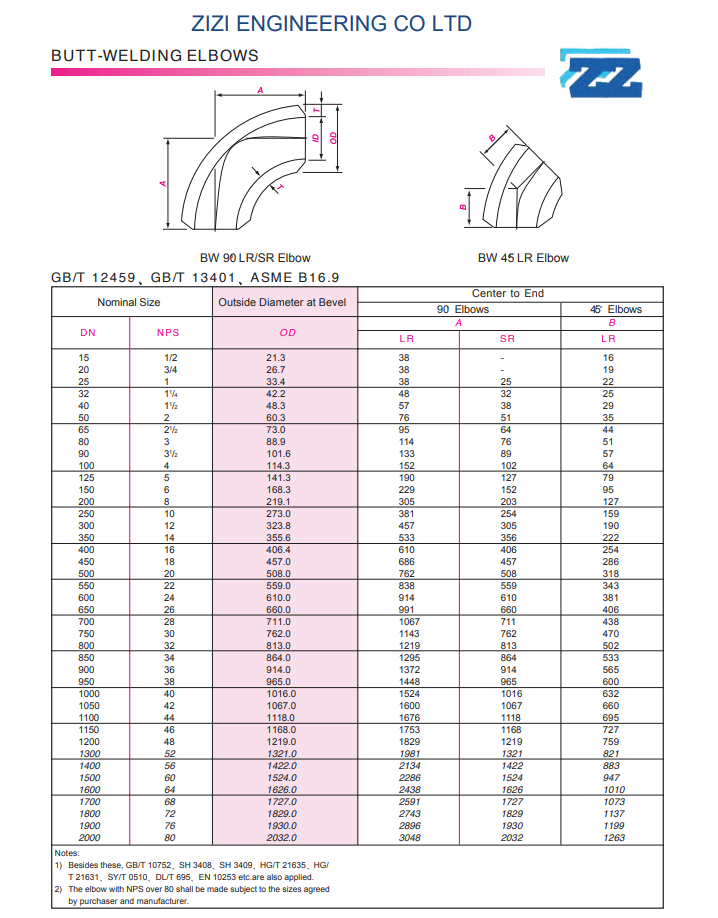

Specifications

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| Bending Radius | Long Radius (LR) and Short Radius (SR) |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Applications

Butt weld elbow is a steel elbow formed by hot pressing or forging. Its connection form is to directly weld the elbow and steel pipe. Butt welded elbows are mainly used for elbow with higher pressure and temperature than other connection types (socket welded elbow or threaded pipe elbow).

Buttwelding Fittings are used in a piping system to change direction or function of media, to branch off, reduce pipe size or attach auxiliary equipment. They are availbale in multiple types as elbow, tee, cap, reducer, stub end and oelt, that produced in cold and hot forming based on ASTM A403 and ASTM A234 specification.