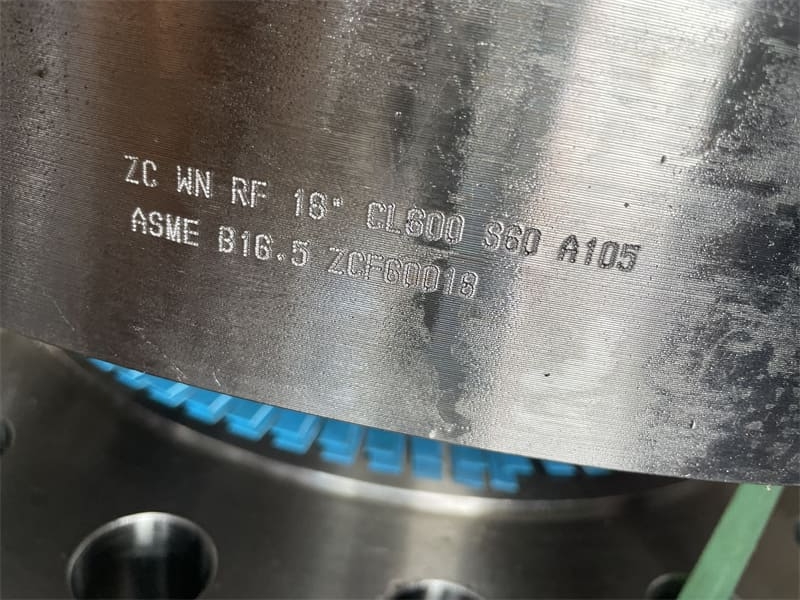

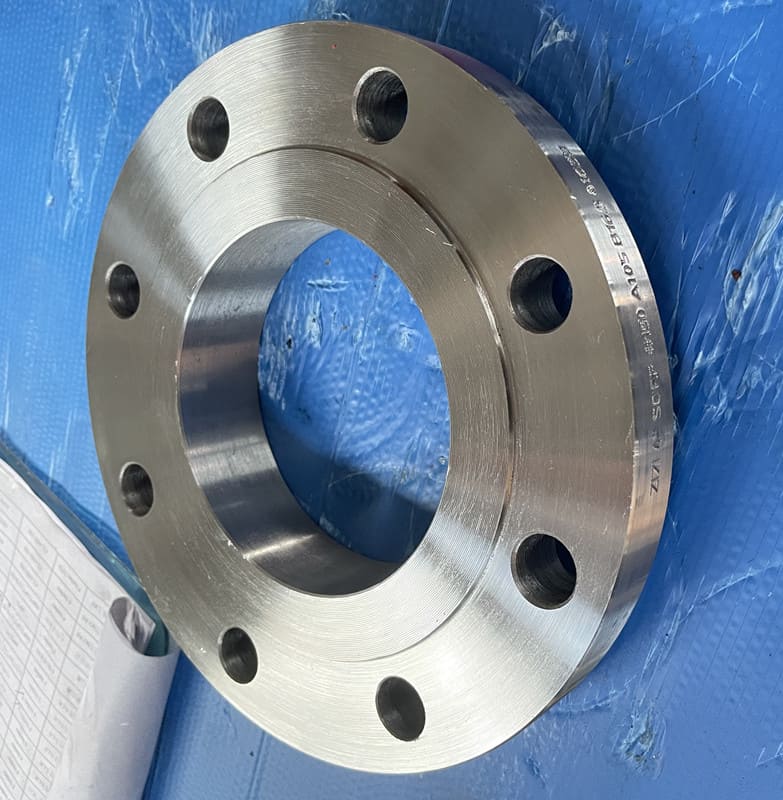

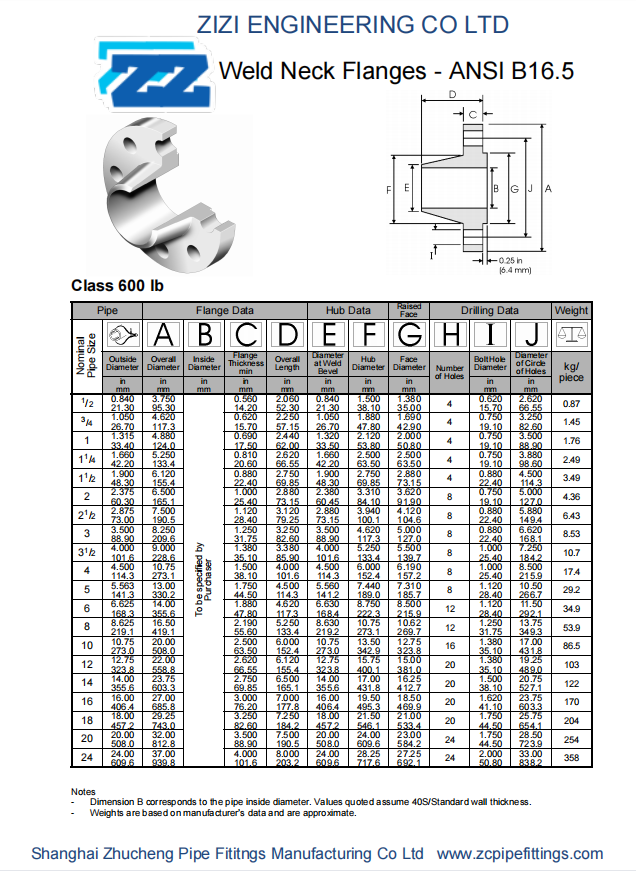

18IN CL600 WN Flange ASME B 16.5

18in CL600 WN flange is belong to large dimension flanges.ASME B16.5 is standard for forged flanges.Forged flanges have important functions in high pressure enverionments.

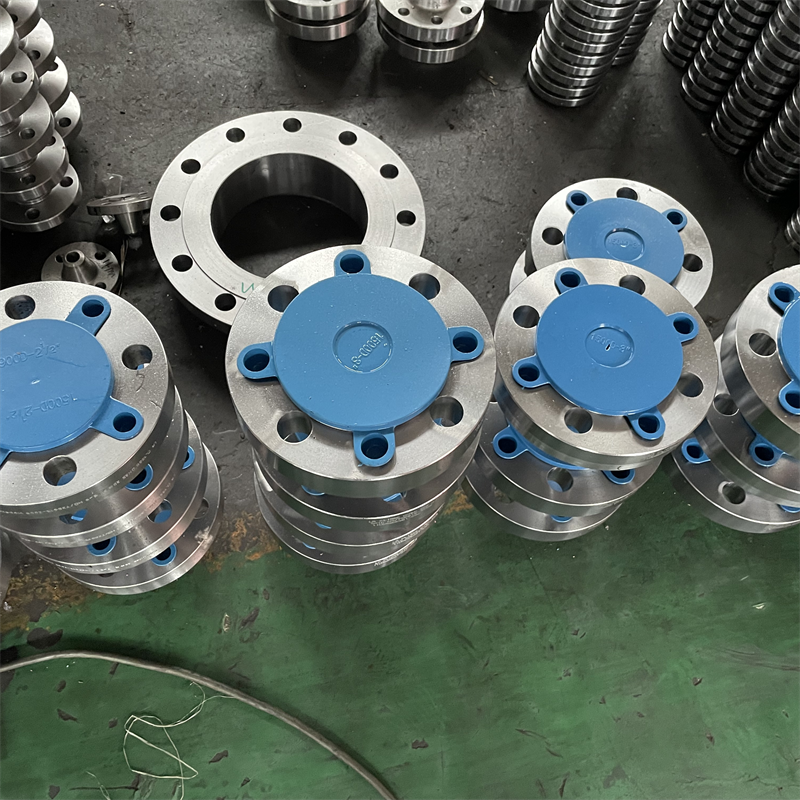

18in CL600 WN (Weld Neck) flanges are one type of large diameter forged flanges,these flanges always used in high pressure envrionment in many insdustries.ASME B 16.5 is the most used standard for flanges.

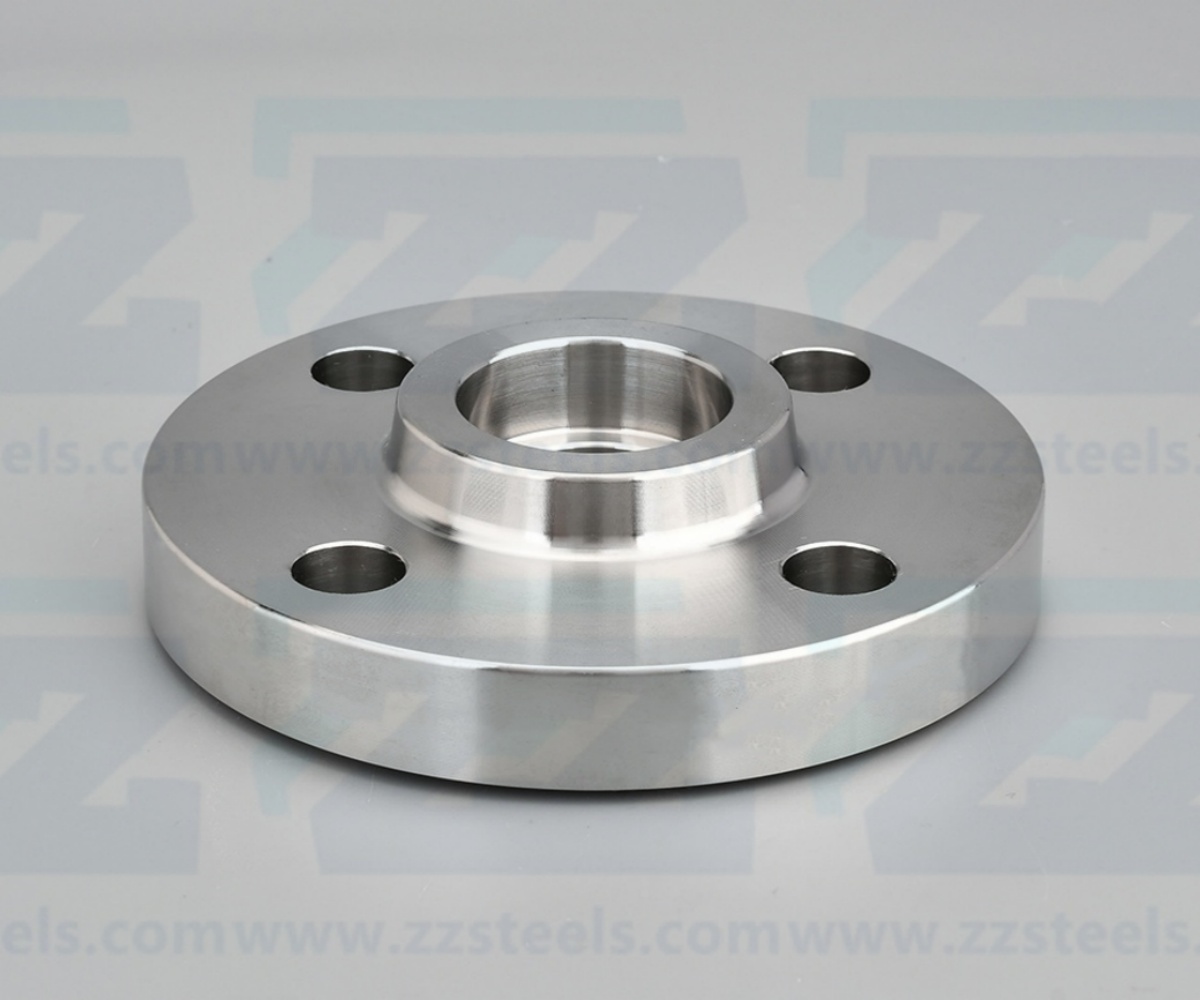

A weld neck flange (also known as a high-hub flange and tapered hub flange) is a type of flange. Weld Neck Flange is easy to recognize at the long tapered hub, that goes gradually over to the wall thickness from a pipe or fitting.

A weld neck flange consists of a circular fitting with a protruding rim around the circumference. Generally machined from a forging, these flanges are typically butt welded to a pipe. The rim has numerous holes drilled into it that enables the flanged to be attached to a bolted flange. This design is far better because of the structural valve.

Types:

Standard: used in butt weld fittings.

Long: used with vessel nozzles and equipment,used on vessels, columns or barrels.

Facing:

Flat Face Full Face (FF), Raised Face (RF), Male Face(M), Female Face (FM), Tongue Face(T), Groove Face (G), Ring Joint Face ( RTJ/ RJ ).

SPECIFICATION

| Shape | Weld Neck Flange ( WN) |

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ASME B16.5, ASME B16.47 Series A/B, EN 1092-1, API 605, MSS SP-44, DIN 2627, DIN 2527, DIN 2558, DIN 2576, DIN 2641, DIN 2655, DIN 2656, DIN2573 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Advantages:

- Unrestricted product flow

- Prevents turbulence at the joint and reduces erosion

Applications:

The long tapered hub provides an important reinforcement for use in several applications involving high pressure, sub-zero and / or elevated temperatures.

Such flanges are suitable for use in hostile environments that have extremes of temperature, pressure or other sources of stress. This type of flange has been used successfully at pressures up to 5,000 psi.

Weld Neck Flange VS Slip On Flange

The Weld Neck Flange offers increased strength under higher pressures, subzero or elevated temperatures that cause line expansion or retraction or other variable forces. The Slip On Flange is connected to the pipe by two welds, one on the back side of the Flange and one on the inside of the Flange.