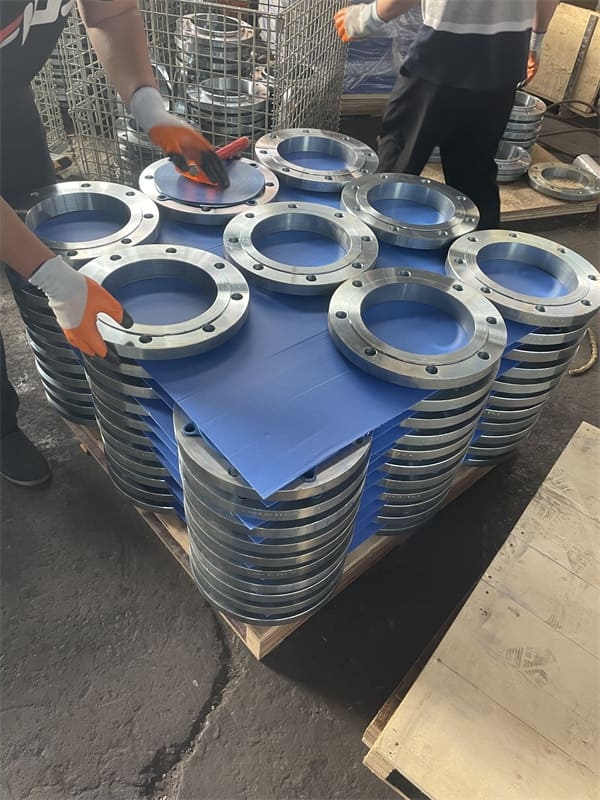

300# Stainless Steel Flange 2 inch Weld Neck Flange

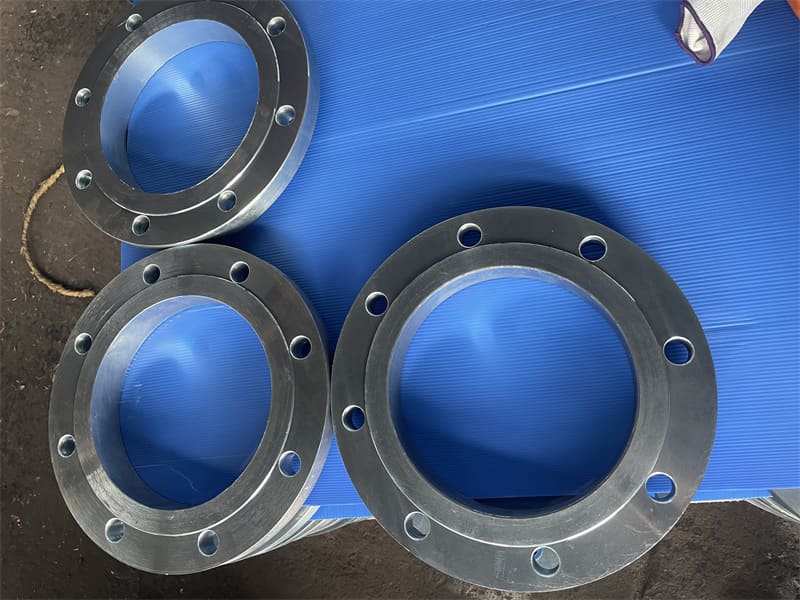

High Pressure Weld Neck Pipe Flange

A WN / weld neck flange, also called a tapered hub flange or high-hub flange, is a kind of flange that can relocate stress to the pipes, ensuring a decrease in high-stress concentration at the bottom of the flange. There are two welding neck flanges designs – the first type is used with wipes while the second, longer type cannot be used with pipes but with a process plant. The weld neck flange comprises of a round fitting that extends beyond the rim of the circumference. These flanges, typically manufactured from forging, are actually welded to pipes.

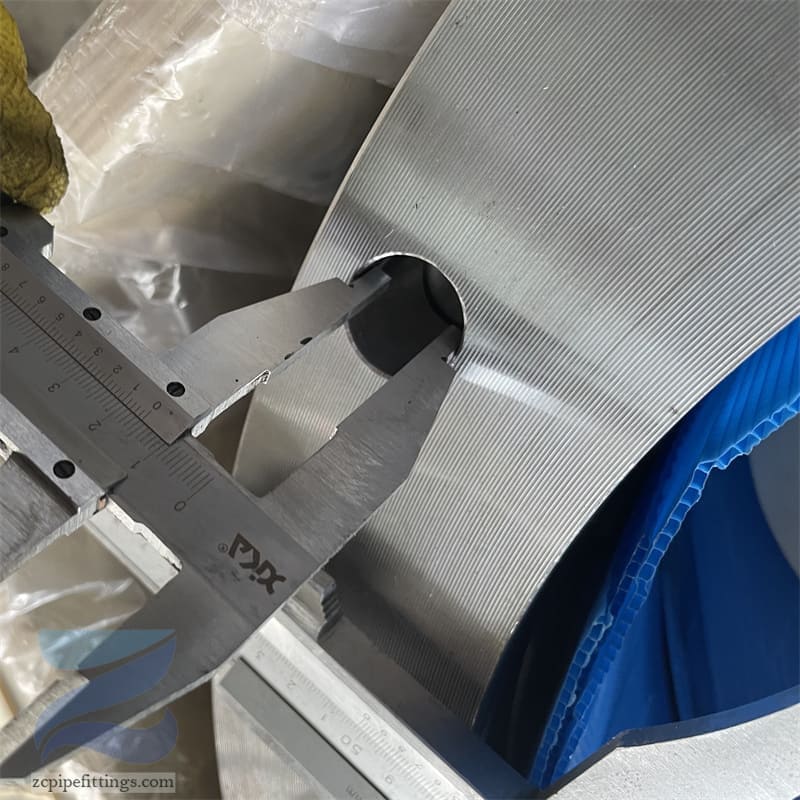

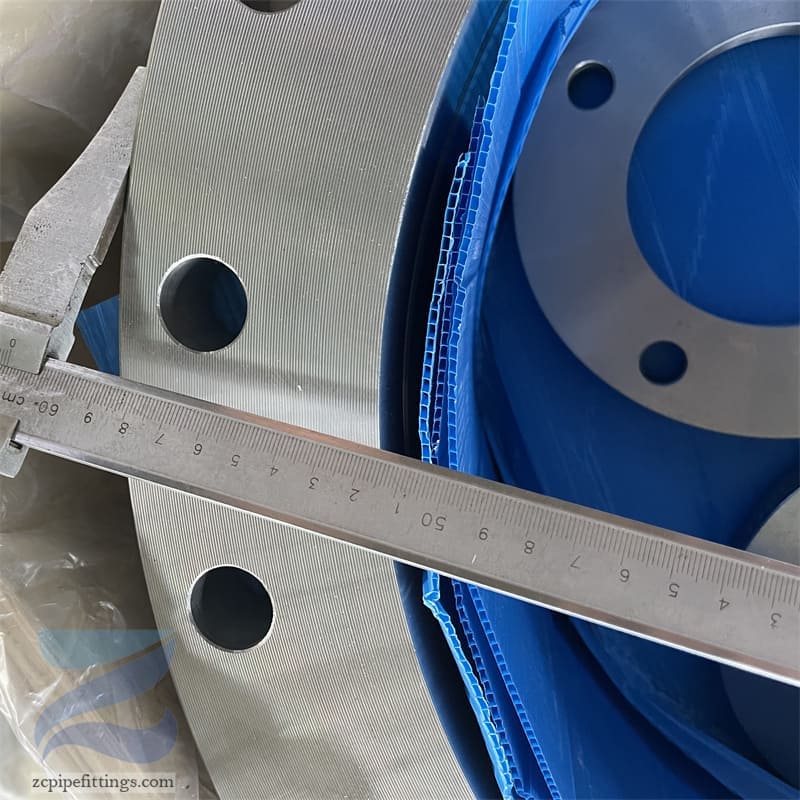

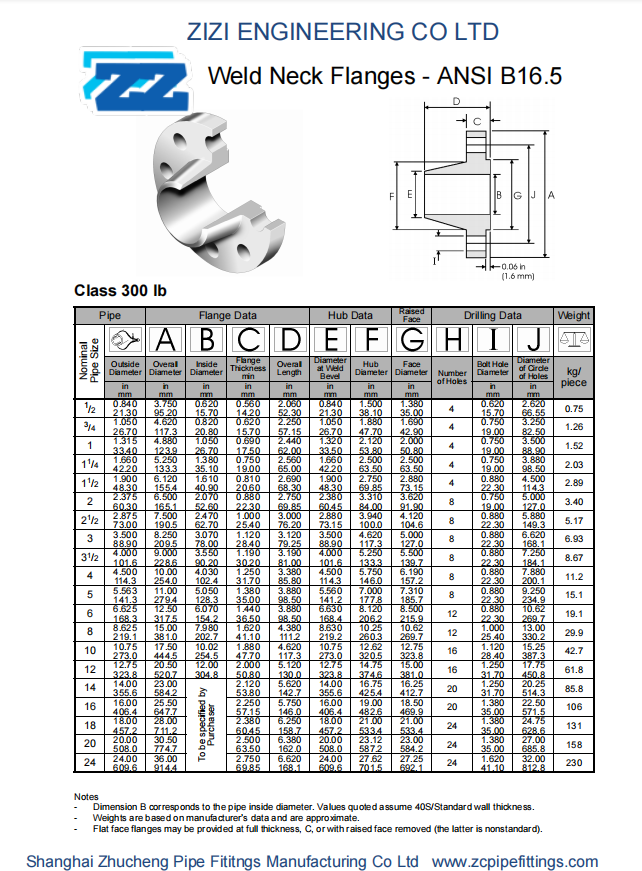

The Drawing for 300# WN/Weld Neck Flange

The difference of carbon steel flange and stainless steel flange

Carbon steel flange, that is, the body material is carbon steel plate or end flange connection. The flanges containing carbon steel are called carbon steel flanges. Common materials are carbon steel ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH. Besides carbon steel flanges, we also supply alloy steel flanges and stainless steel flanges .

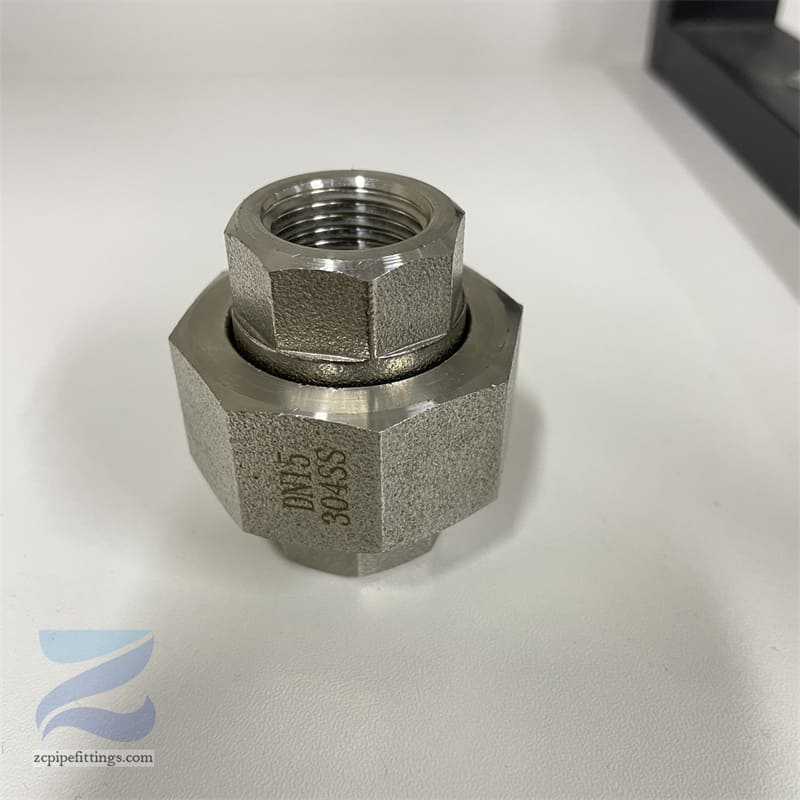

Stainless steel flange, also called SS flange, it means the material of flange is stainless steel. Common material standards and Grades are ASTM A182 Grade F304/L and F316/L, with pressure ratings from Class 150, 300, 600 etc and to 2500. It used in more industries than carbon steel as stainless steel has better resistant performances on corrosion environment and always provides with a good appearance.

There are varies advantages of stainless steel flange:

Resistant to corrosion and staining

Low maintenance

Bright familiar luster

Steel Strength

| Forged Steel Flanges Specification | |

| Shape | Weld Neck Flange ( WN),Slip-on Flange (SO), Threaded Flange (THD),Socket Weld Flange (SW),Blind Flange (BL),Lap Joint Flange (LAPJ),Plate flange (PL) |

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ASME B16.5, ASME B16.47 Series A/B, EN 1092-1, API 605, MSS SP-44, DIN 2627, DIN 2527, DIN 2558, DIN 2576, DIN 2641, DIN 2655, DIN 2656, DIN2573 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |