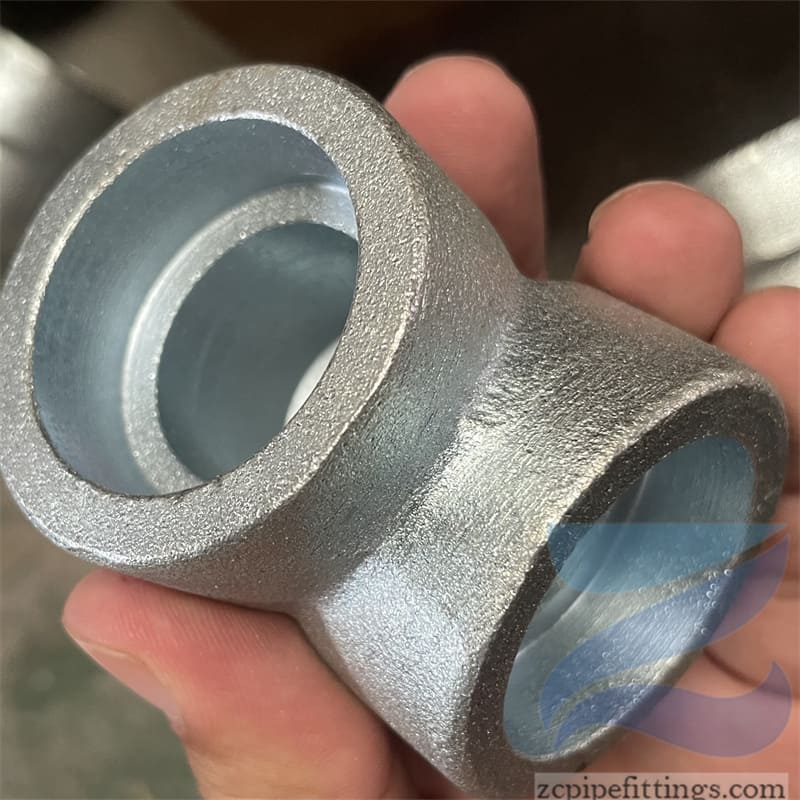

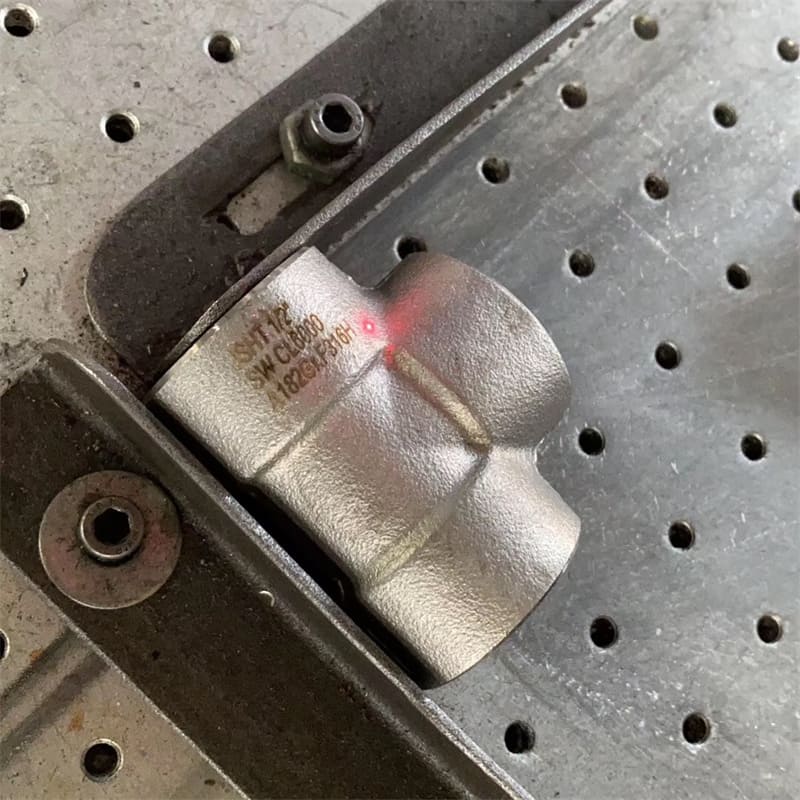

4IN 3000PSI ASTM A105 Socket Weld Tee

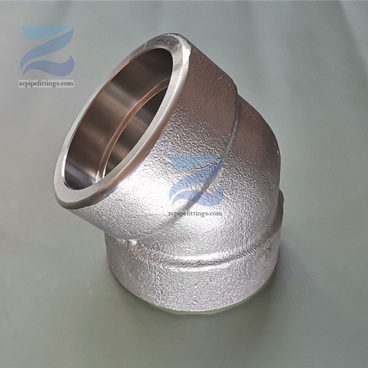

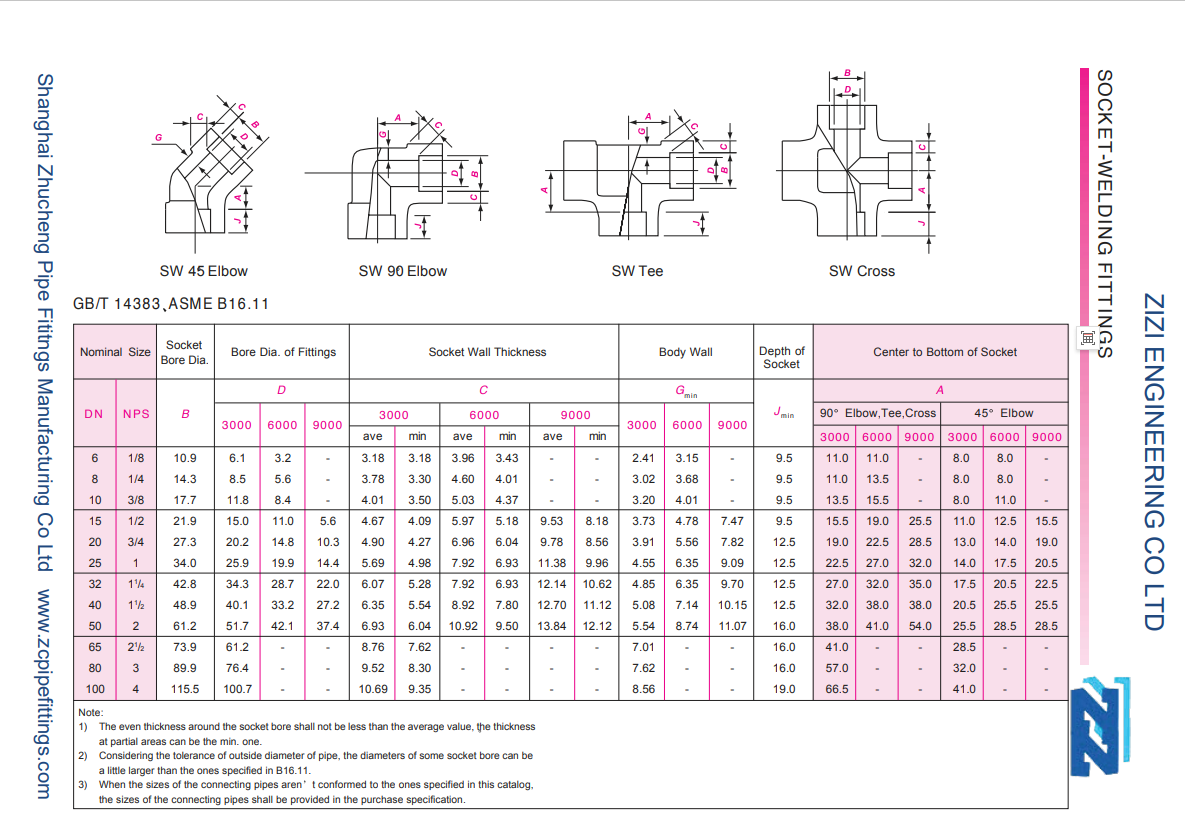

Socket weld pipe fittings is a family member of forged steel fittings, which used for small bore pipes and piping systems (generally below 4 inches). We usually manufacture them according to ASME B16.11 standard.

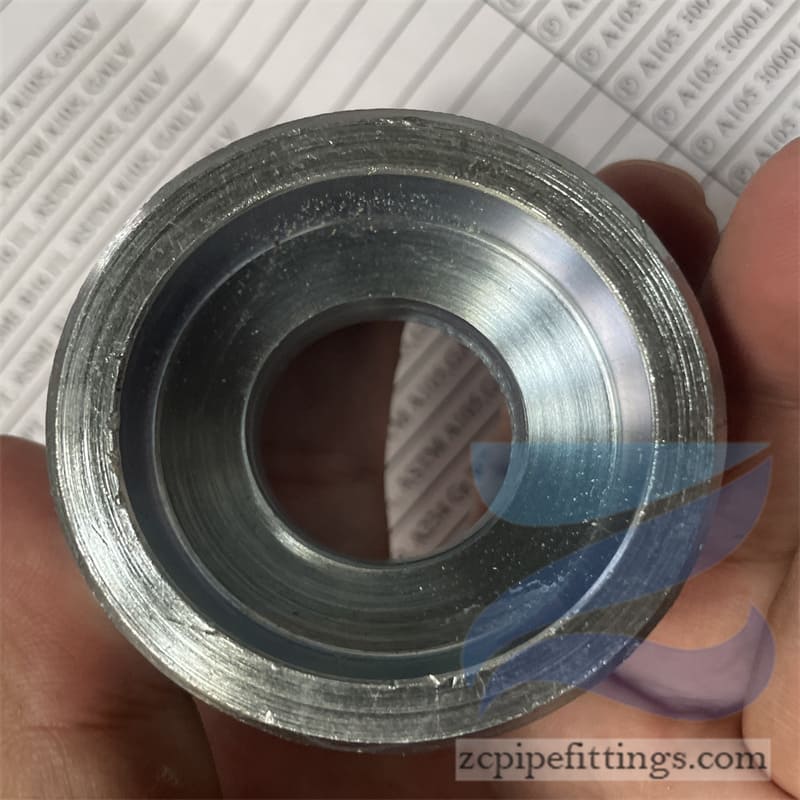

4IN 3000PSI ASTM A105 Socket Weld Tee is used for welding pipes and fittings including reducers, tees and elbows. Socket weld pipe fittings are used to permanently join pipes that are inserted into a recess in the fitting, flange or valve. Once correctly inserted, fillet type sealing welds are applied to join the pipe to the fitting. A socket weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a valve, fitting or flange. In contrast to buttweld fittings, socket weld fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller. To join pipe to valves and fittings or to other sections of pipe, fillet-type seal welds be used. Socket-welded joints construction is a good choice wherever the benefits of high leakage integrity and great structural strength are important design considerations. Fatigue resistance is lower than that in butt-welded construction due to the use of fillet welds and abrupt fitting geometry, but it is still better than that of most mechanical joining methods.

| Shape | Elbow, Tee, Cross, Coupling, Union, Cap, Reducing Insert, Sockolet |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Some details of Socket Weld fittings

SW Fittings are family of high pressure fittings are used in various industrial processes.

They are used for lines conveying flammable, toxic or expensive material where no leakage can be permitted, and for steam 300 to 600 PSI.

They are used only in conjunction with ASME Pipe and are available in the same size range.

They are used in areas where pipe-work is permanent and are designed to provide good flow characteristics.

They are are produced to several ASTM standards and are manufactured in accordance with ASME B16.11. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, marking, and material requirements for forged carbon and alloy steel. Acceptable material forms are forgings, bars, seamless pipe, and seamless tubes which conform to the fittings chemical requirements, melting practices, and mechanical property requirements of ASTM A105, A182, or A350.

They are available in three pressure ratings: Class 3000, 6000 and 9000.

ASTM A182-ASME SA182-Standard specification for wrought austenitic stainless steel piping fittings ASME B16.9- factory-made wrought butt welding fittings ASME B16.11-forged fittings,socket-welding and threaded MSS SP-43-wrought and fabricated butt-welding fittings for low pressure,corrosion resistant applications MSS SP-95- swage(d) nipples and Bull Plugs BS3799-specification for steel pipe fittings, screwed and socket-welding for the petroleum industry

Forged Socket Weld Stainless Steel Fittings

Stainless Steel – ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

The material for forged stainless steel fittings conforms to ASME A182

The dimensions for forged stainless steel fittings conform to ASME B16.11

Forged Socket Weld Carbon Steel Fittings

Carbon Steel ASTM A105, A350 LF2, A106 Gr.B, A234 WPB

The material for forged carbon steel fittings conforms to the requirements of ASTM/ASME A105/SA105 The dimensions for forged carbon steel fittings conform to ASME B16.11