90 Deg Elbow High Pressure Pipe Fittings

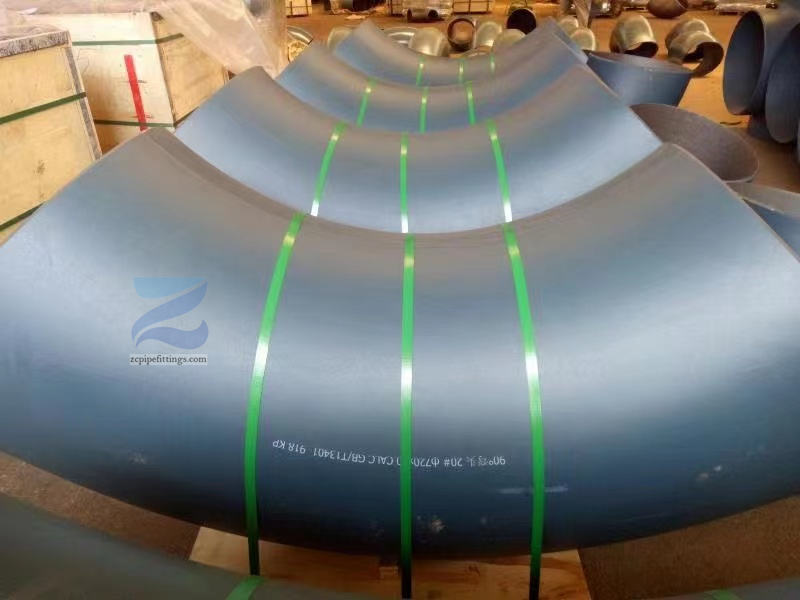

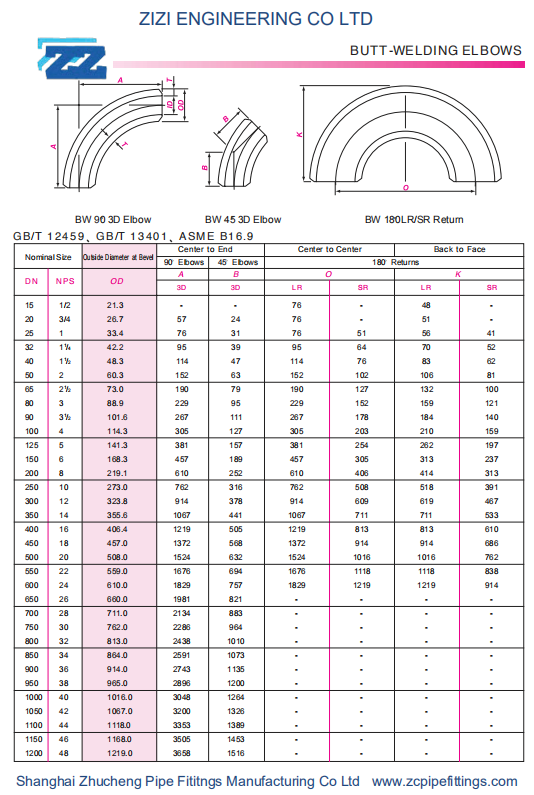

According to fluid flow direction of the pipes, elbows can be divided into different degrees, such as 45 degree, 90 degree, 180 degree, which are most common elbows. Also there are 60 degree and 120 degree elbows for some special pipelines. This degree is just an representation of the angle by which the fluid flow is going to change after flowing through the said elbow.

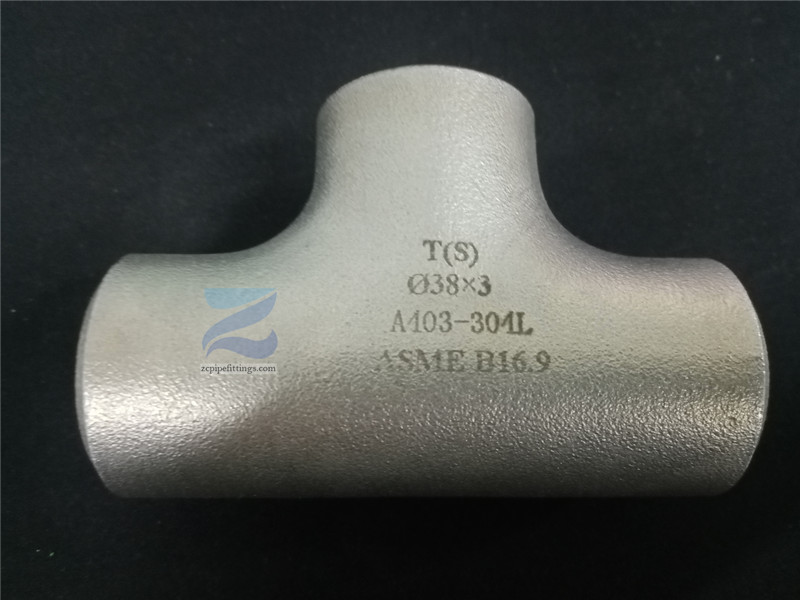

90 degree steel pipe elbow functioned to change fluid direction by 90 degree, so also named as vertical elbow.At the same time, it is divided into long radius elbow and short radius elbow.LR 90 degree steel pipe elbow are installed between different lengths pipe or tubing. It helps to change direction at 90 degree, and is commonly used to connect hoses to pumps, deck drains and valve.SR 90 degree elbow is the same as the pipe elbow mentioned above, but the diameter is shorter. Therefore, this kind of steel elbow is often used when space is not enough.A 90 degree elbow attaches readily to plastic, copper, cast iron, steel and lead. It can also attach to rubber with stainless steel clamps. Available in many materials like silicon, rubber compounds, galvanized steel etc.

Product features

- ReliableLightweight

- High tensile strength

- Weldability

- Excellent corrosion resistance

- Resistance to oxidation

| Shape | Elbow, Tee, Cross, Bend, Reducer, Cap, Stub End |

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Applications

- Petroleum

- Chemical

- Power

- Gas

- Metallurgy

- shipbuilding